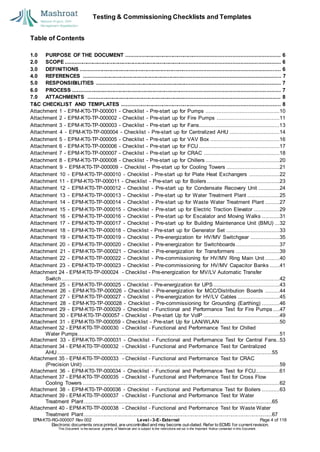

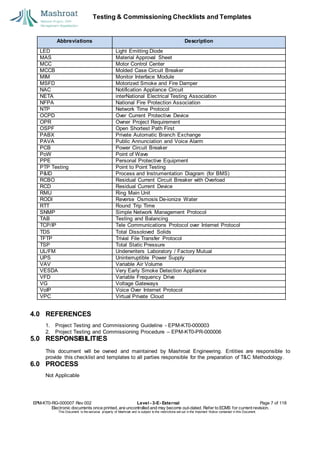

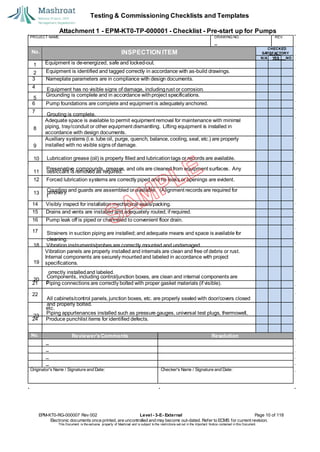

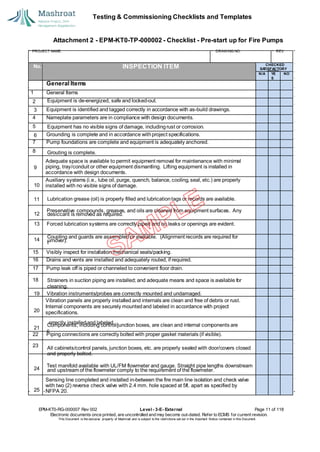

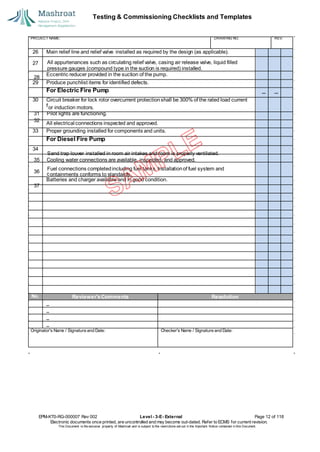

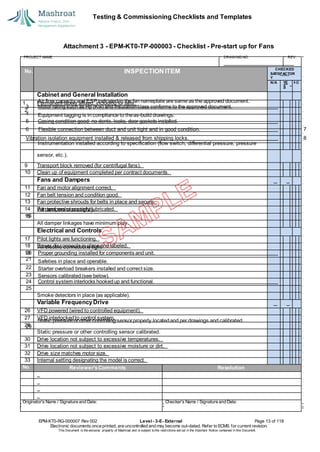

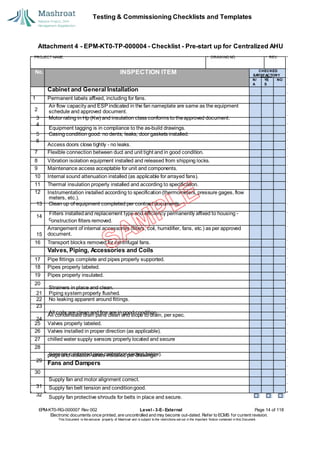

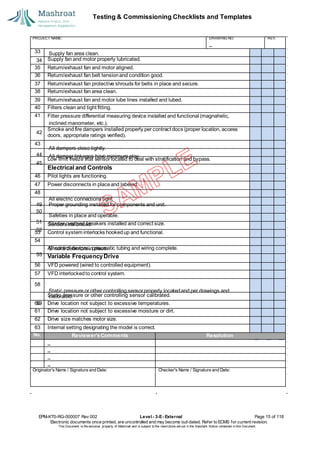

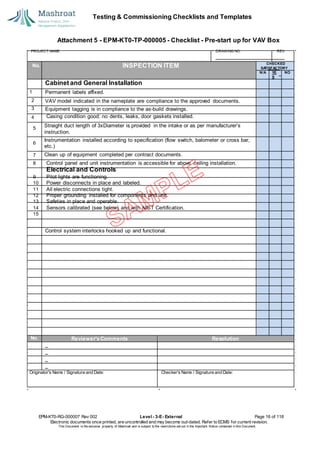

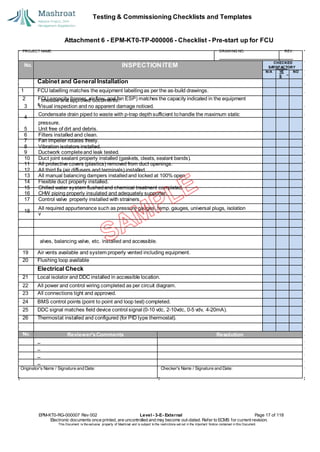

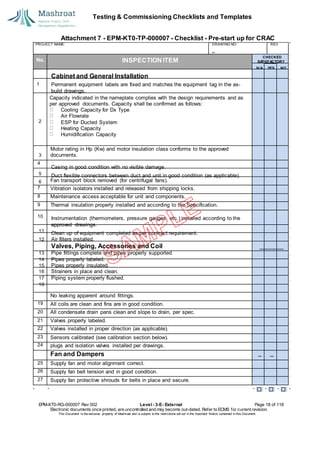

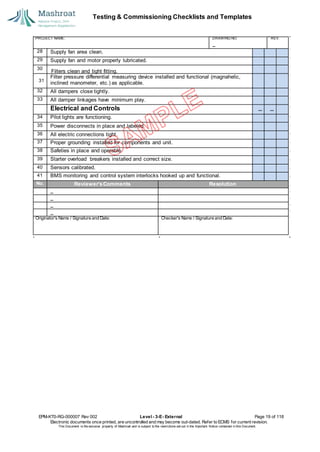

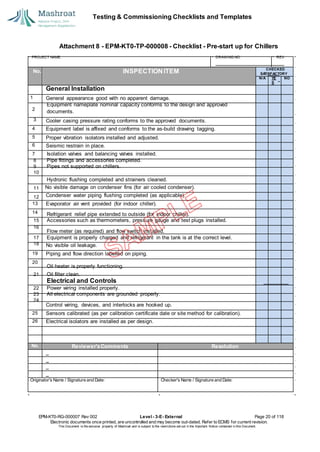

