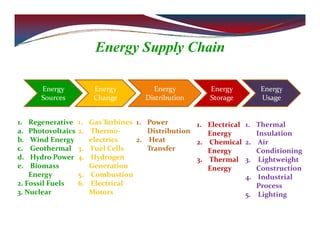

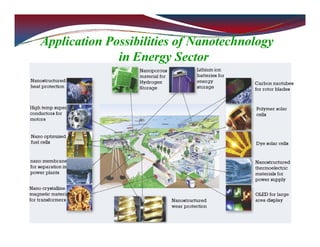

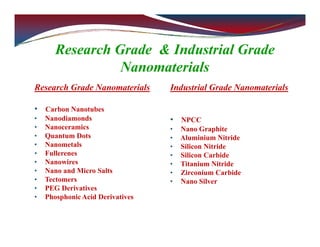

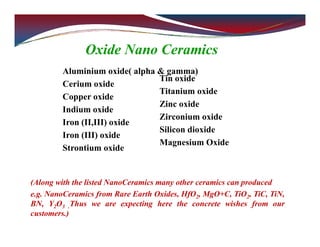

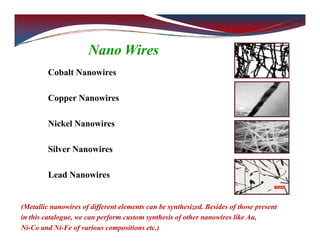

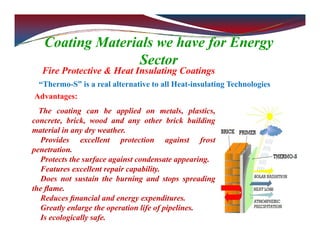

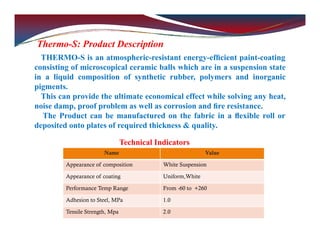

Reinste Nano Ventures provides nanomaterials and coatings for use in the energy sector. They offer a wide range of research-grade and industrial-grade nanomaterials including carbon nanotubes, quantum dots, and ceramics. Their coatings include fire protective and heat insulating coatings as well as self-healing coatings to improve durability. Nanotechnology can enhance energy efficiency across the supply chain from sources to storage and usage.