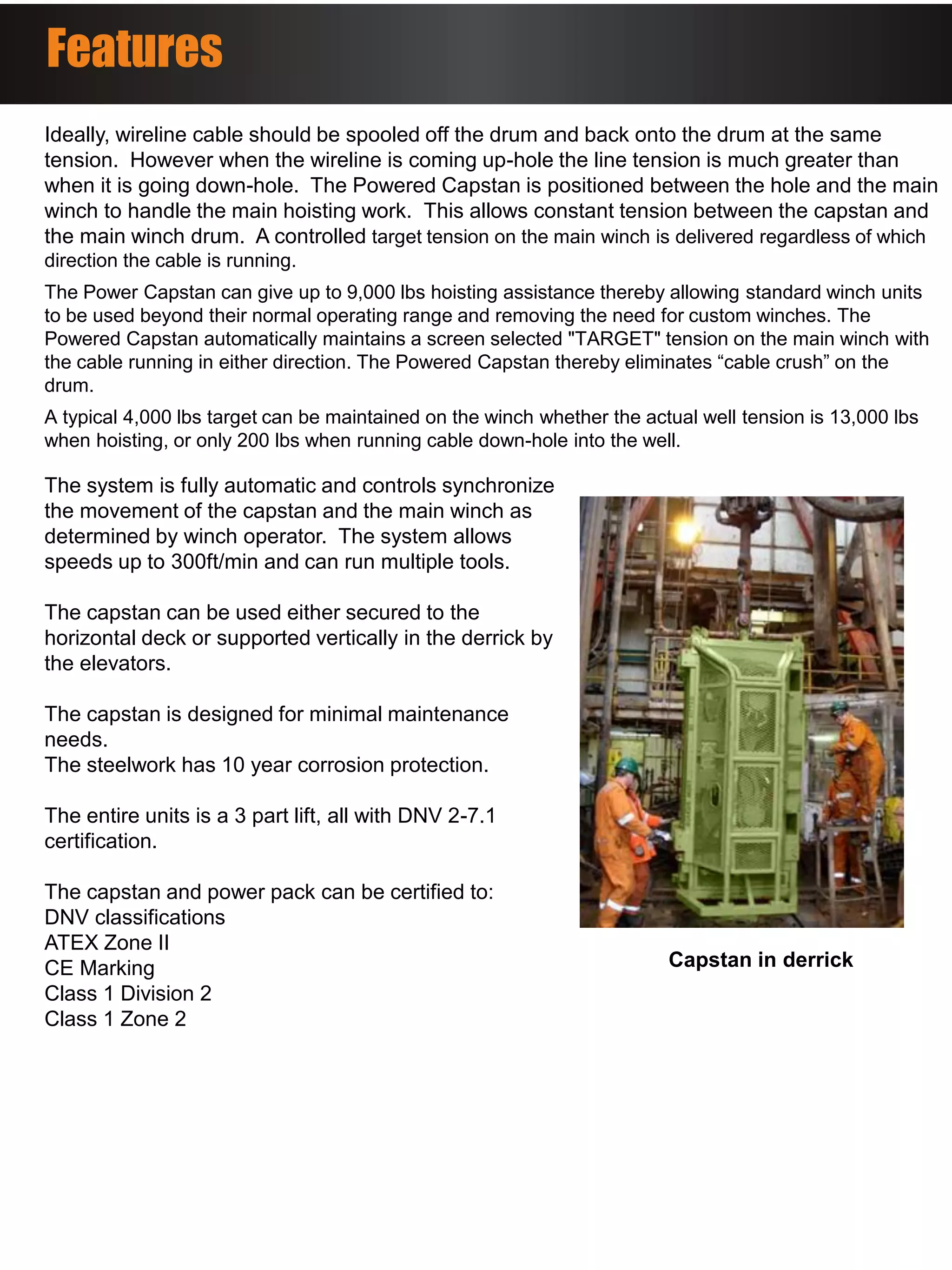

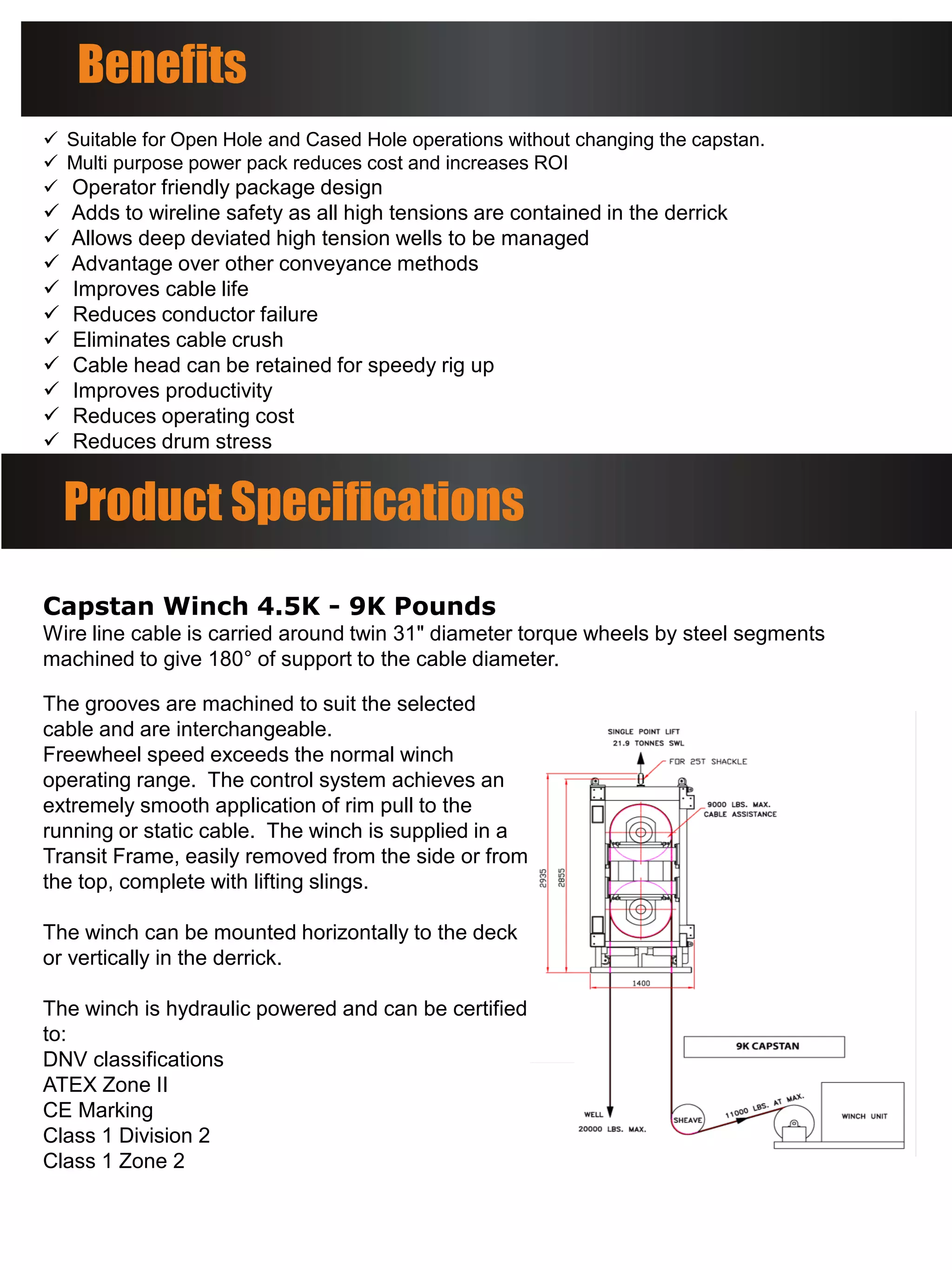

The document discusses powered capstans, which are traction winches that provide additional lifting force on cables to augment lifting capacity, stabilize tension, and reduce cable crush. It specifically describes the MK-8 capstan, which can provide working tensions from 0-4500 lbs and 0-9000 lbs to assist with cased hole operations. The capstan is positioned between the well and main winch to handle hoisting work and allow constant tension regardless of cable direction. Key benefits include reducing spooling tension, drum loading, and cable crush while providing additional line pull.