Embed presentation

Download to read offline

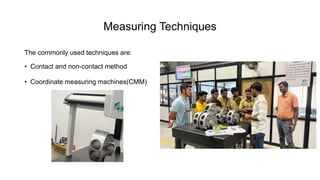

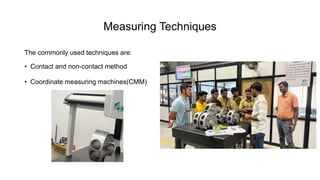

The document discusses measurement techniques like contact and non-contact methods and coordinate measuring machines used to ensure symmetry in manufacturing. Symmetry is important for automotive, aerospace, and electronics industries as well as tools and machinery. Maintaining symmetry is critical to ensure product performance and safety as well as serve as a quality control measure to detect defects according to specifications.