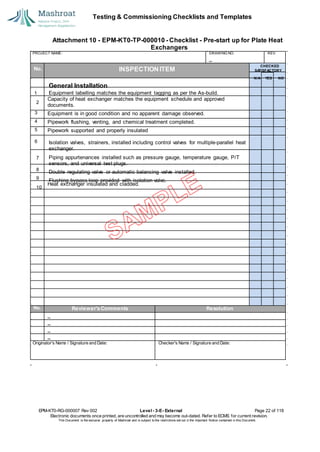

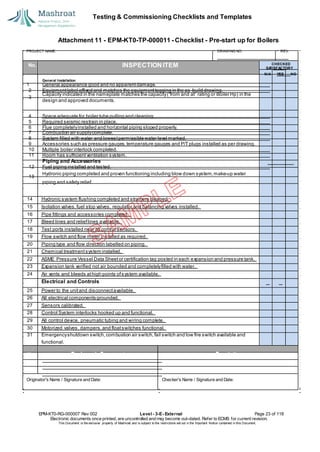

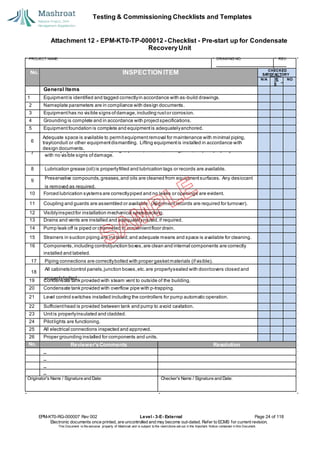

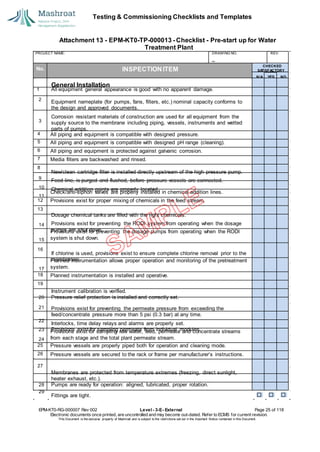

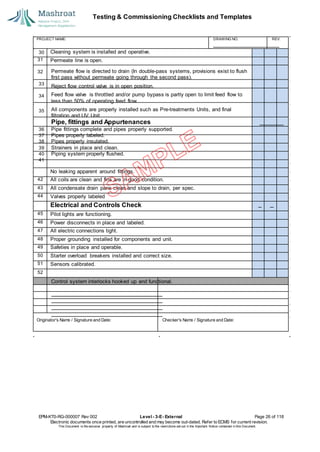

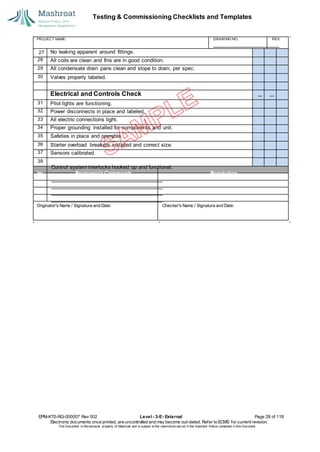

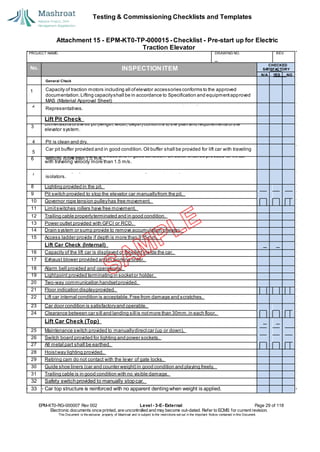

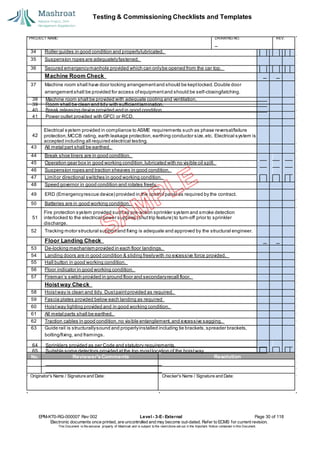

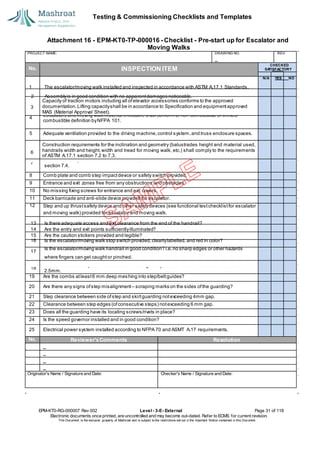

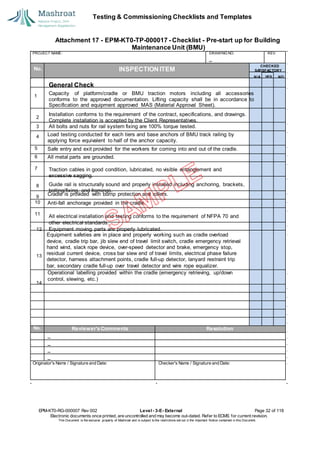

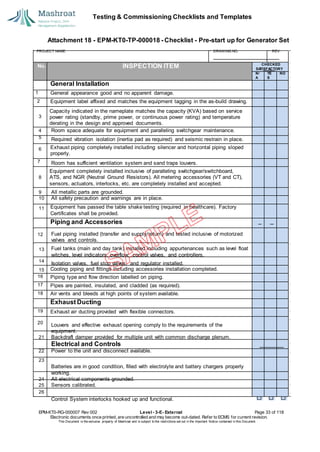

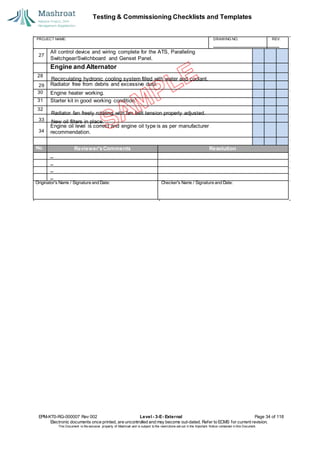

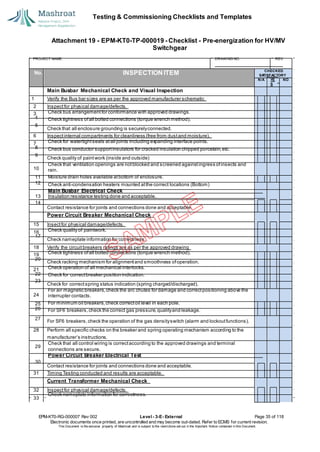

