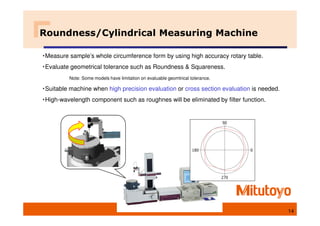

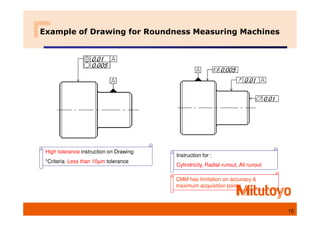

Measuring instruments must be chosen based on the dimensional and geometric tolerances specified on engineering drawings. Drawings may indicate requirements such as surface roughness measurements, tight cylindrical tolerances, or evaluating small features that require a microscope or vision measuring system. Coordinate measuring machines are suitable for complex 3D parts with many defined elements and dimensions. Roundness testing machines effectively measure whole circumference profiles. Hardness testers evaluate mechanical properties. Selecting the right instrument ensures accurate evaluation of the critical specifications for a workpiece.