MY CV STEWART N.

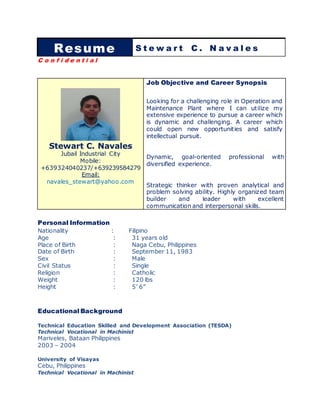

- 1. Resume S t e w a r t C . N a v a l e s C o n f i d e n t i a l Stewart C. Navales Jubail Industrial City Mobile: +639324040237/+639239584279 Email: navales_stewart@yahoo.com Job Objective and Career Synopsis Looking for a challenging role in Operation and Maintenance Plant where I can utilize my extensive experience to pursue a career which is dynamic and challenging. A career which could open new opportunities and satisfy intellectual pursuit. Dynamic, goal-oriented professional with diversified experience. Strategic thinker with proven analytical and problem solving ability. Highly organized team builder and leader with excellent communication and interpersonal skills. Personal Information Nationality : Filipino Age : 31 years old Place of Birth : Naga Cebu, Philippines Date of Birth : September 11, 1983 Sex : Male Civil Status : Single Religion : Catholic Weight : 120 lbs Height : 5’ 6” Educational Background Technical Education Skilled and Development Association (TESDA) Technical Vocational in Machinist Mariveles, Bataan Philippines 2003 – 2004 University of Visayas Cebu, Philippines Technical Vocational in Machinist

- 2. June 2001 – March 2002 (Under-graduated) Naga Elementary School Naga, Cebu Philippines 1991 – 1996 Resume of Stewart C. Navales Professional Experience Mechanical Technician (Saudi Arabian Fertilizer Co.) SAFCO / Ibn Al-Baytar Mechanical Technician from September 2008 - 2013 A SABIC Affiliate, Jubail Industrial City - Saudi Arabia Duties & Responsibilities • Responsible for Maintenance and repair of all plant equipments. • Overhauling jobs on air compressors, Steam turbines, Centrifugal pumps, plunger pumps, Gear boxes and other rotating equipments. • Troubleshoot and replacement of governors, Mechanical seals, Oil Seals. • Preventive maintenance of all rotating equipments. Such as Oil level checking and refilling, Checking of bearing clearance, Alignment of equipment, Oil filter replacement. • Participants on decision making prior to troubleshooting of equipment. • Perform preventive, predictive and scheduled maintenance on mechanical equipment. • The main Purpose of the job is to provide support to the maintenance of all rotating and static equipment. • Follow maintenance and repairs procedures as per specified standards to ensure integrity and safety of mechanical systems and equipment. • Carry out routine maintenance checks and report/resolve any faults or abnormalities of equipment • Troubleshoot breakdowns and execute repairs • Report to the Foreman / Engineer • Execute the different tasks programmed and planned according to the procedure and the preservation plan. • Responsible for implementing effective equipment maintenance / overhaul of specified equipment in accordance with company and vendor procedures so

- 3. as to facilitate maximum reliability, availability and safety of the equipment (valves, compressors, pumps, vessels, heat exchangers, fans, piping etc.) • Implement the safe and efficient maintenance of mechanical systems and equipment in accordance with the agreed maintenance and safety procedures. • Direct temporary contract labor so as to ensure safe and effective implementation of daily duties. • Responsible for installation and or modifications of mechanical equipment for use in hazardous and non-hazardous locations, ensuring all safety regulations have been followed. • Assists Sub-Contractor performing preventive maintenance of the Diesel Generators and any other Equipment. • Investigations in the event of mechanical equipment failure. • Warns Maintenance Superintendent about any recurring problems related to the availability or quality of spares parts. • Work under & less supervision. Resume of Stewart C. Navales Arabian Petrochemical Company Petrokemya Mechanical Technician from August 2007 – July 2008 A SABIC Affiliate, Jubail Industrial City - Saudi Arabia Duties & Responsibilities • Spare parts fabrication of worn-out parts of plant machineries such as motors, pipes, pumps, bolts, bushings and etc. • Straightening of metal/stainless shafting • Able to read and understand drawings. • Troubleshooting/preventive maintenance in 8 manufacturing plants. • Maintain the operational integrity of maintenance (preventive maintenance), installation and removal of mechanical systems/components repair and documentation of the production system. • Troubleshoots down to the component level. With the ability to make repairs to system and perform test to validate repairs • Maintains a high standard of safety and housekeeping to ensure area, machines and equipment are maintained in a safe and clean condition. Corrects and/or reports unsafe conditions and other faults. • Follow Preventive maintenance requirements and identify issues while making inspections. • Maintain cleanliness of workplace including machineries and tools after work.