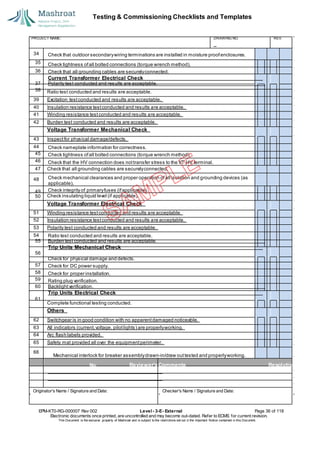

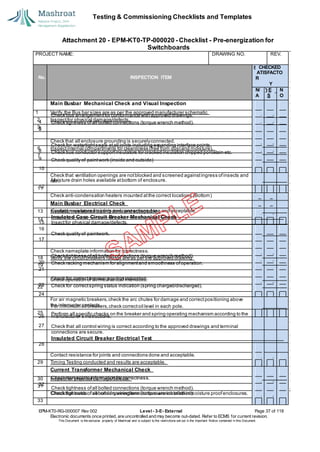

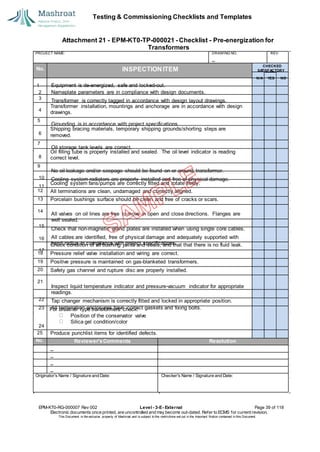

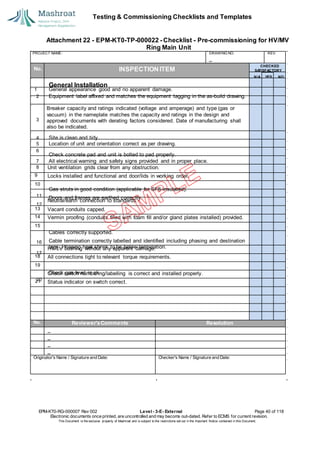

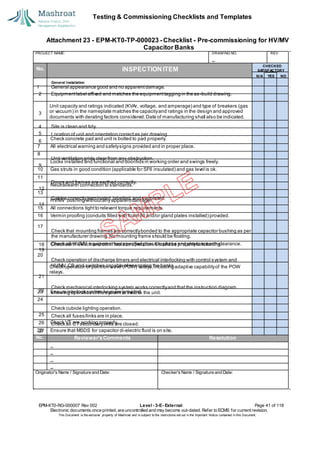

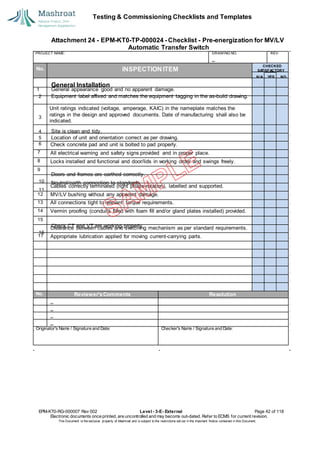

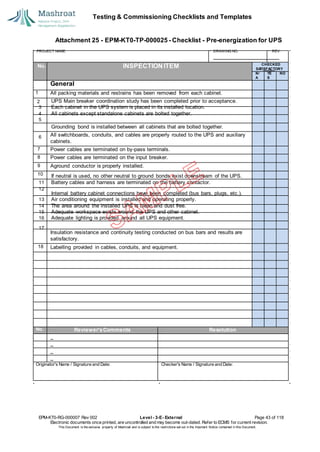

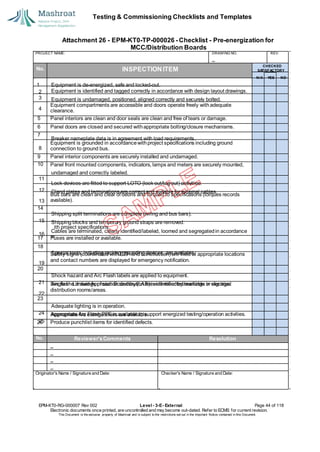

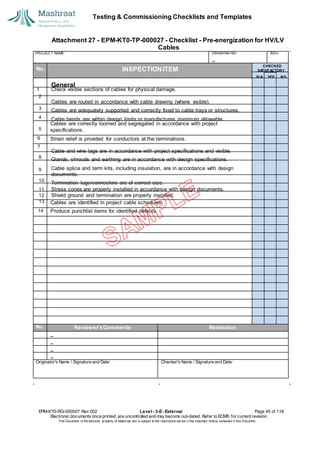

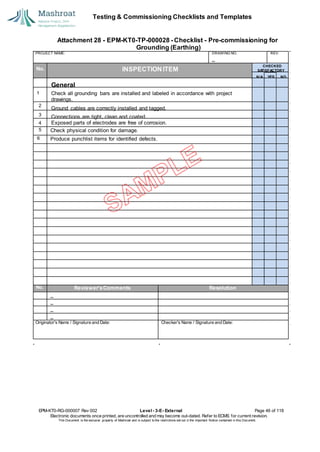

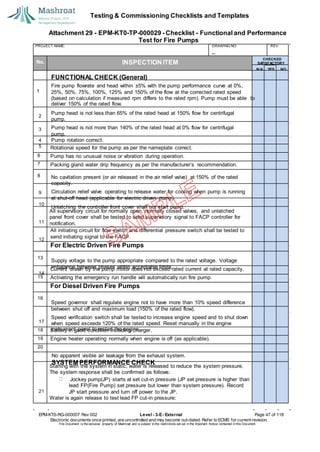

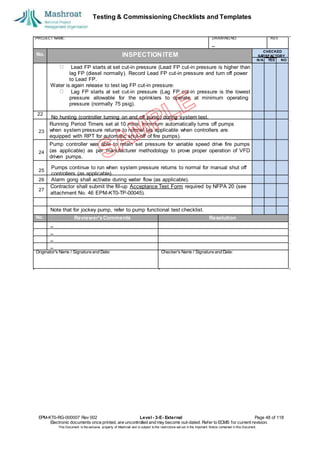

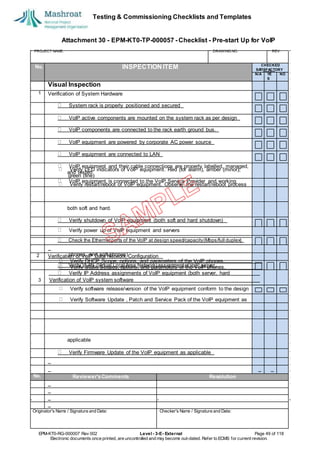

