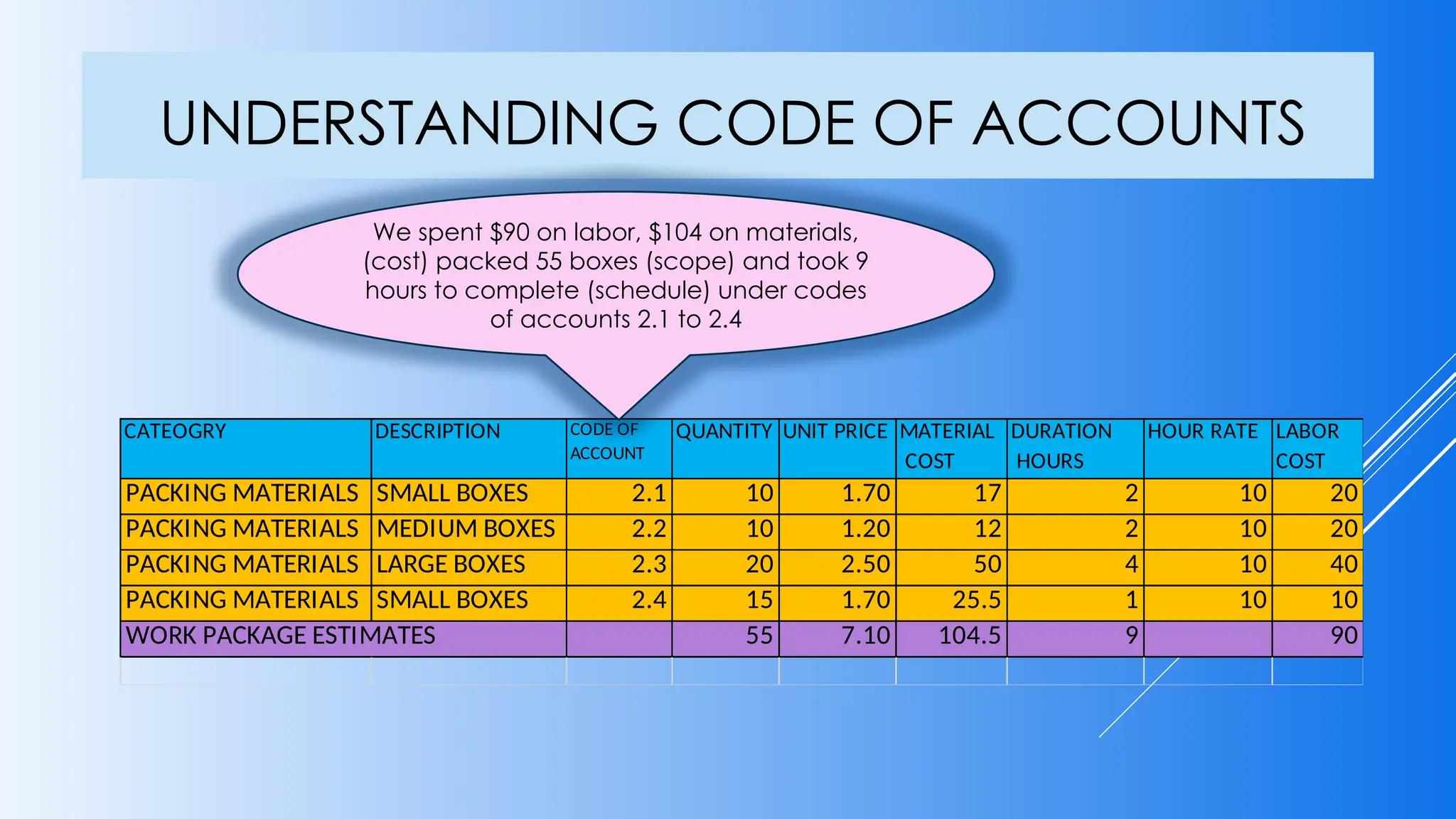

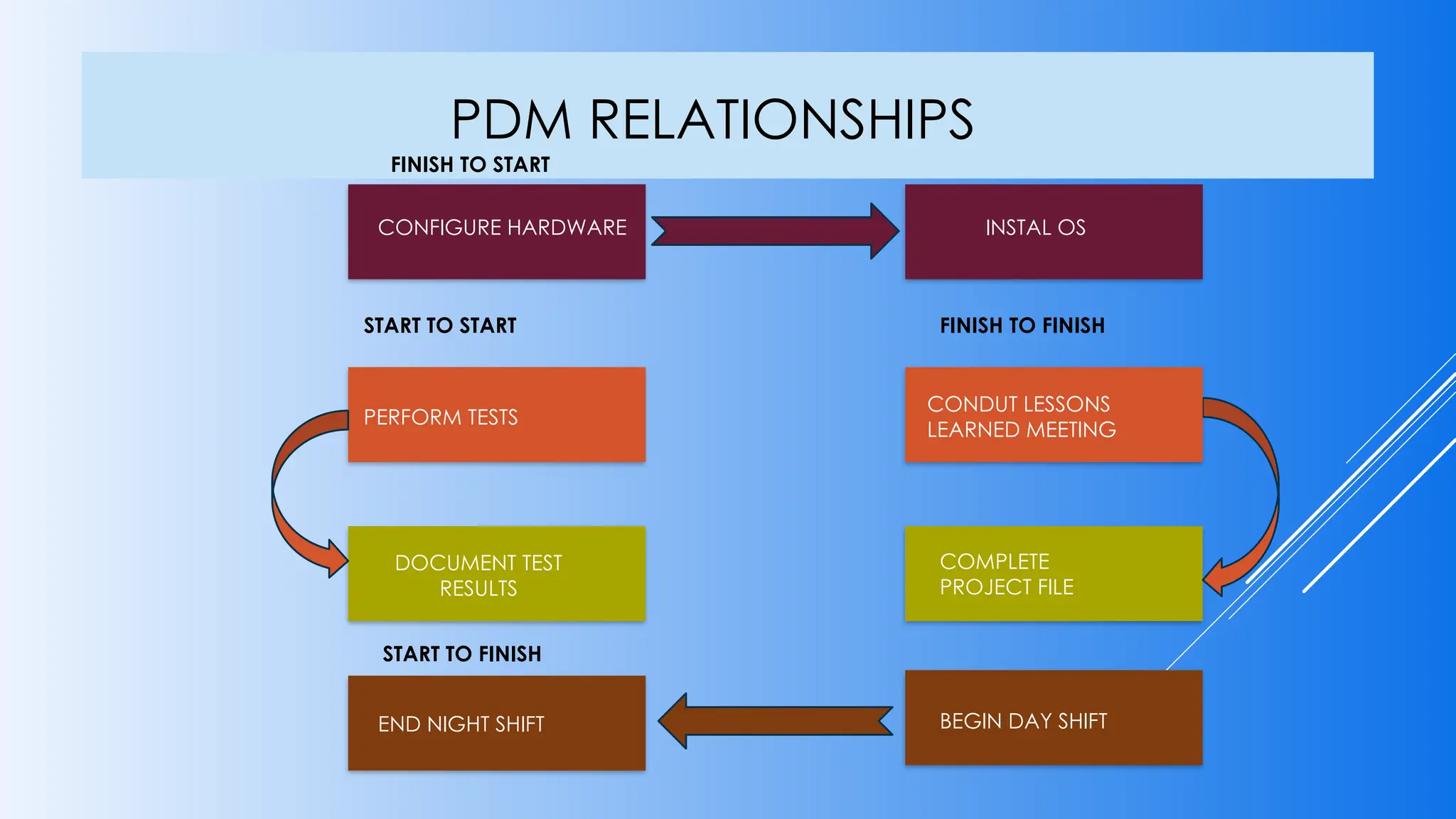