- 4. Orica Philippines, Inc. Machinist from January 2003 – 2006 Limay Bataan, Philippines Duties & Responsibilities • Spare parts fabrication of worn-out parts of plant machineries such as motors, pipes, pumps, bolts, bushings and etc. • Machine parts to specifications using machine tools such as lathes, milling machines, shapers, or grinders. • Measure, examine, and test completed units in order to detect defects and ensure conformance to specifications, using precision instruments such as micrometers. • Set up, adjust, and operate all of the basic machine tools and many specialized or advanced variation tools in order to perform precision machining operations. • Align and secure holding fixtures, cutting tools, attachments, accessories, and materials onto machines. • Monitor the feed and speed of machines during the machining process. • Study sample parts, blueprints, drawings, and engineering information in order to determine methods and sequences of operations needed to fabricate products, and determine product dimensions and tolerances. • Select the appropriate tools, machines, and materials to be used in preparation of machinery work. • Lay out, measure, and mark metal stock in order to display placement of cuts. • Observe and listen to operating machines or equipment in order to diagnose machine malfunctions and to determine need for adjustments or repairs. • Check workpieces to ensure that they are properly lubricated and cooled. • Maintain industrial machines, applying knowledge of mechanics, shop mathematics, metal properties, layout, and machining procedures. • Position and fasten workpieces. • Operate equipment to verify operational efficiency. • Install repaired parts into equipment, or install new equipment. • Clean and lubricate machines, tools, and equipment in order to remove grease, rust, stains, and foreign matter. • Advise clients about the materials being used for finished products. • Program computers and electronic instruments such as numerically controlled machine tools. • Set controls to regulate machining, or enter commands to retrieve, input, or edit computerized machine control media. • Confer with engineering, supervisory, and manufacturing personnel in order to exchange technical information. • Dismantle machines or equipment, using hand tools and power tools, in order to examine parts for defects and replace defective parts where needed.

- 5. • Establish work procedures for fabricating new structural products, using a variety of metalworking machines. • Support metalworking projects from planning and fabrication through assembly, inspection, and testing, using knowledge of machine functions, metal properties and mathematics. • Confer with numerical control programmers in order to check and ensure that new programs or machinery will function properly, and that output will meet specifications. • Fit and assemble parts to make or repair machine tools. • Evaluate experimental procedures, and recommend changes or modifications for improved efficiency and adaptability to setup and production. • Design fixtures, tooling, and experimental parts to meet special engineering needs. • Prepare working sketches for the illustration of product appearance. • Install experimental parts and assemblies such as hydraulic systems, electrical wiring, lubricants, and batteries into machines and mechanisms. • Set up and operate metalworking, brazing, heat-treating, welding, and cutting equipment. • Test experimental models under simulated operating conditions for such purposes as development, standardization, and feasibility of design. Machine Handheld • Universal milling machine. • Horizontal and vertical lathe machine • Surface grinder • Drilling machine Training and Seminars Attended • Safety, Health and Environment Management System • CLEAR Seminar • Critical Behavior Inventory (CBI) • Basic of Safety • Manual Handling • Pump Protection • First Aid & CPR • Confined Space • Permit Acceptor Copies of credentials and reference contacts can be forwarded when desired.