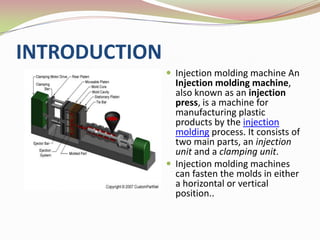

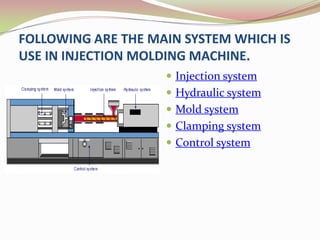

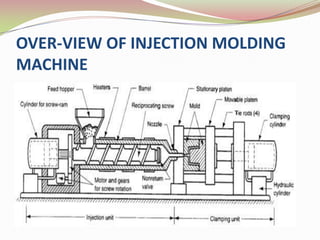

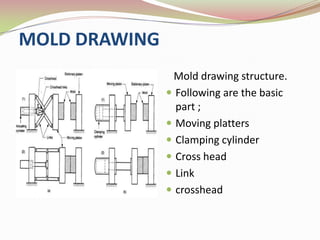

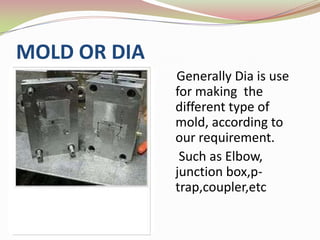

This document discusses Nasir Azmi's responsibilities as an assistant supervisor of injection molding machines at Diplast Ltd. It provides an overview of injection molding, describing the basic parts and systems of injection molding machines. It also outlines Nasir's duties, which include minimizing scrap, ensuring quality, optimizing labor, and reducing mold change times. The document discusses applications of injection molding and provides information on common plastics used in the process like PVC.