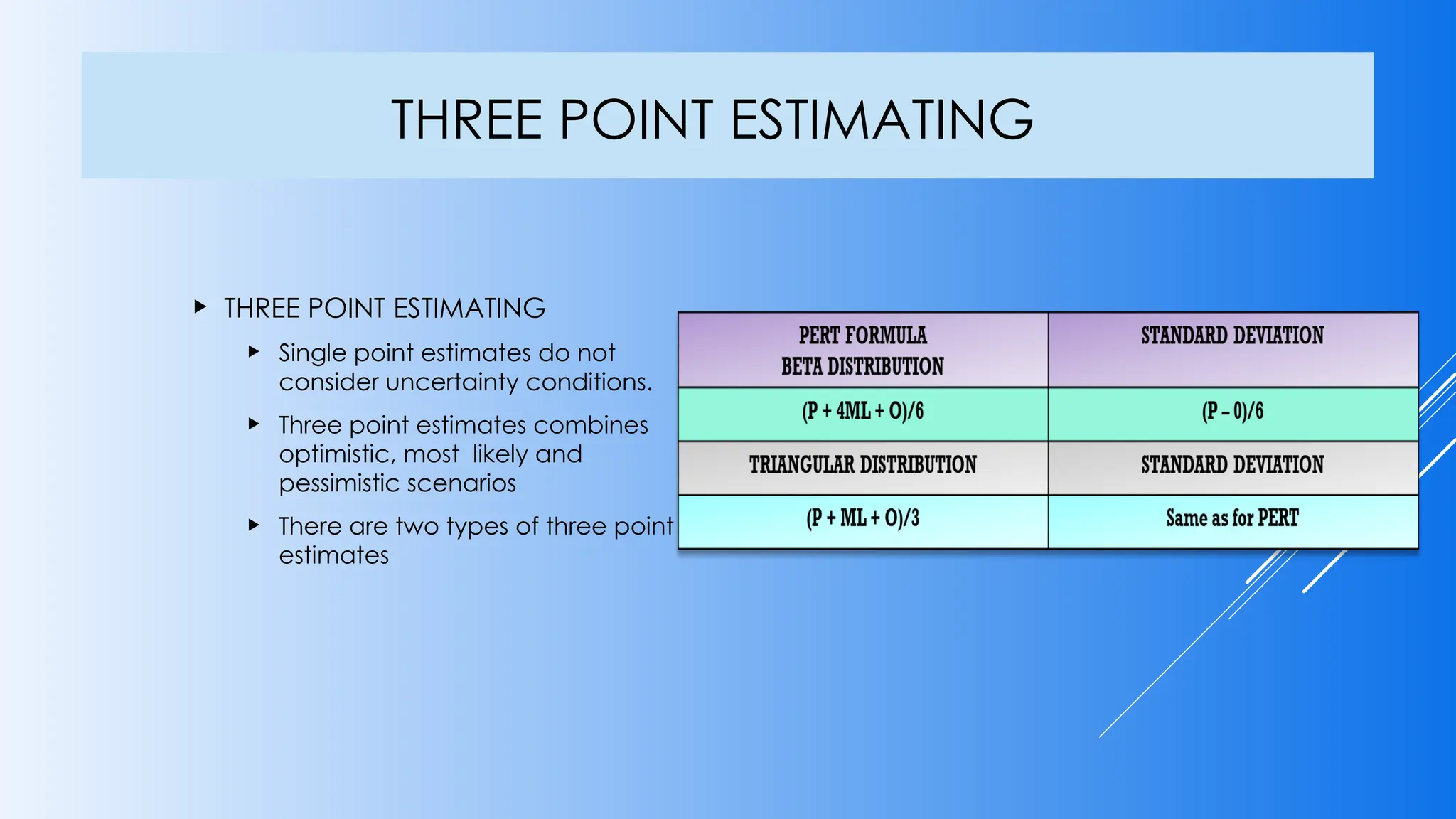

