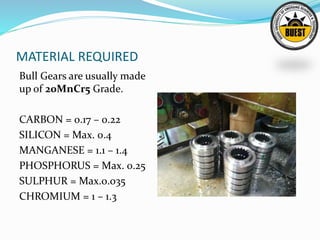

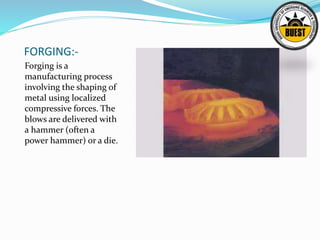

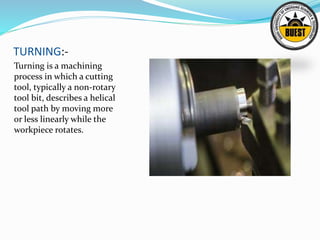

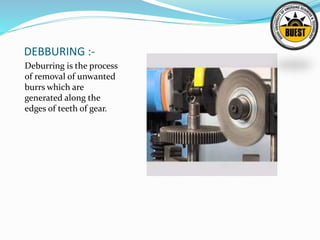

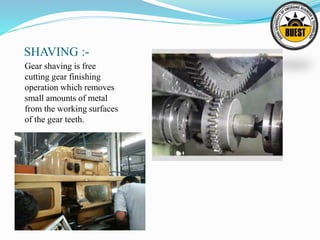

Him Teknoforge Ltd. is a prominent manufacturer of forgings and machined components, primarily bull gears, established in 1982. The document outlines the materials, applications, and various manufacturing processes involved in producing bull gears, as well as the tools used for quality inspection. The author reflects on their industrial training experience, emphasizing the importance of discipline and knowledge in a workshop setting.