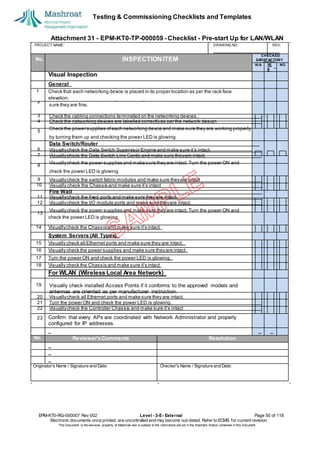

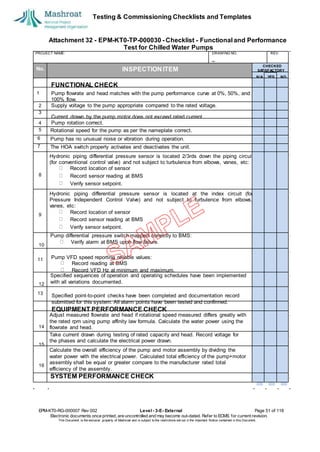

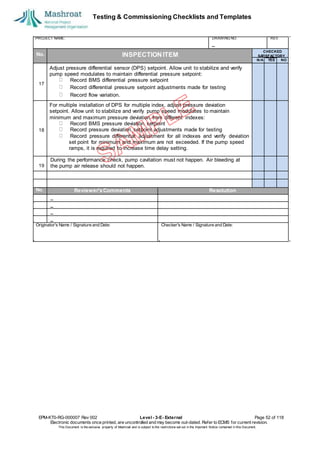

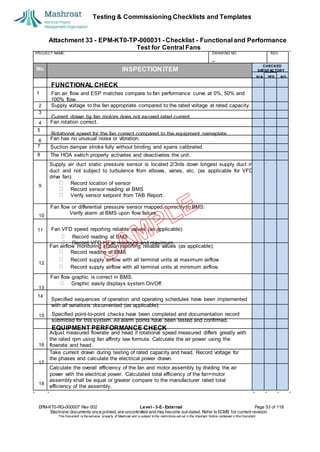

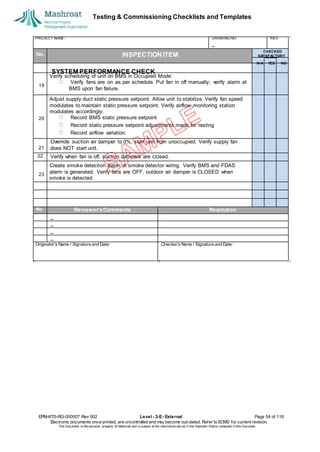

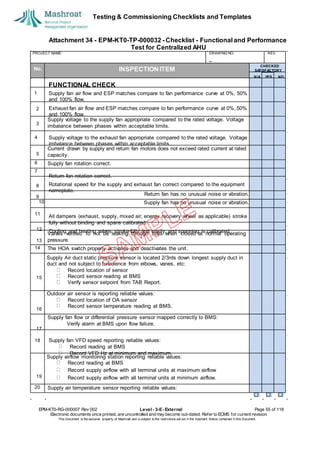

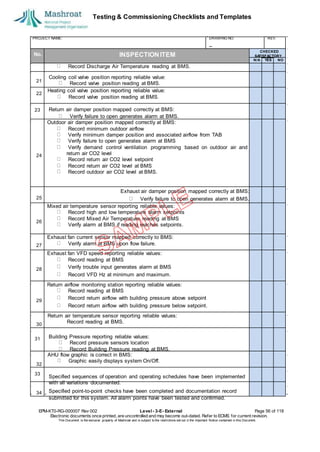

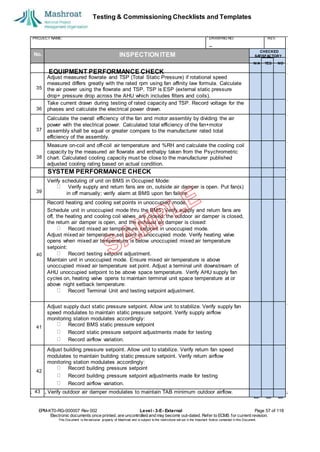

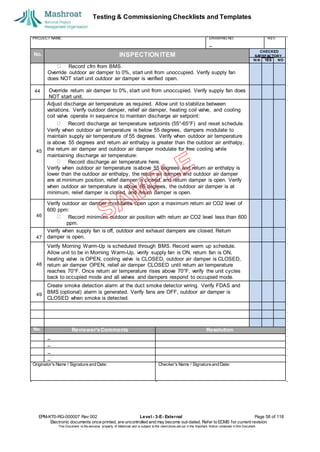

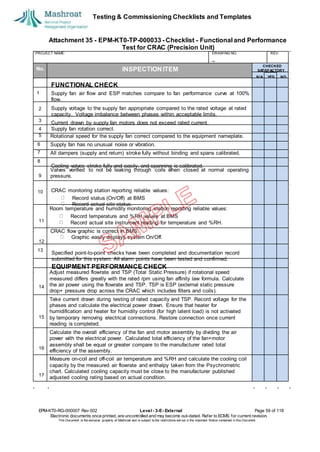

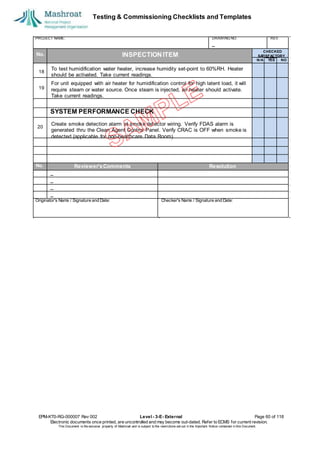

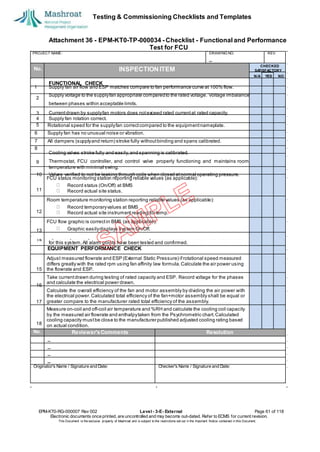