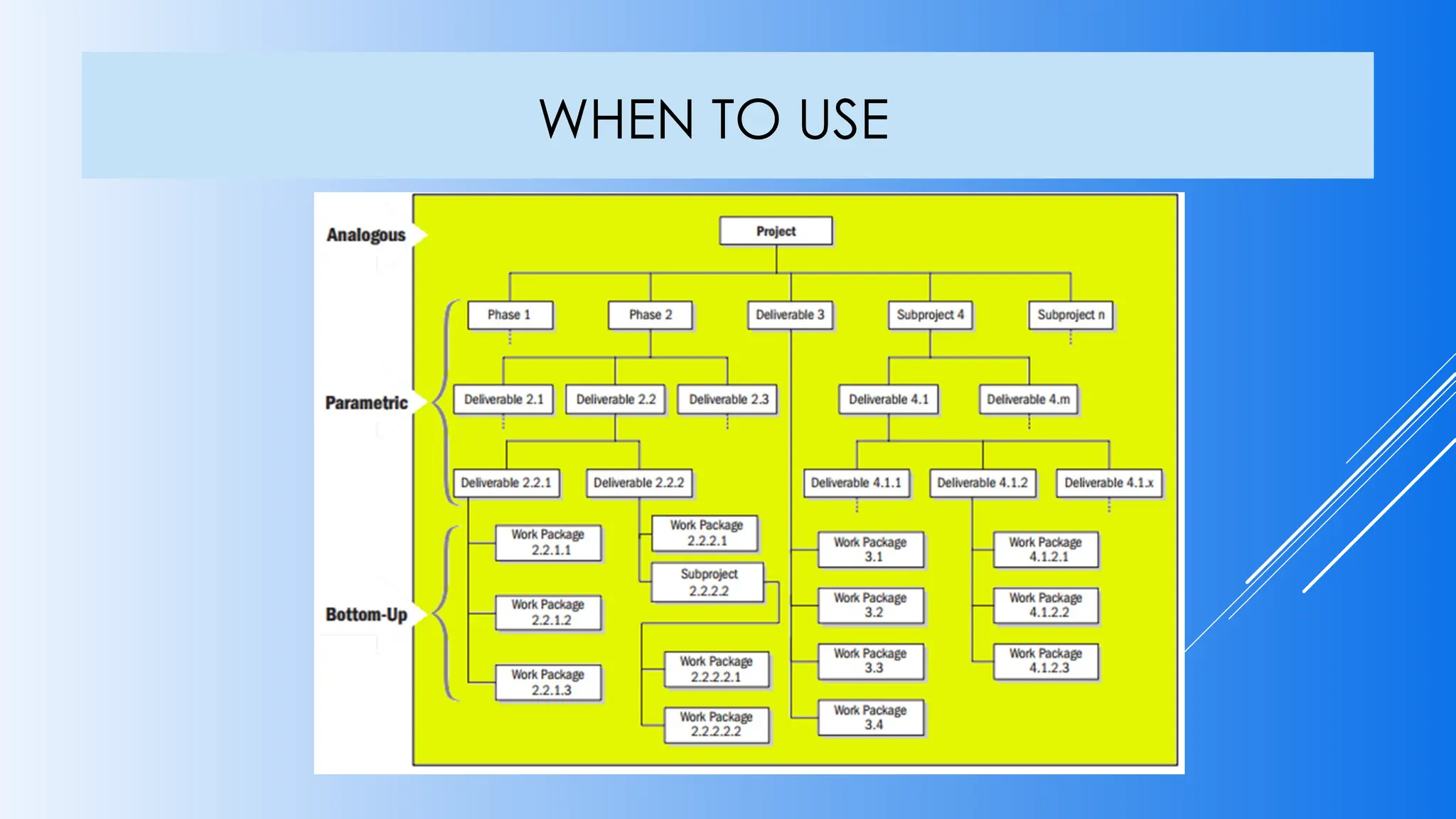

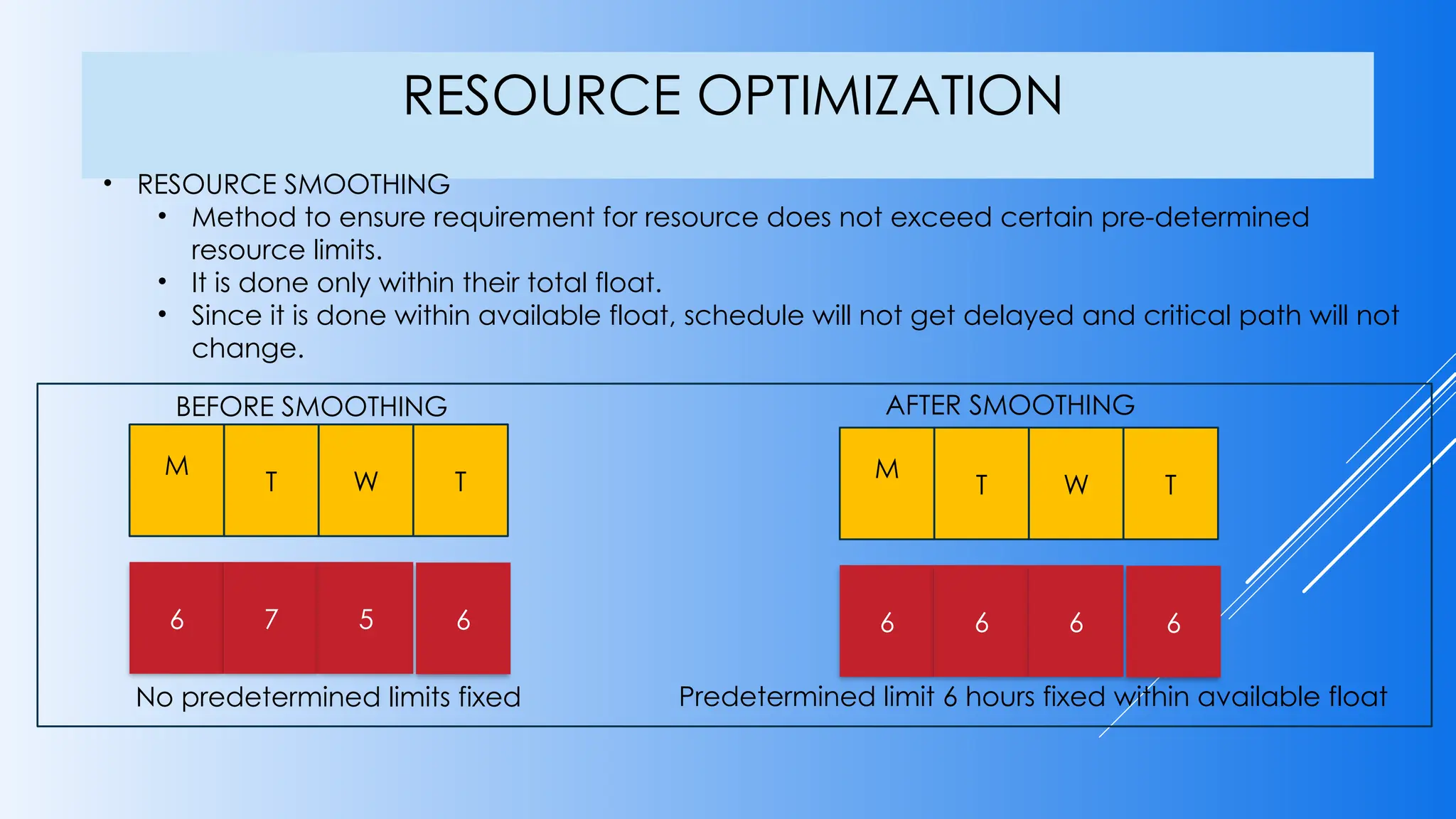

