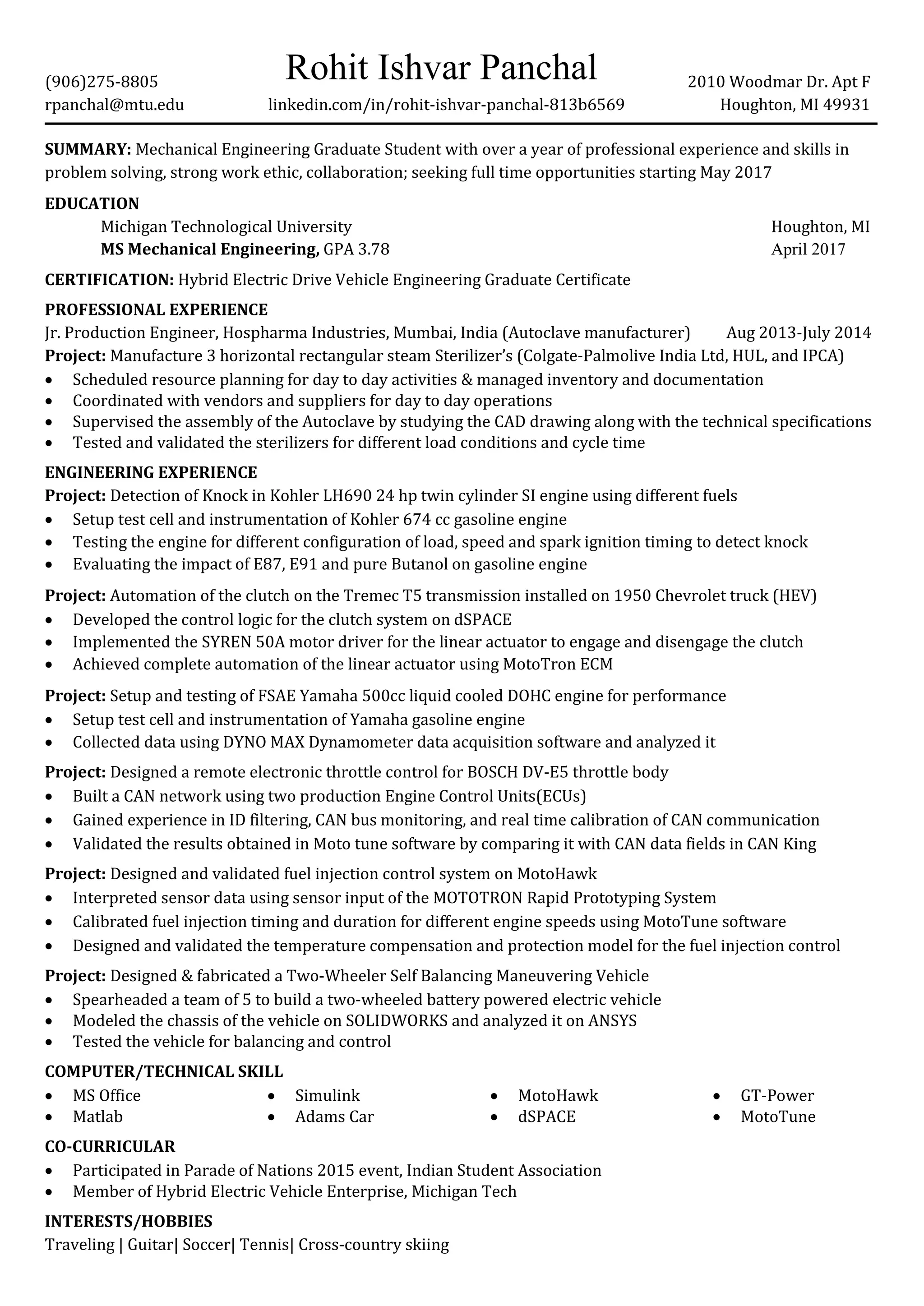

Rohit Ishvar Panchal is seeking full-time mechanical engineering opportunities starting in May 2017. He has a MS in Mechanical Engineering from Michigan Technological University with a 3.78 GPA. He has over a year of experience as a production engineer in India and has worked on several engineering projects involving engines, transmissions, and vehicles while in graduate school.