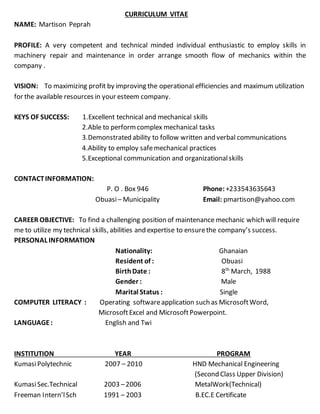

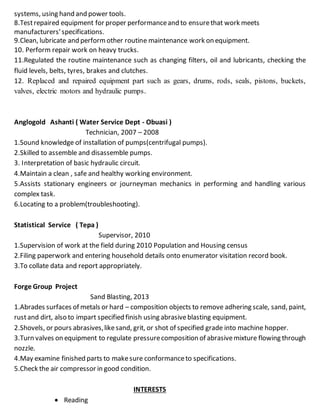

Martison Peprah is seeking a position as a maintenance mechanic. He has over 10 years of experience in machinery repair and maintenance for mining and construction equipment. His experience includes work with Sandvik, Caterpillar, Normet, and Anglogold Ashanti machines. He has strong technical skills in mechanical tasks, communication skills, and safety practices. He holds an HND in Mechanical Engineering and certificates in metal work and technical education.