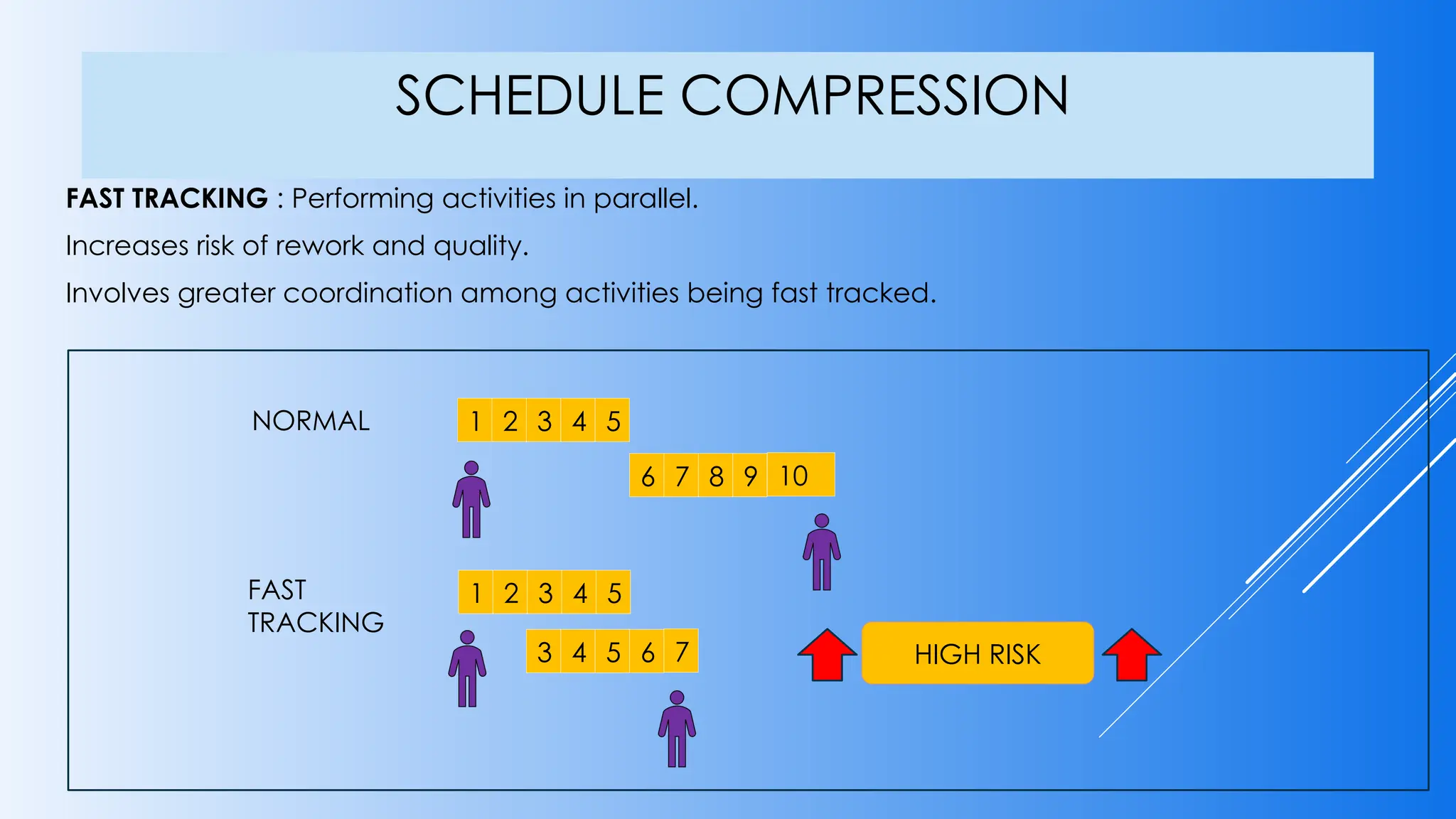

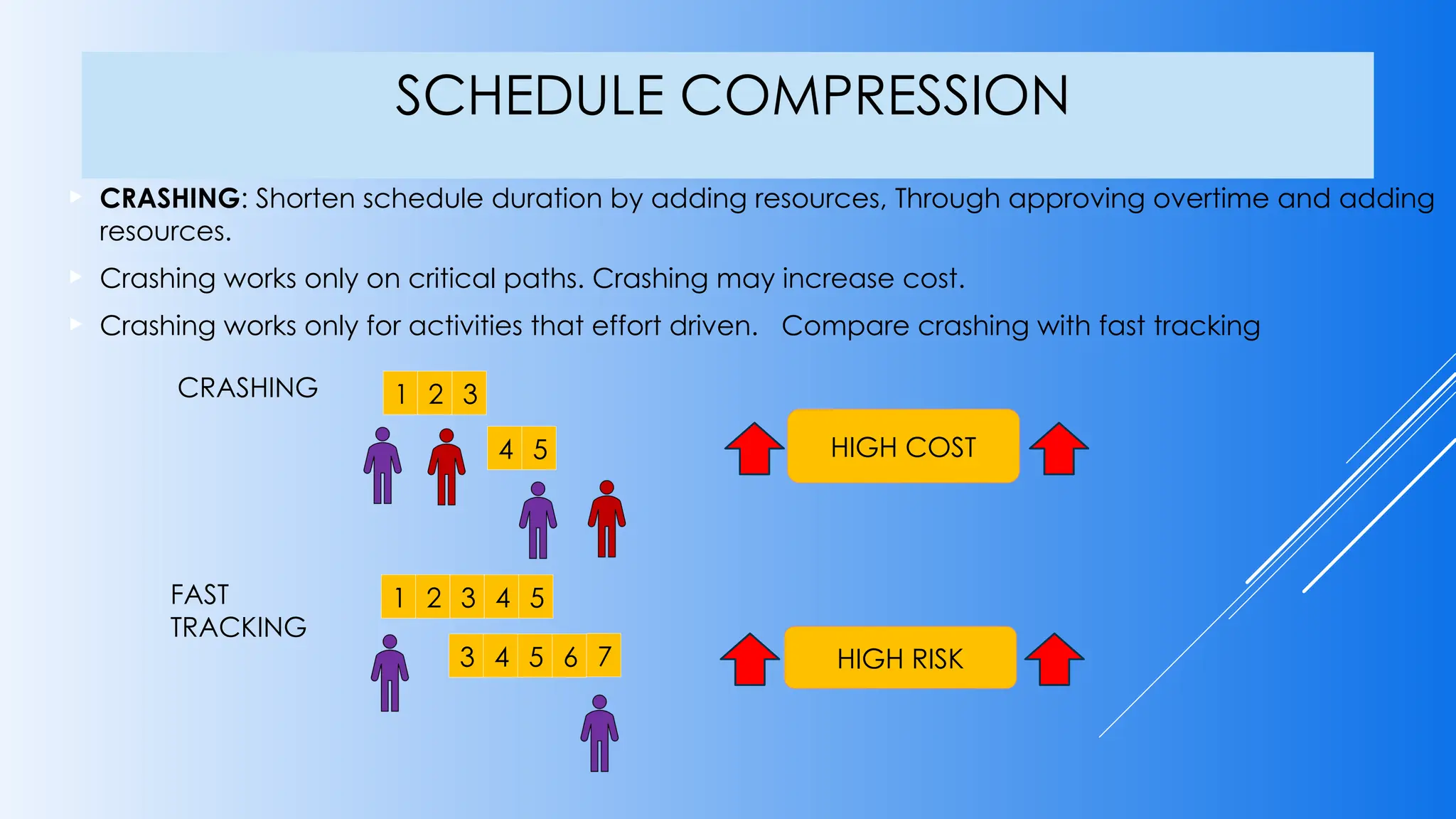

