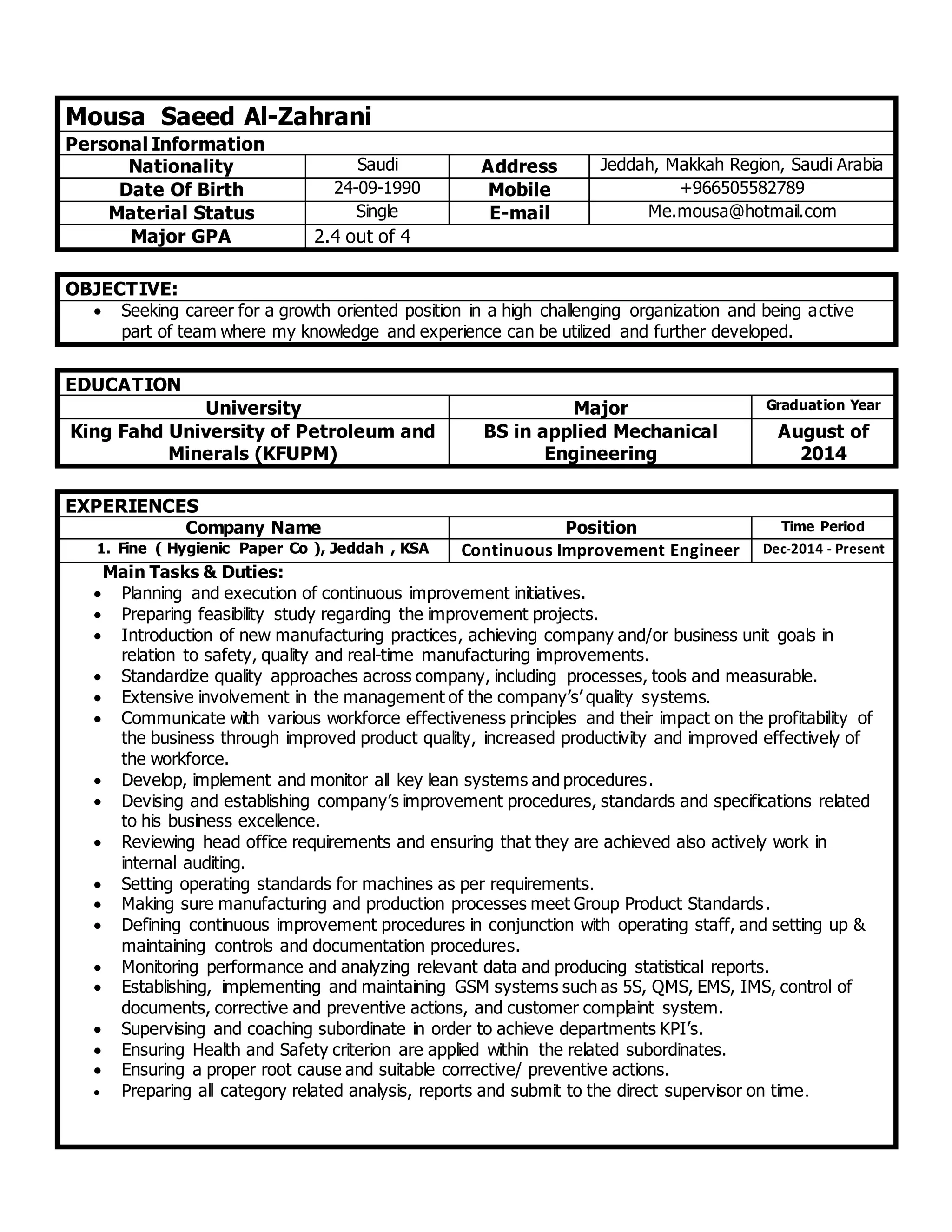

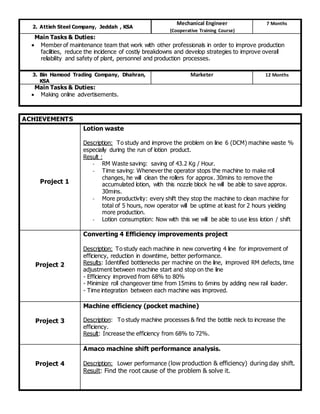

Mousa Saeed Al-Zahrani is a Saudi national seeking a career opportunity where he can utilize his knowledge and experience. He has a bachelor's degree in applied mechanical engineering and over 5 years of work experience in continuous improvement engineering, mechanical engineering, and marketing. His experience includes implementing lean systems and quality improvement projects that increased efficiency and reduced waste and costs.