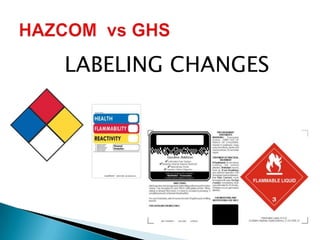

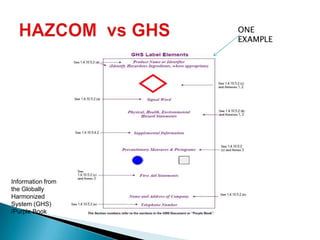

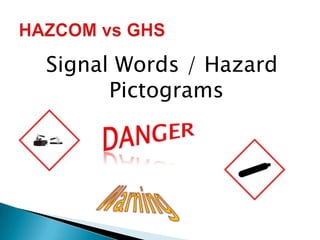

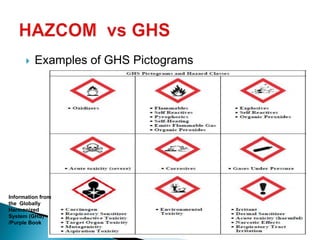

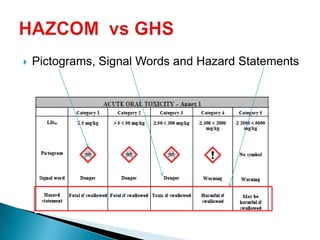

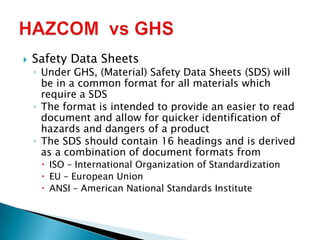

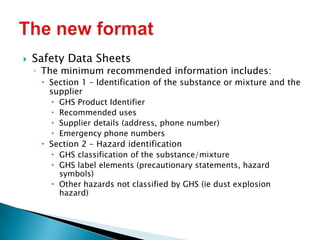

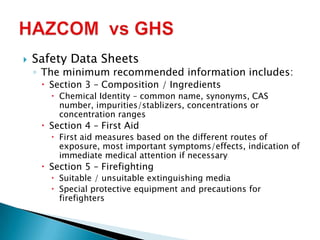

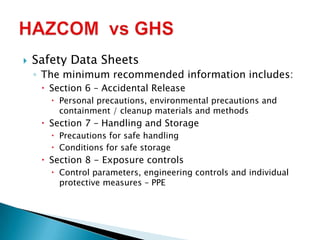

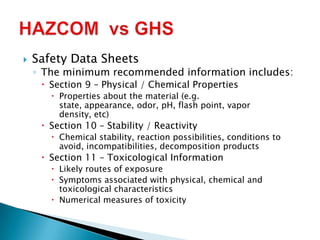

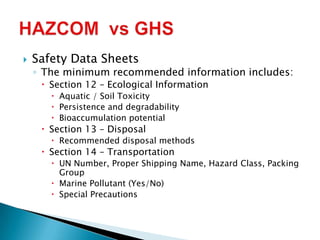

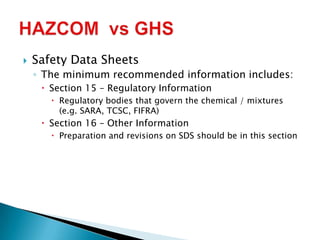

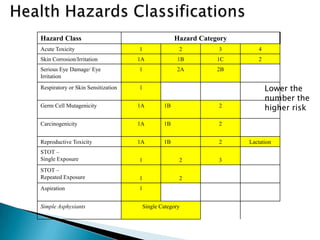

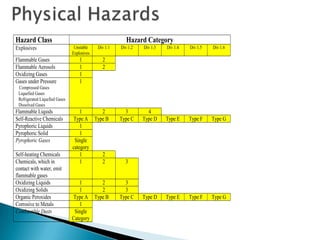

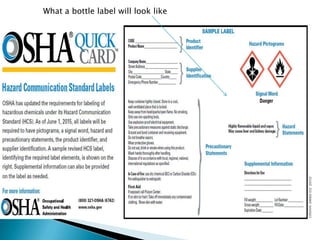

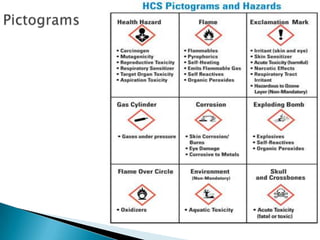

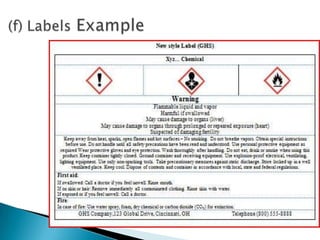

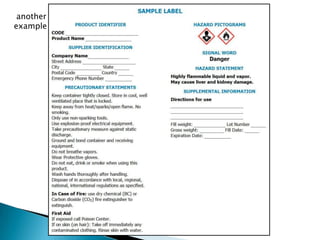

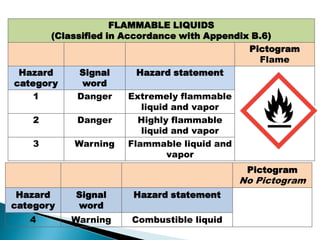

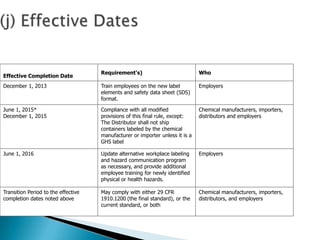

This document outlines an organization's hazard communication system and chemical safety policies and procedures. It discusses training employees about chemicals in the workplace on a yearly basis or when new chemicals are introduced. Safety data sheets will be kept and available for all chemicals. No new chemicals will be used without an approved safety data sheet. Chemicals must be stored and labeled properly and never mixed together. The document also reviews new global standards for labeling hazardous materials using pictograms and standardized format for safety data sheets.