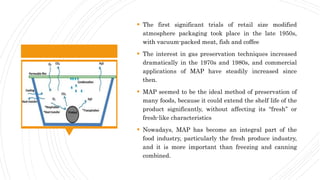

Modified atmosphere packaging (MAP) involves adjusting gas levels to extend food shelf life and maintain quality, with historical roots dating back to ancient practices. It utilizes gases like nitrogen, oxygen, and carbon dioxide to control microbial growth and reduce spoilage, and has become integral to the modern food industry. While MAP offers benefits such as convenience and reduced necessity for preservatives, it also poses challenges such as the need for specialized equipment and careful gas formulation.