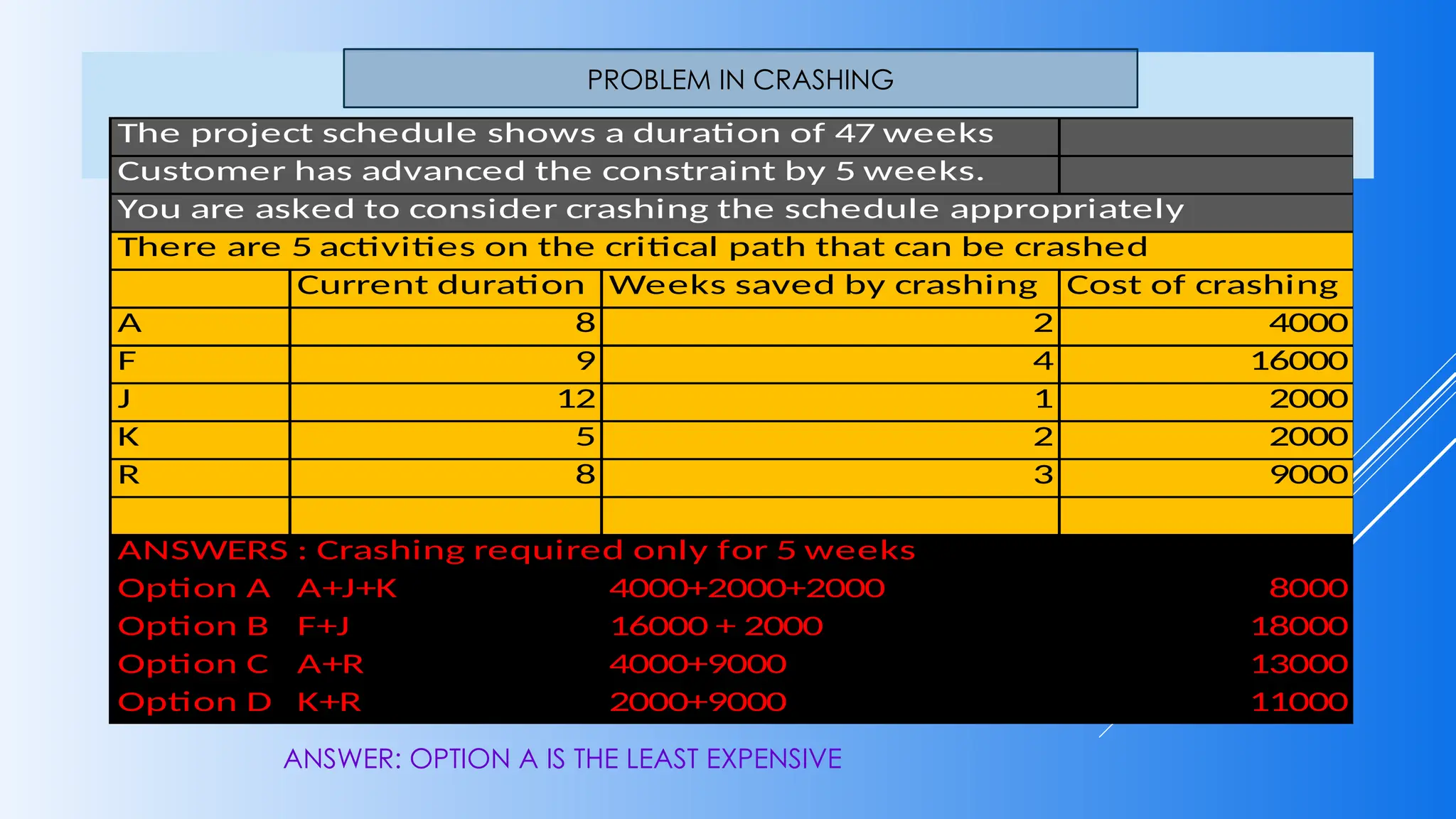