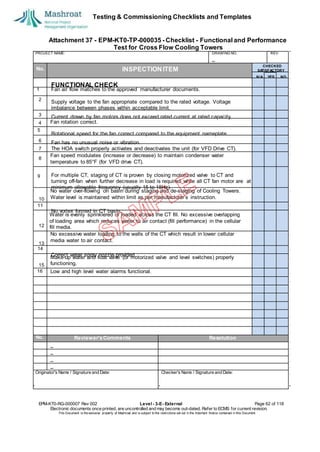

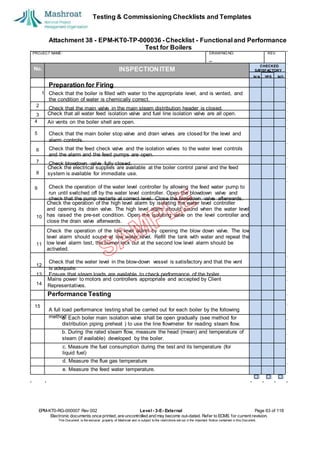

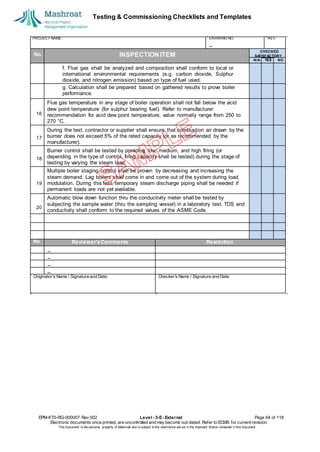

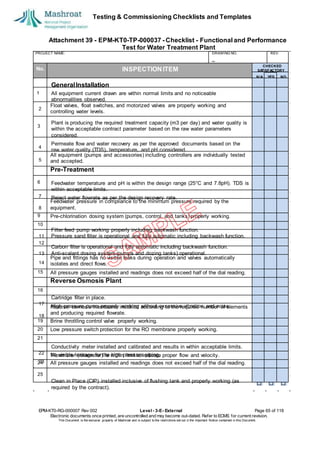

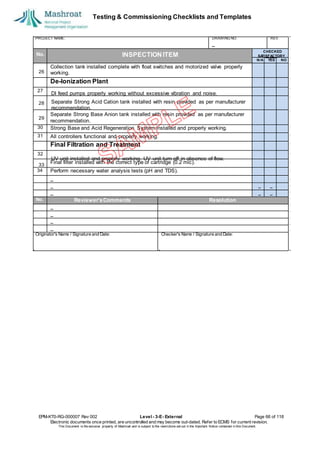

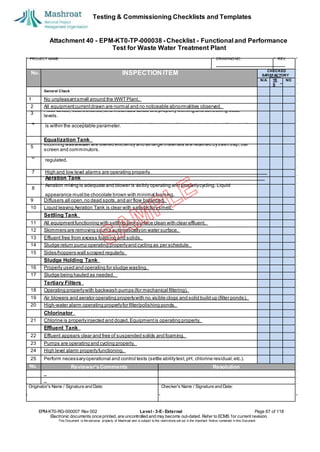

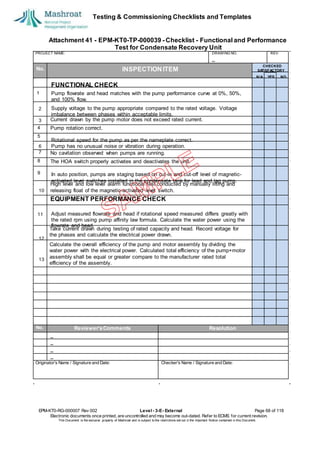

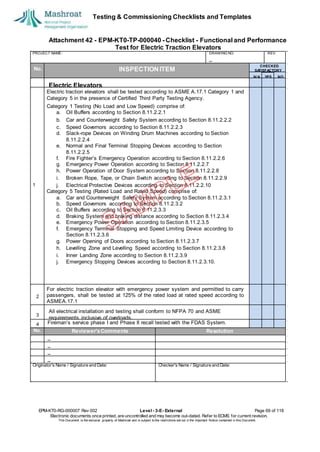

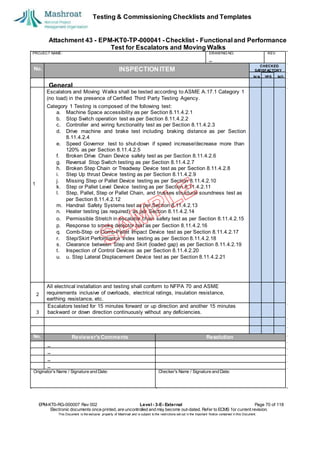

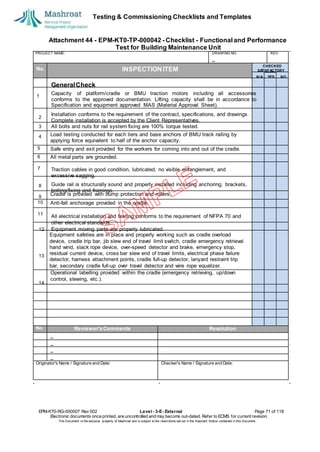

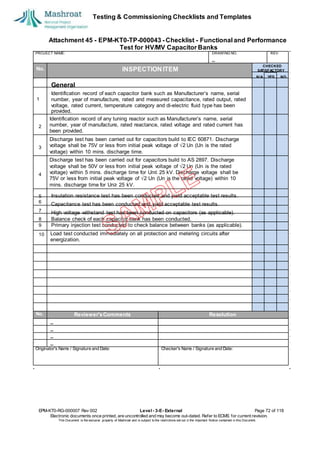

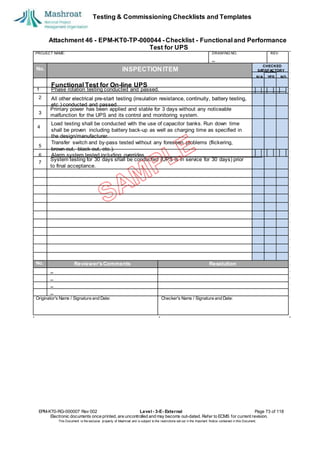

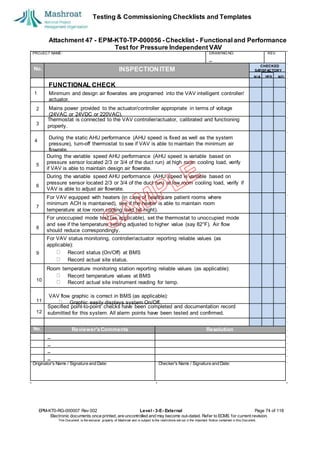

