The document provides information about various C-Face power-off brakes including:

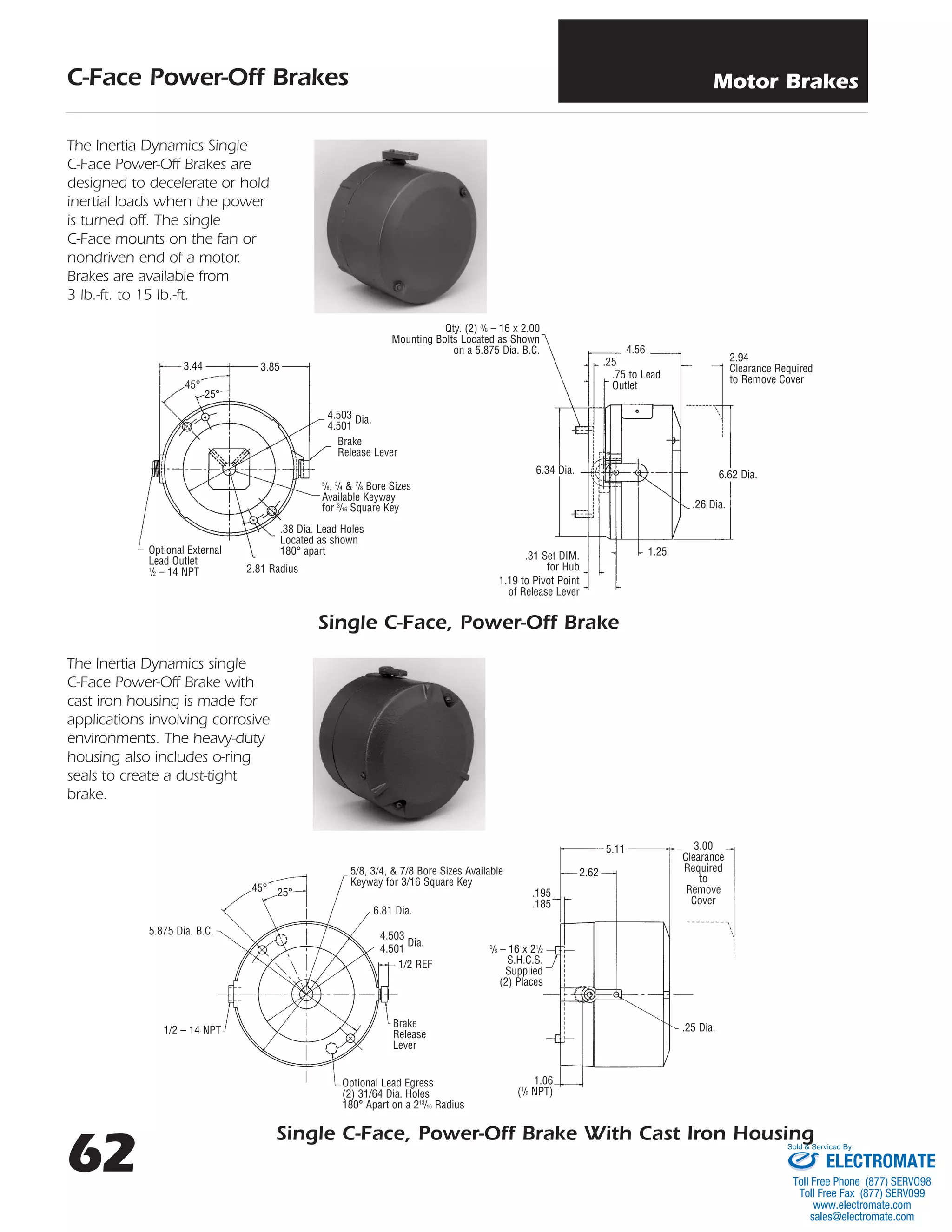

- A single C-Face, power-off brake that mounts on the non-driven end of a motor and is available from 3-15 lb-ft of torque.

- A single C-Face brake with a cast iron housing for corrosive environments that includes o-ring seals.

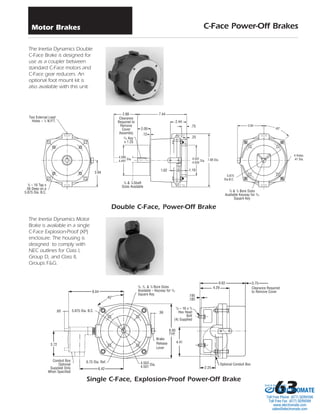

- A double C-Face brake designed for use as a coupler between C-Face motors and gear reducers, with an optional foot mount kit.

- An explosion-proof single C-Face brake enclosed for hazardous environments.