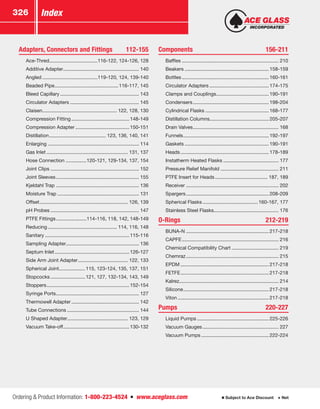

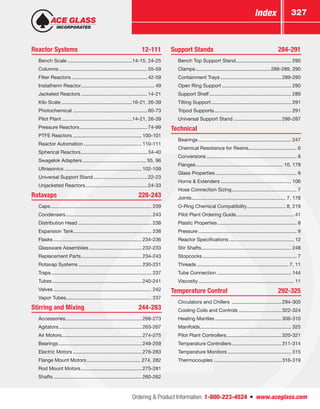

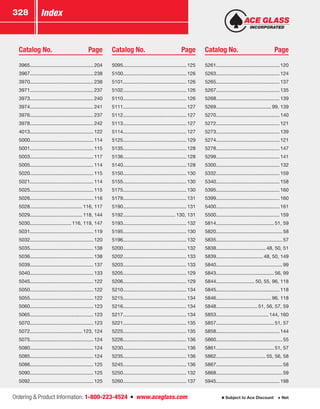

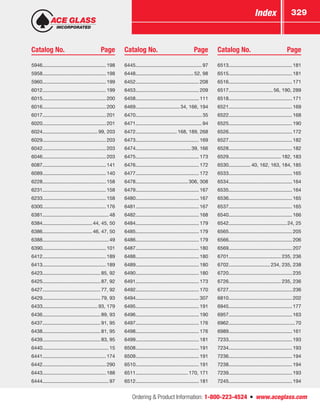

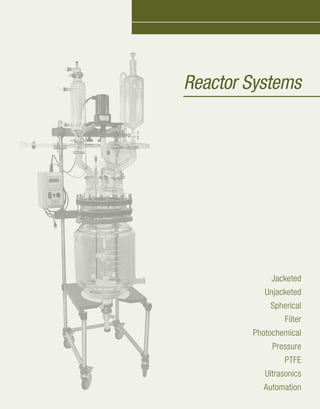

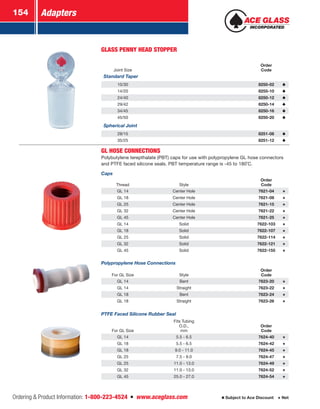

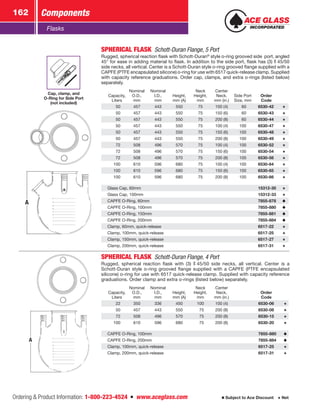

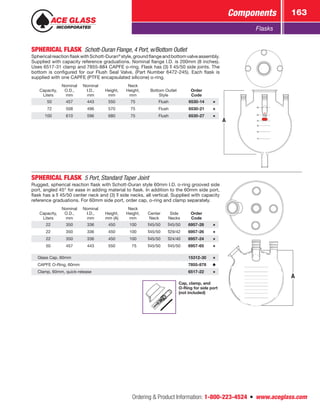

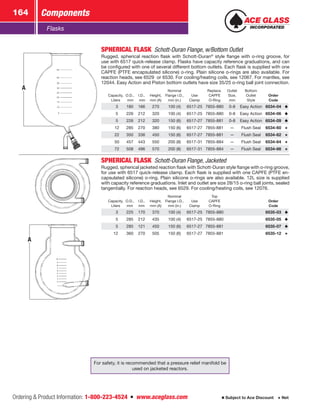

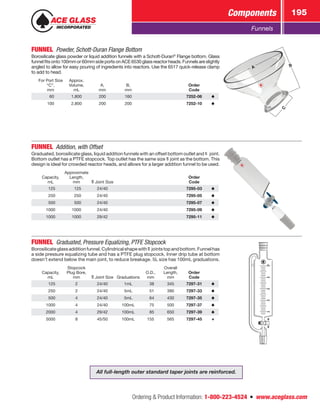

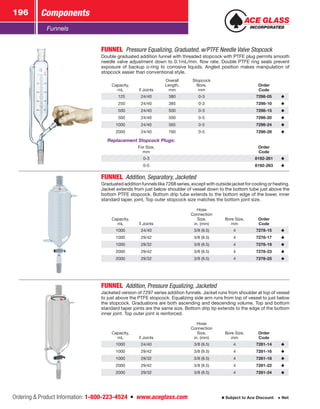

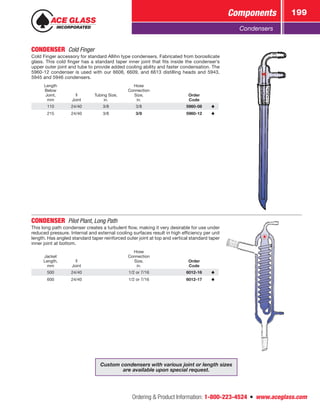

This document provides information about process scale-up systems from Ace Glass featuring reactors from micro to batch scale for applications in various industries such as life sciences, pharmaceutical, and petrochemical. It lists general specifications for Ace Glass products and information on ordering, payment, shipping, returns, and technical support. The document also provides contact information for Ace Glass and its distributors in North America and internationally.