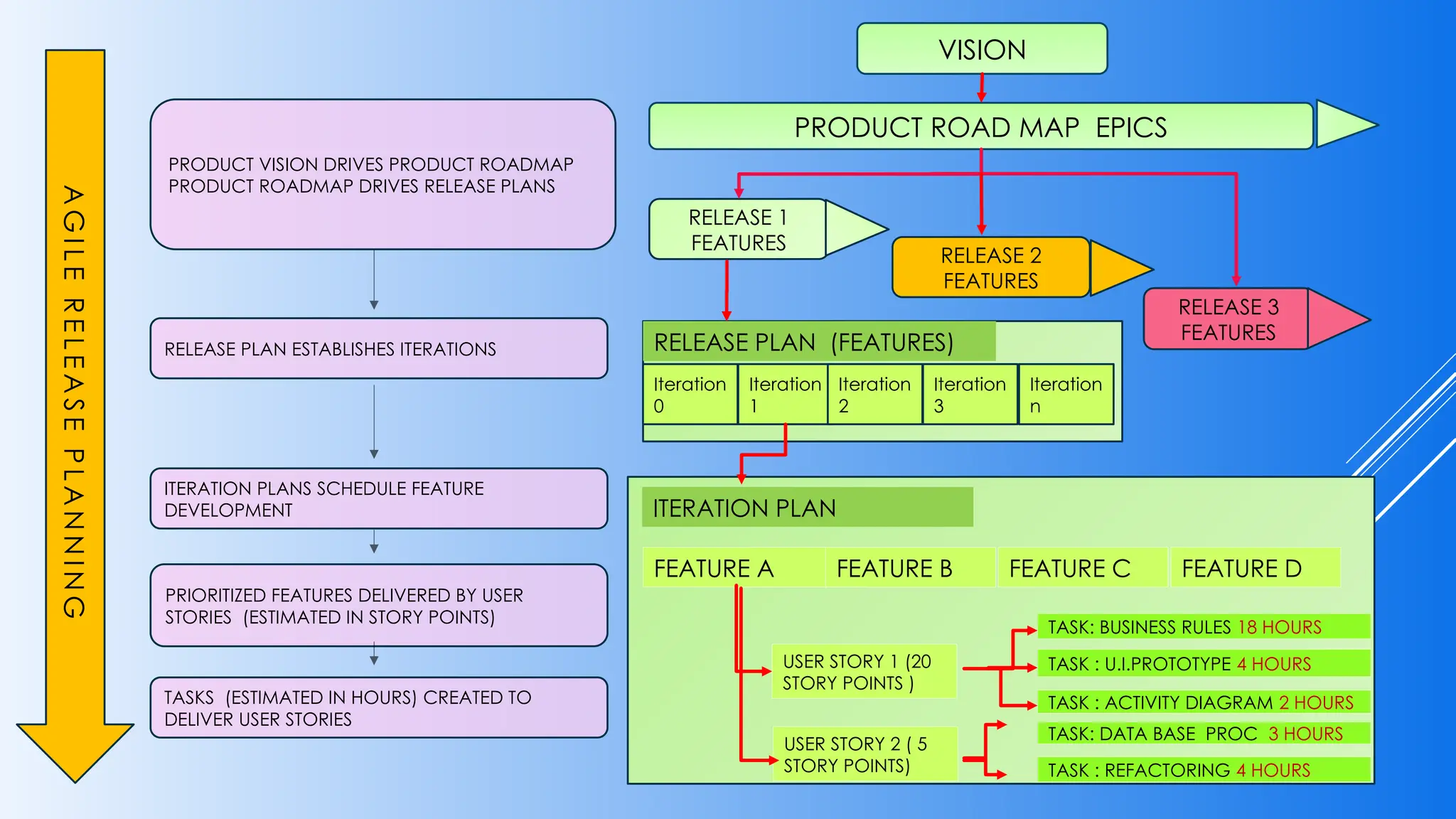

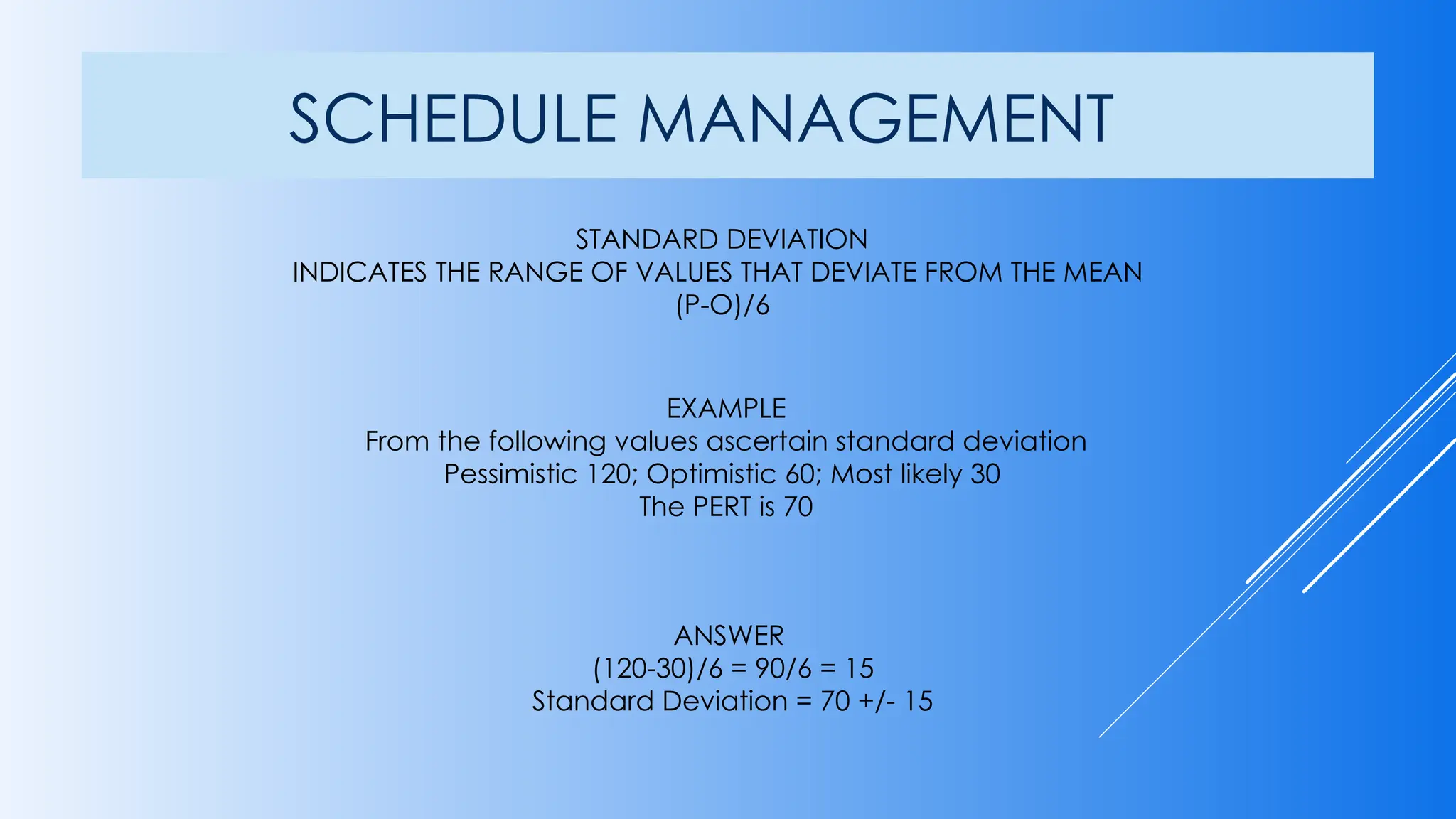

