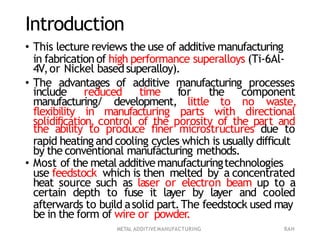

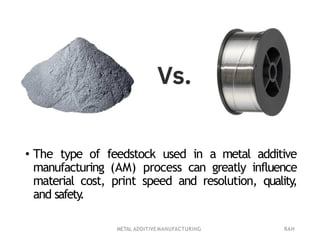

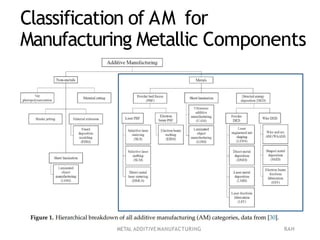

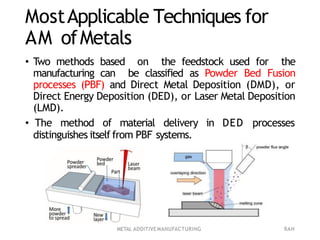

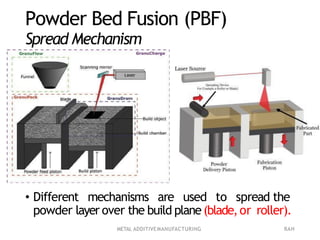

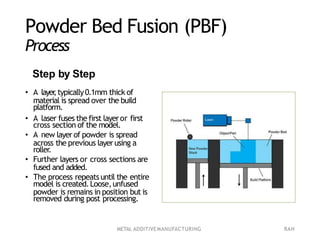

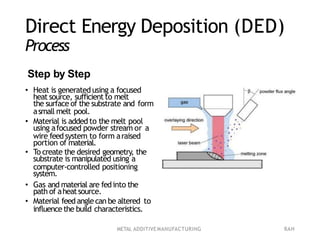

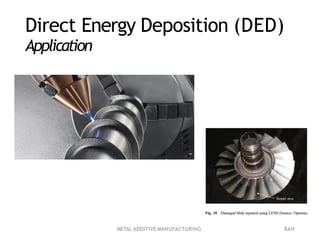

The lecture discusses additive manufacturing techniques for metals and superalloys, highlighting the advantages such as reduced waste and control of microstructures. It categorizes various metal additive manufacturing technologies, focusing on powder bed fusion (PBF) and direct energy deposition (DED), essential for applications in the aerospace industry. The document details the processes, advantages, and specific applications of these techniques, including component creation and repair methods.