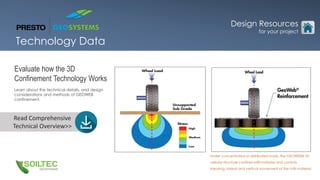

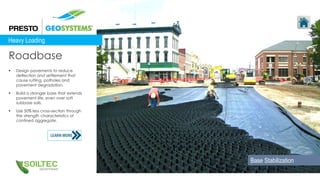

This document provides resources for designing roads and pavements using the GEOWEB load support system. It includes an overview of how the system works, comparisons to other systems, specification tools, CAD drawings, videos, technical evaluations, and information on applications across different markets and industries. The goal is to equip engineers with all the tools and resources needed to design higher-performing roads and pavements.