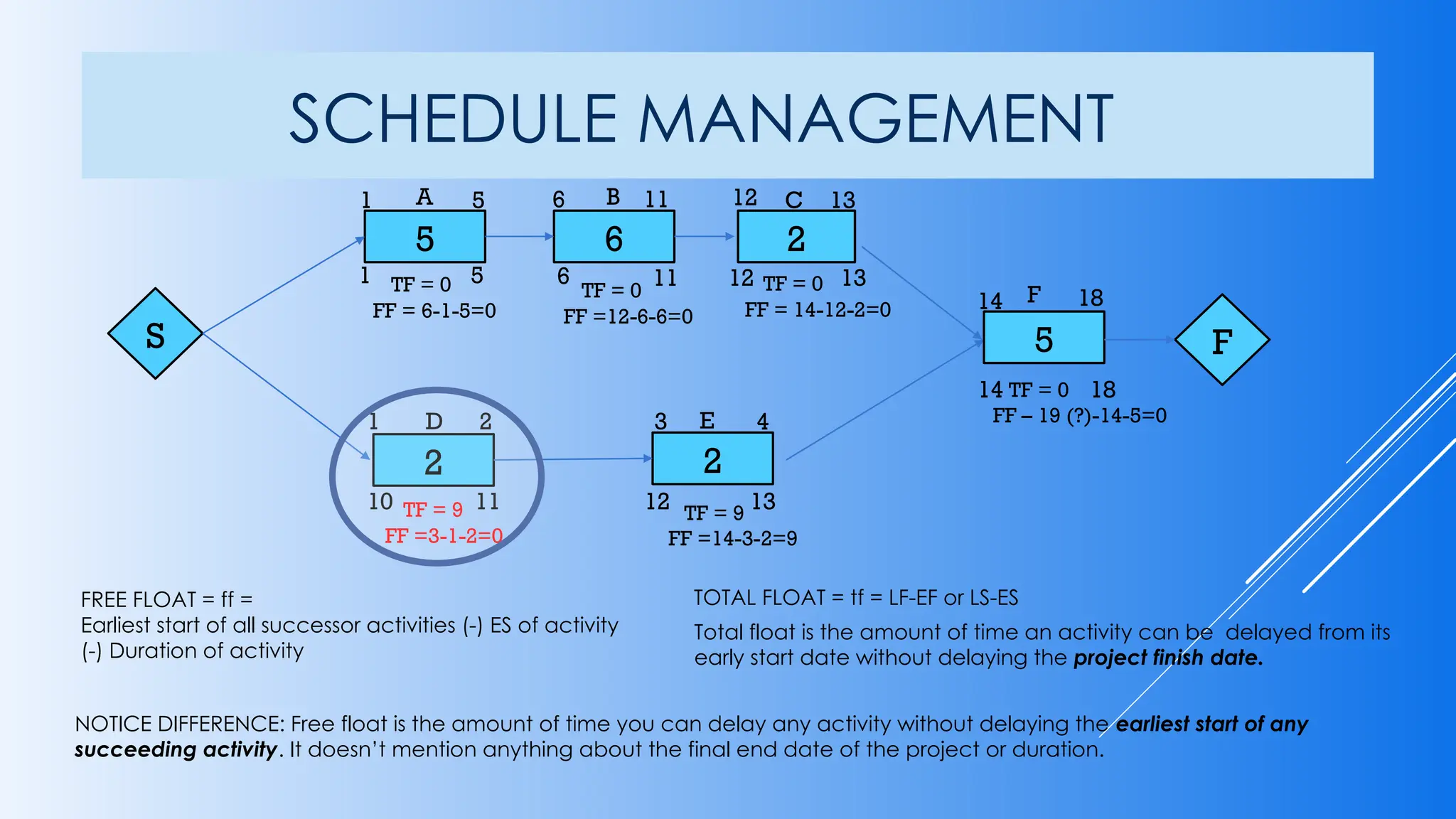

