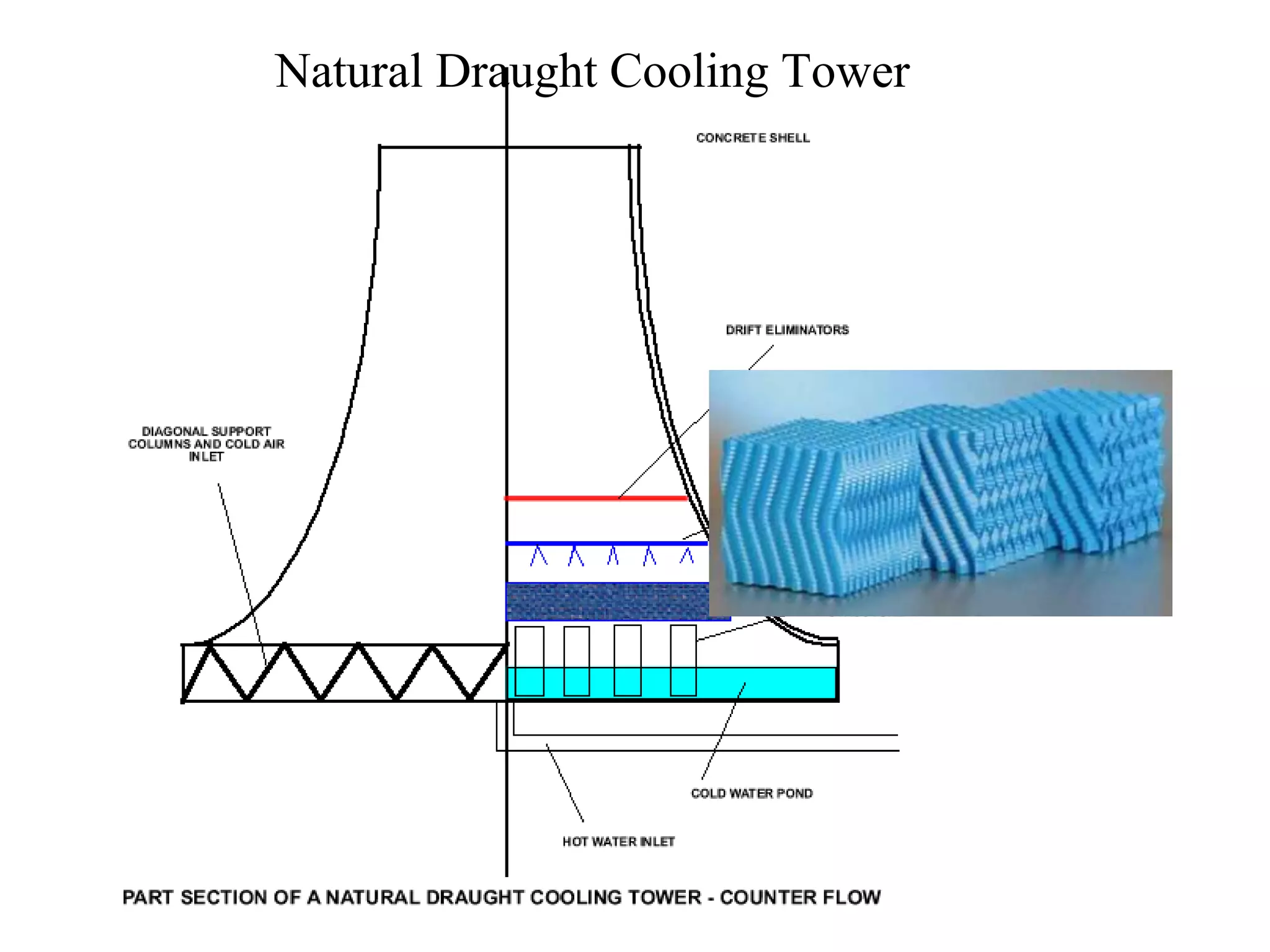

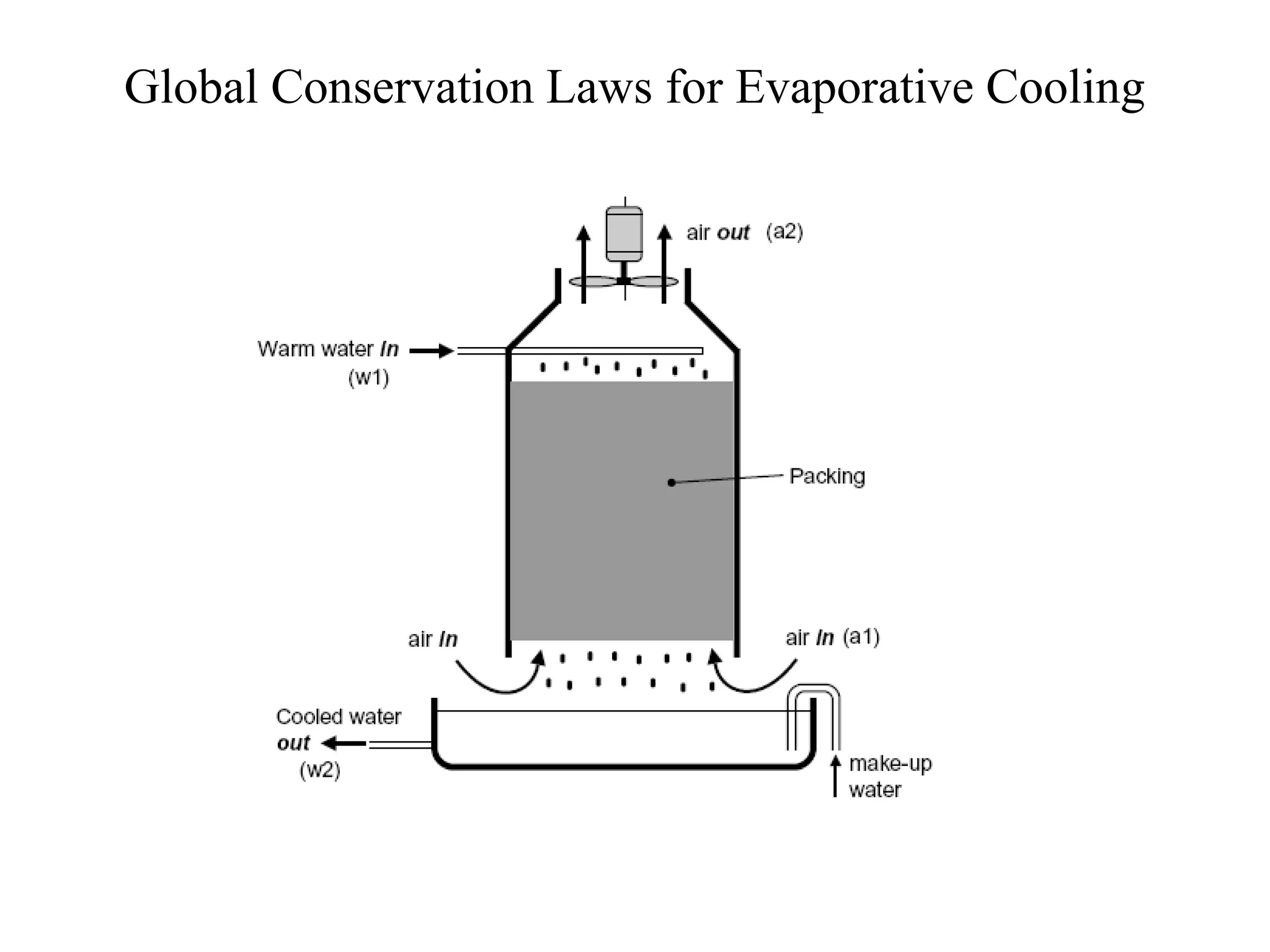

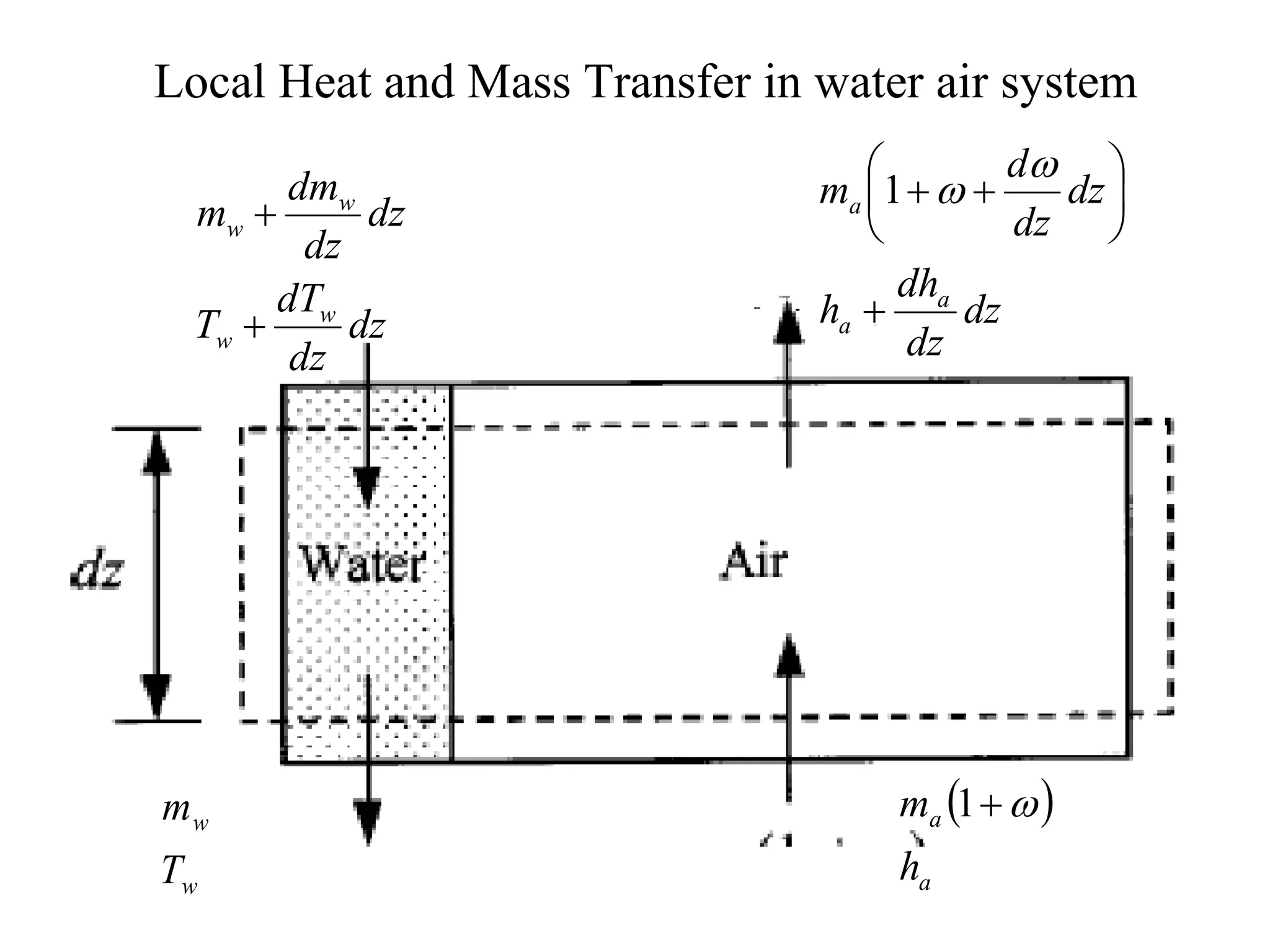

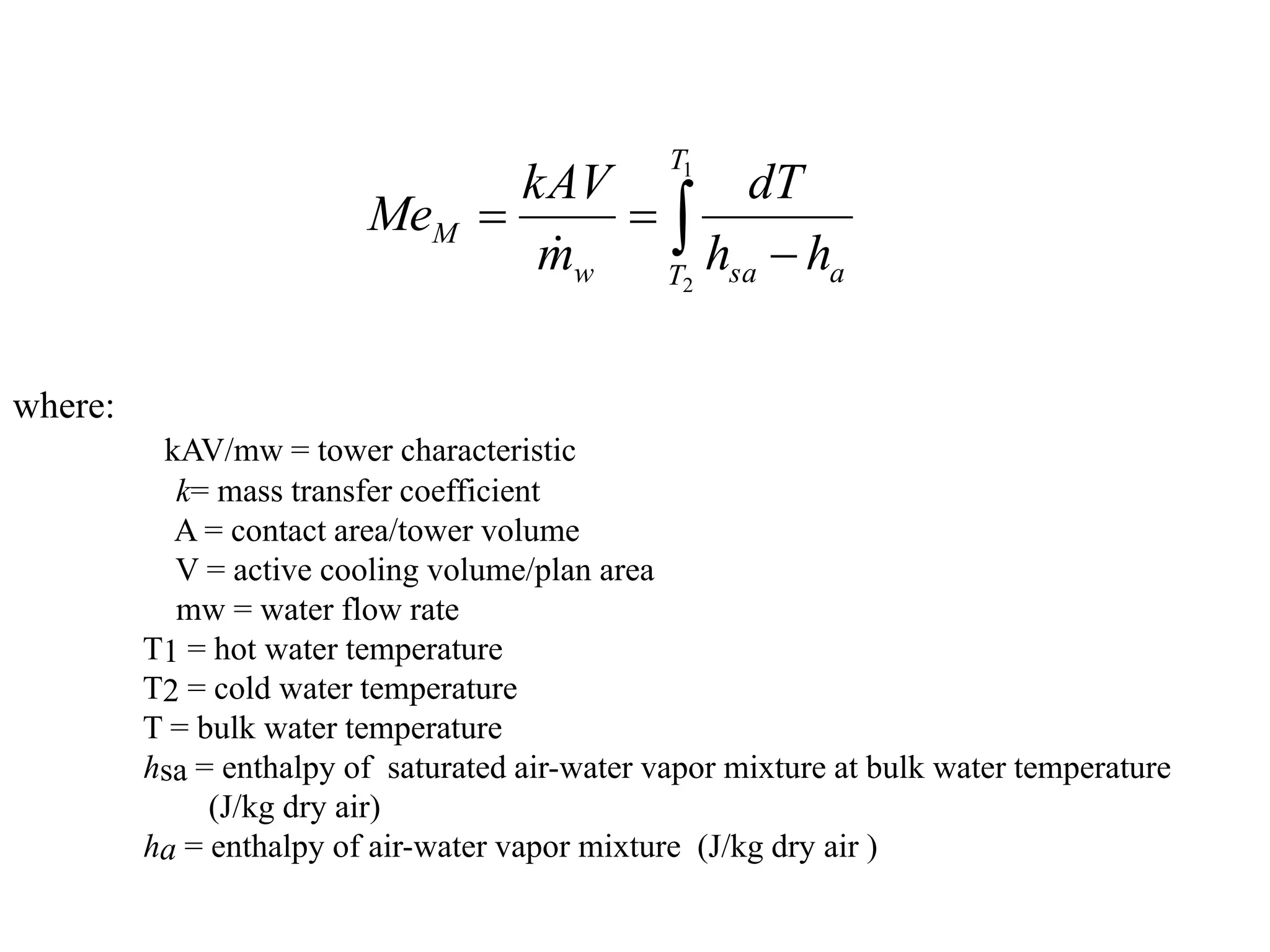