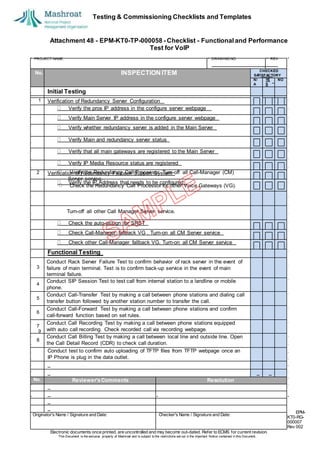

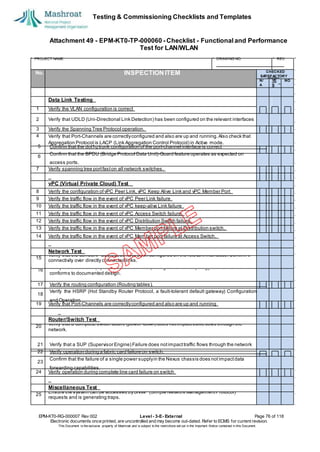

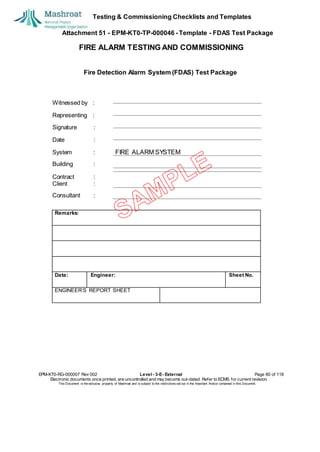

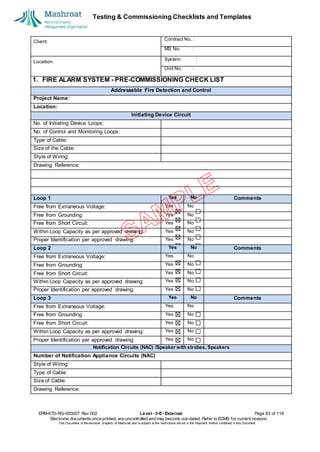

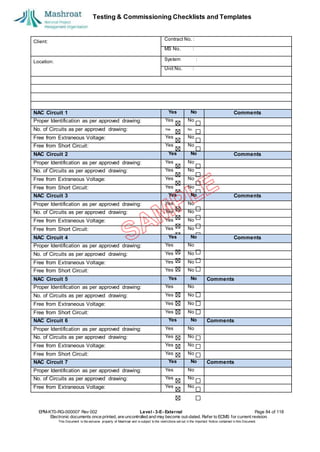

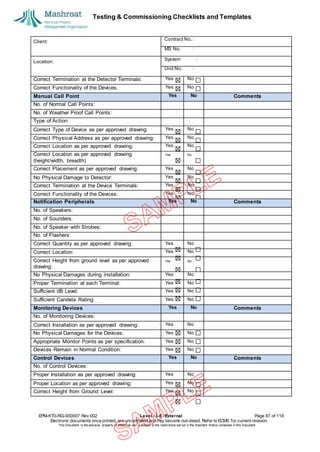

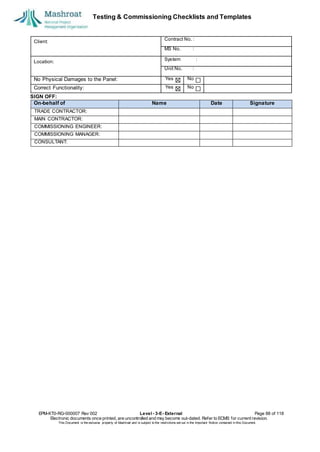

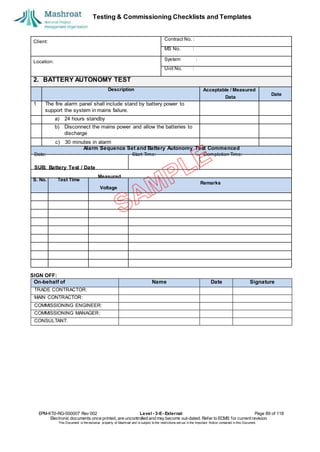

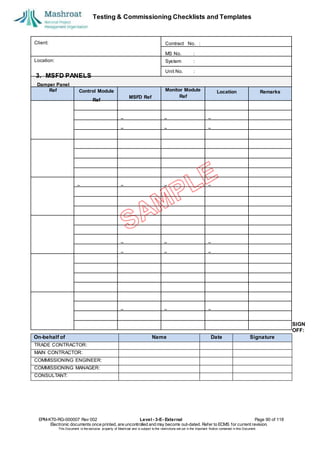

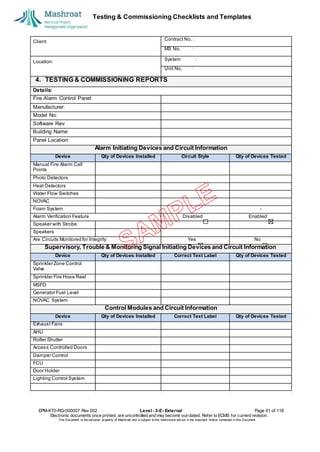

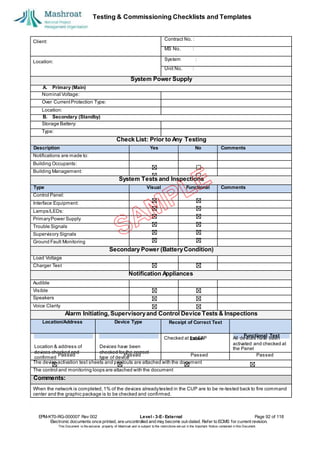

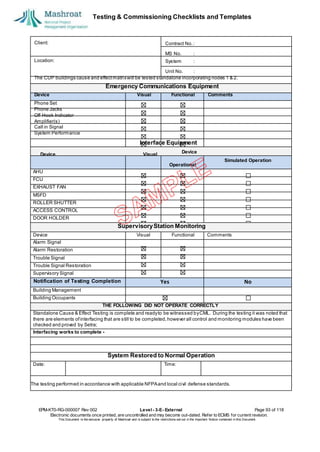

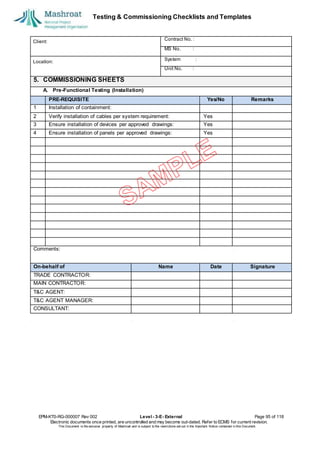

