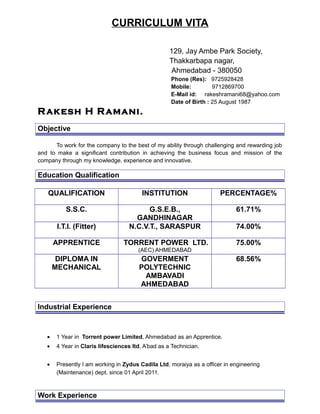

Rakesh Ramani is seeking a position that allows him to fully utilize his knowledge and experience. He has over 10 years of experience in maintenance roles for pharmaceutical companies. He has worked with various machinery used in formulation, parental, and project departments, including tablet compression machines, packaging equipment, granulation devices, filling machines, and more. Rakesh holds qualifications in fitting from ITI and mechanical engineering from polytechnic, and seeks to make a significant contribution to a company through innovative problem solving.