![Ordering Product Information: 1-800-223-4524 n www.aceglass.com

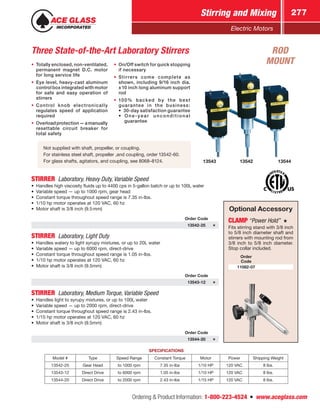

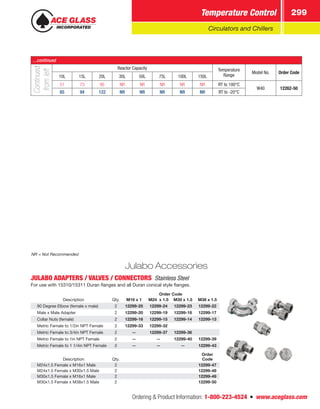

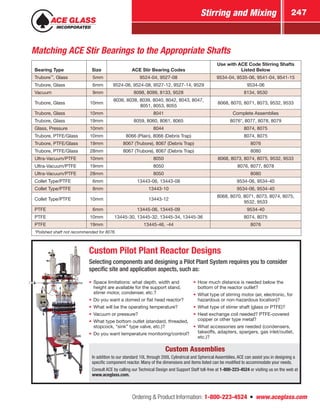

Stirring and Mixing276

Subject to Ace Discount Net

Electric Motors

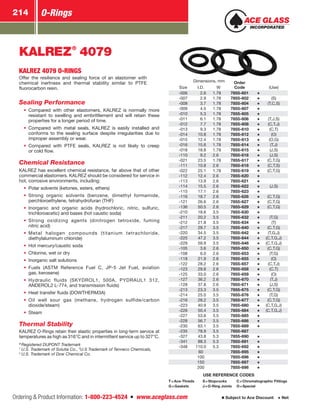

13511-02

RZR Control

Electronic

Series

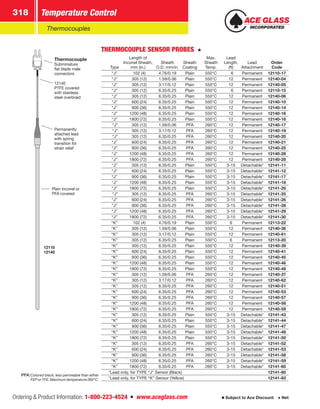

•• Digital speed display

•• Two gear stages for constant speed

•• Overheating protection — self reset

•• Over-load protection LED display

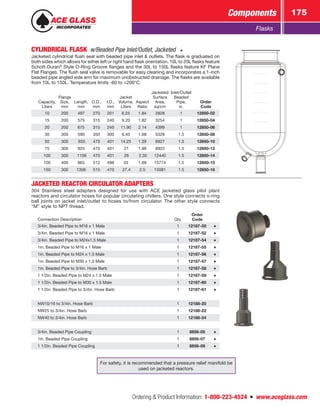

Similar to “Standard Series,” except with added features such as constant power. The

electronic automatic control allows almost constant torque over respective speed range.

The two-stage gear provides excellent mixing results even in highly viscous media, using

only as much energy as actually needed. The speed desired is kept constant under changing

loads, even in overload mode. (Power can be increased for a limited time to 175% or 200%,

so there is no premature cutoff when overloaded.)

Changes in viscosity during the process can be followed via a digital display of the torque

on both 13507 and 13511. Also, both models are equipped with an analog interface enabling

output of speed and torque reading to an external device (such as a chart recorder), or

specification of the desired speed via PC. Analog speed and torque output, along with

computer controllability (speed), is 0-10 V/4-20 mA. See 8126-22 or 8126-24 adjustable

pass-through chuck assemblies.

STIRRERS Heidolph®

RZR Control Series

Number of Gears 1 2

Speed Range [rpm] 50–2000 12–400, 60–2000

Speed Display Digital Digital

Torque Display Digital Digital

Controller Response Constant rpm under changes in viscosity

Overload Response Constant rpm under overload

Max. Torque (continuous/limited) [in-lb] 13.91/31.02 27.81/48.14

Torque at 100/1000 rpm [in-lb] 13.37/2.67 26.74/5.35

Power Reserve under Overload up to 200% up to 200%

Max. Viscosity [cp] 10,000 100,000

Max. Mixing Volume (H2

0) [Liters] 20 40

Dimensions (W x H x D) mm

in.

72 x 206 x 176

3.23 x 8.1 x 6.9

82 x 211 x 176

3.23 x 8.3 x 6.9

Weight [Kg/lbs] 2.8/6.17 3.7/8.16

Input Power* 115v/60Hz 115v/60Hz

Motor Input/Output [Watts] 80/50 140/100

Heidolph Model 2051 2102

Order Code 13507-51 13511-02

*230V/50Hz version also available. 13507-51 not pictured.

ROD

MOUNT](https://image.slidesharecdn.com/0c329eaf-2664-4e32-a56e-6a1b7a8d5f17-161020193021/85/MP2000Reactor-276-320.jpg)