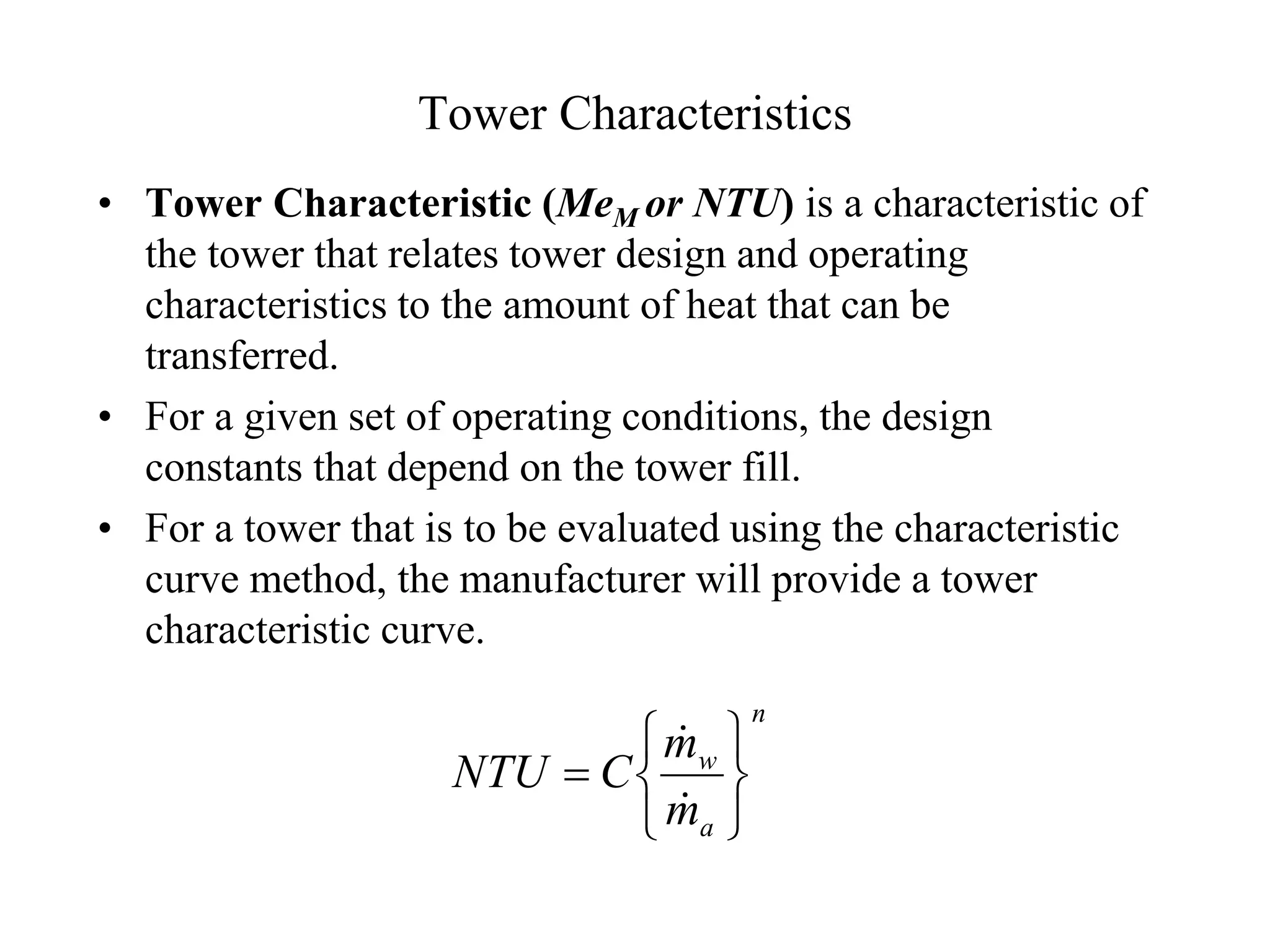

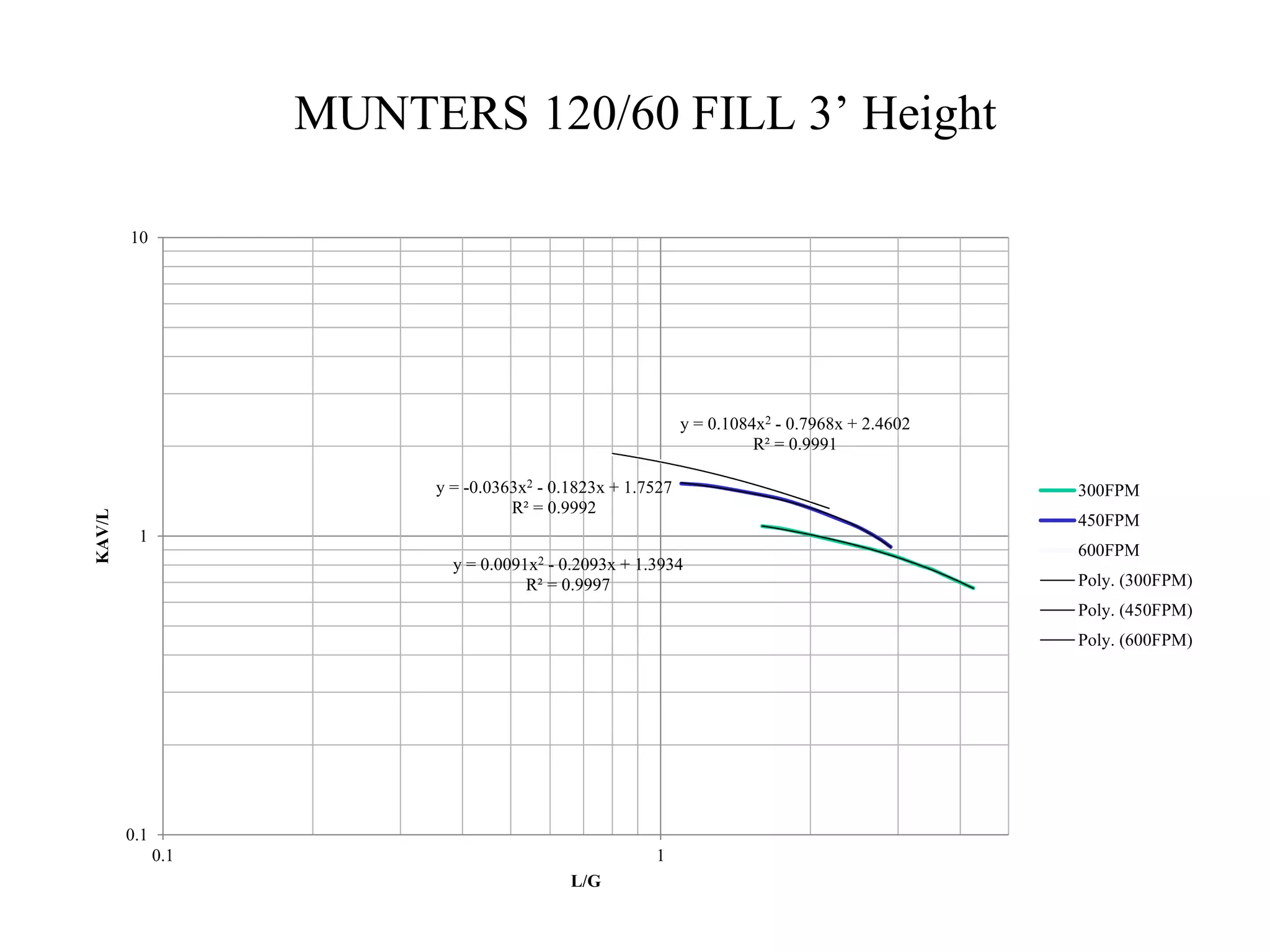

This document discusses the design and analysis of cooling towers. It begins with a brief history of cooling tower design and the development of theories to analyze them. It then discusses key parameters that describe cooling tower performance such as range, approach, and water/air ratio. The document outlines methods for analyzing cooling tower performance, including the Merkel method and global conservation equations. It also discusses factors that affect heat transfer in cooling towers and how tower characteristics are determined. Finally, it covers other important design considerations like pressure drops, fan power requirements, and water losses through evaporation and drift.