This document provides information about mussel farming techniques in India. It discusses the following key points:

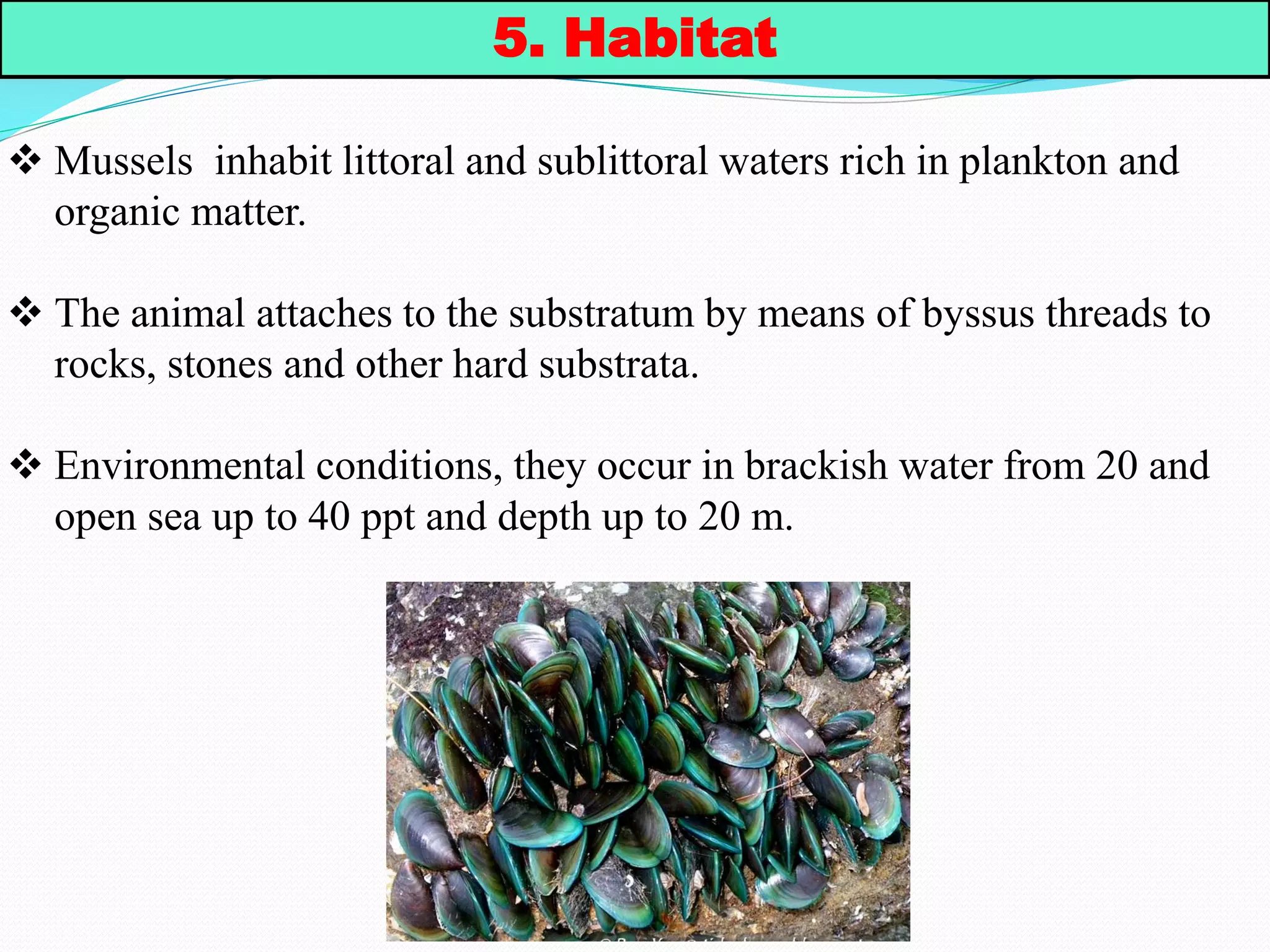

1. China is the world's largest producer of cultured mussels. In India, mussel culture is popular along the Malabar coast, where the two main species farmed are Perna viridis and Perna indica.

2. Common mussel farming techniques used in India include raft culture, rack culture, and long-line culture. Raft culture is conducted in deep coastal waters using rafts up to 8x8 meters with seeded ropes suspended below.

3. Rack culture is used in shallow waters up to 3 meters deep, using wooden frames built on poles to suspend seeded ropes or bags