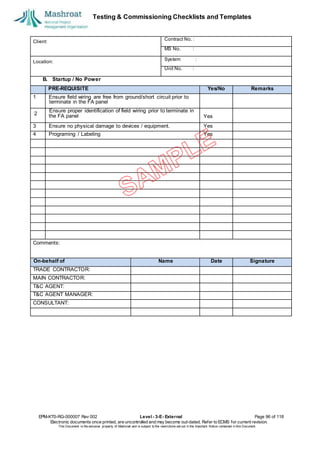

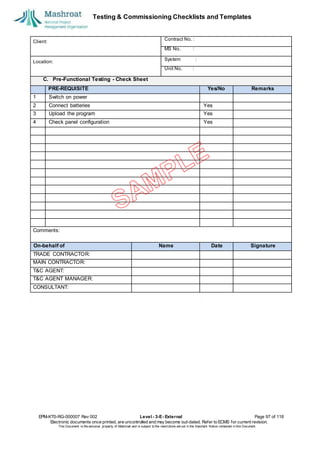

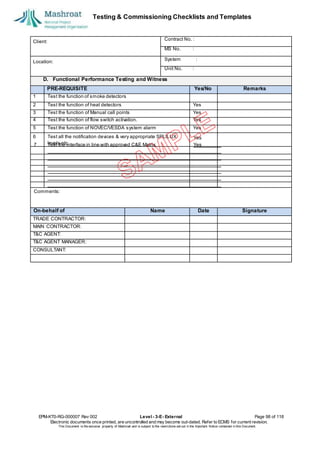

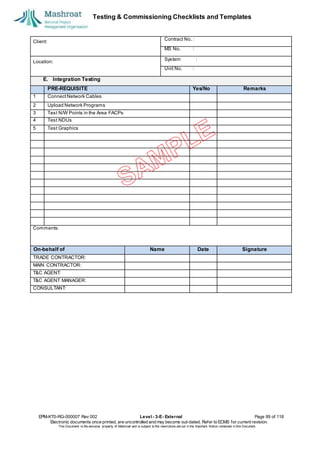

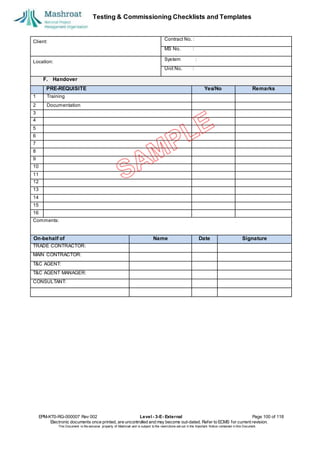

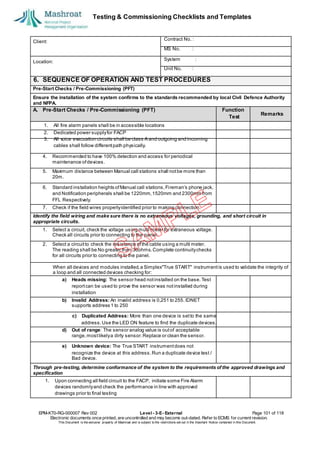

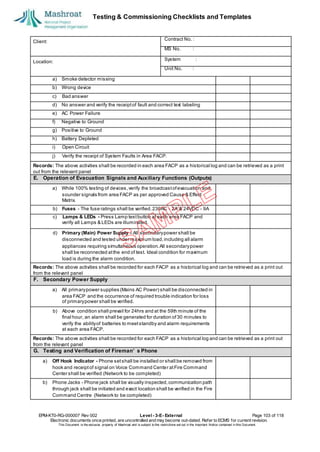

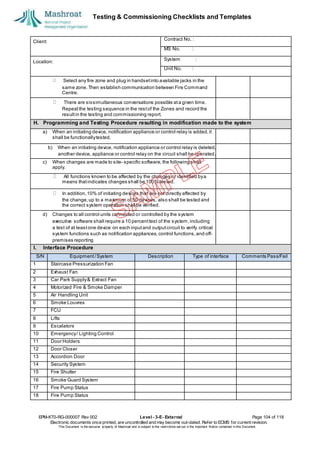

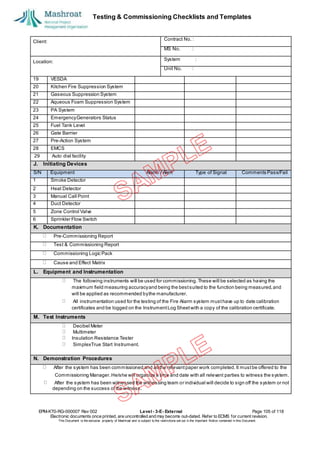

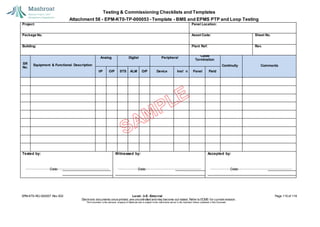

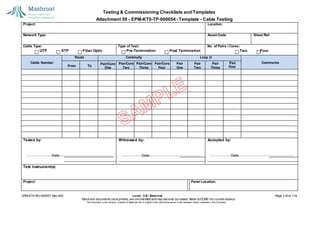

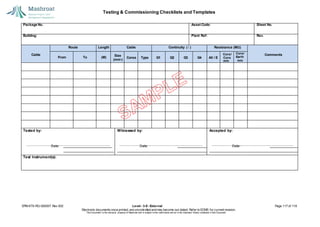

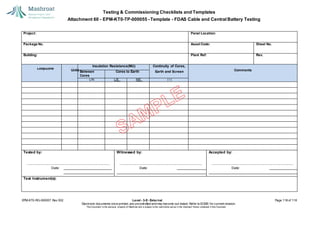

This document provides testing and commissioning checklists and templates to support the project testing and commissioning guideline and procedure. It includes 60 attachments that provide sample pre-commissioning and commissioning checklists for various mechanical, electrical, and plumbing equipment. The checklists and templates are to be used as a guide and tailored for each specific project. The document also defines various relevant abbreviations and references the project testing and commissioning guideline and procedure documents.