This document provides ordering and product information for various gearhead models:

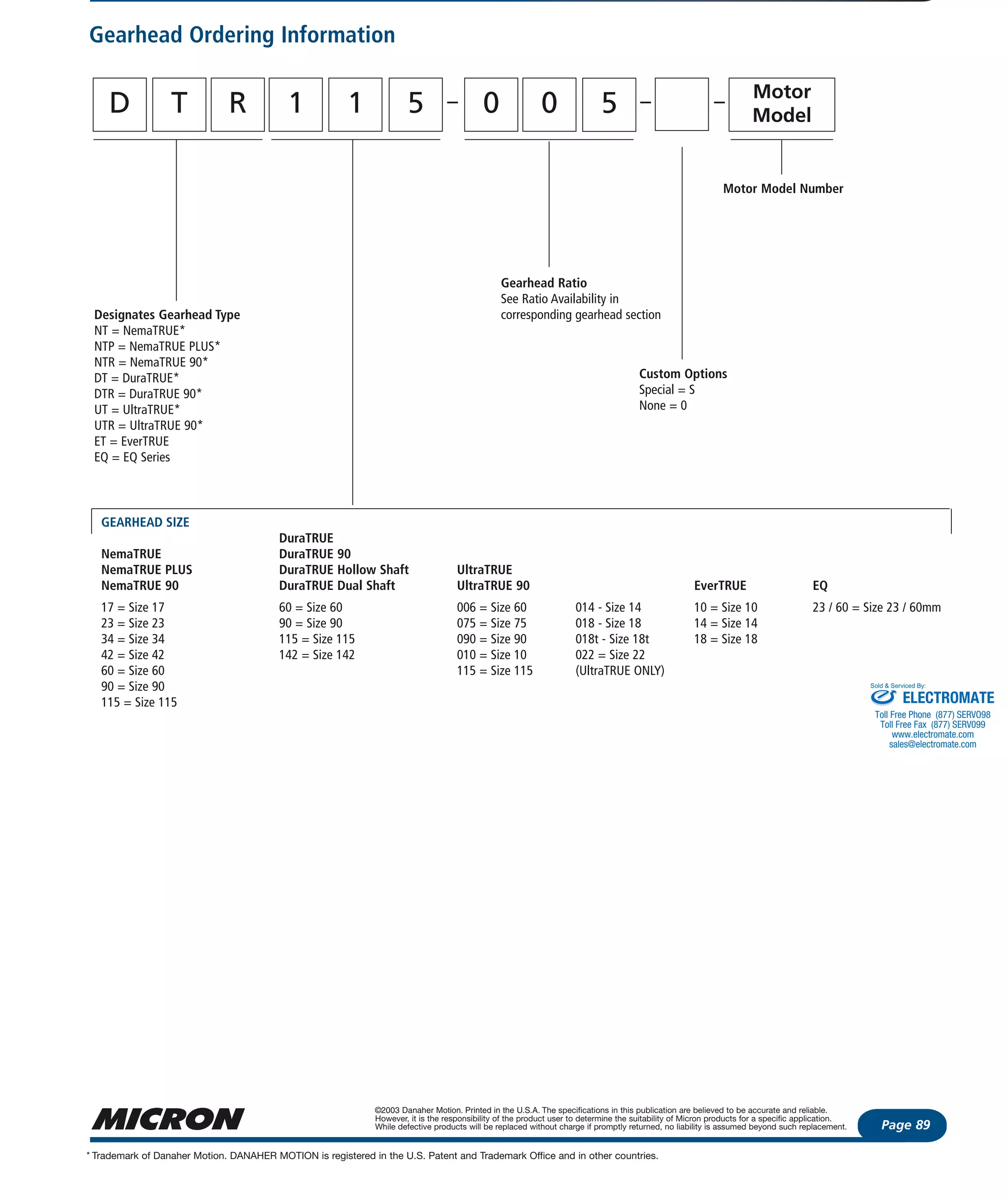

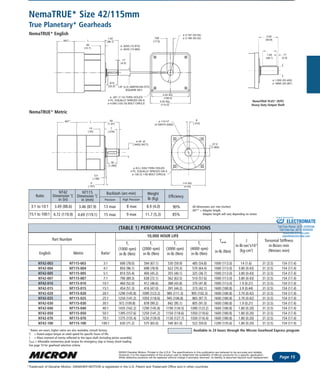

- It describes how to order gearheads, listing available models, sizes, ratios, and customization options.

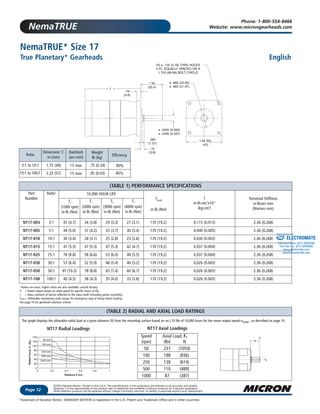

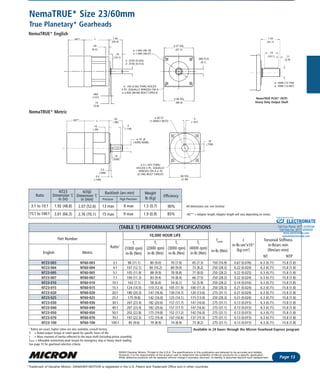

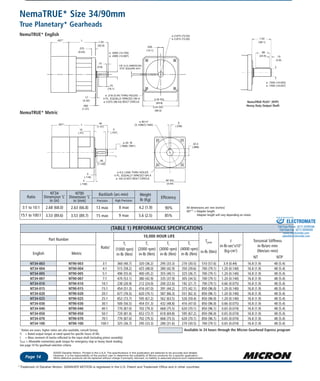

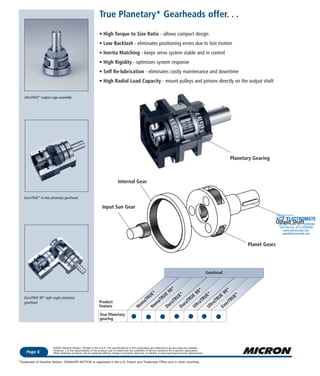

- Specifications are provided for each gearhead size, including dimensions, torque ratings, load capacity, precision, and other performance parameters.

- Contact and sales information is listed for the manufacturer.