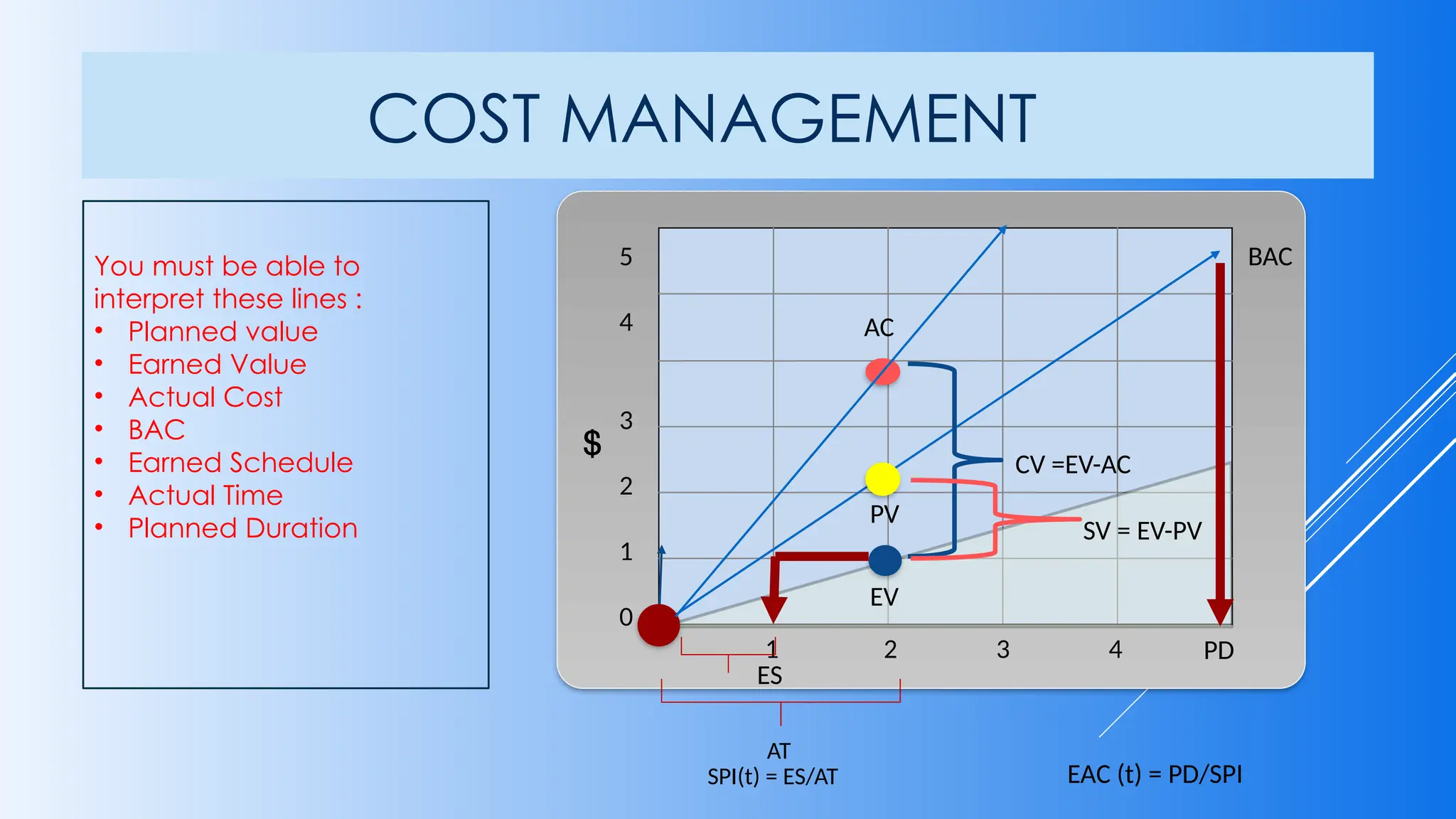

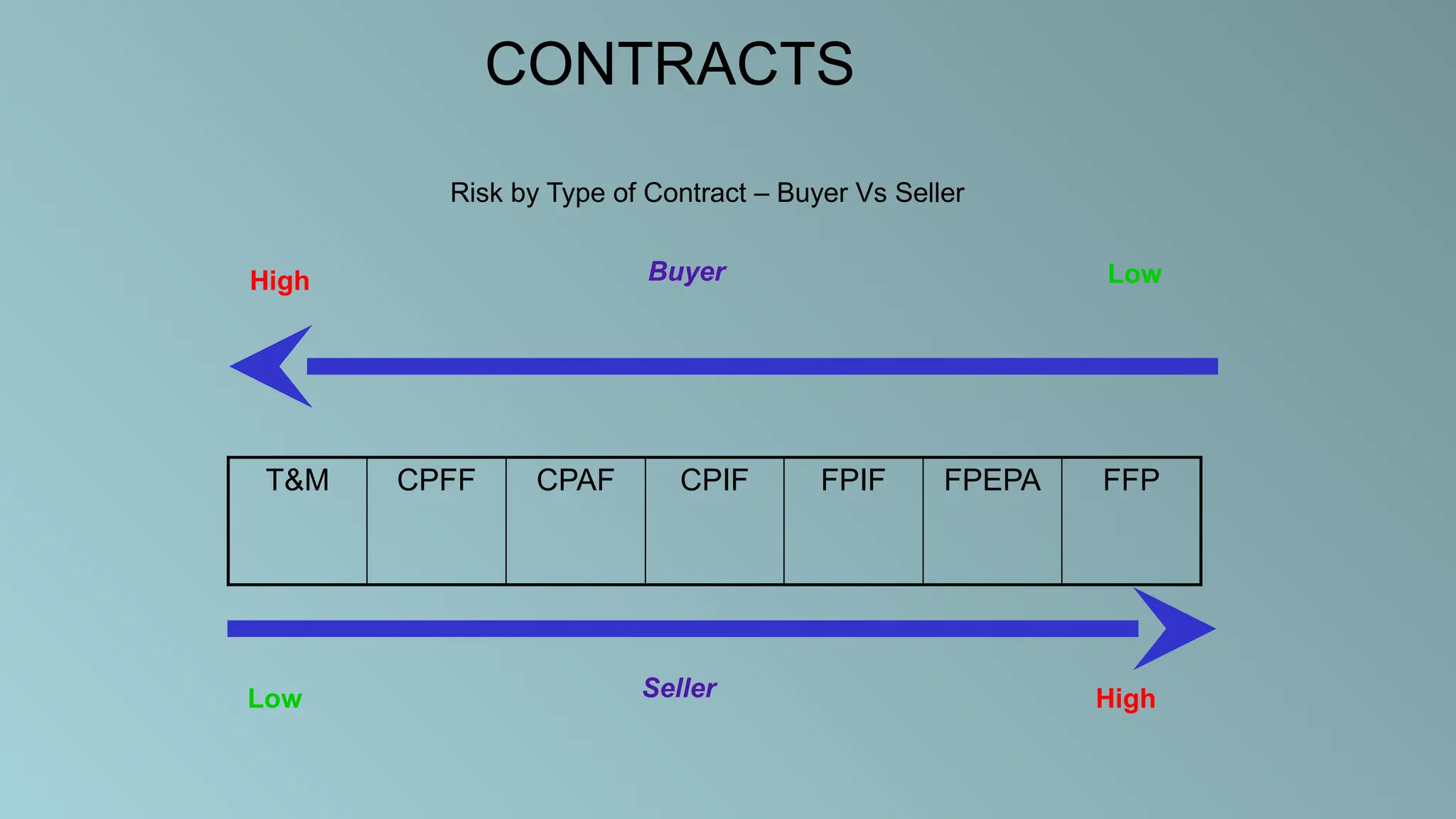

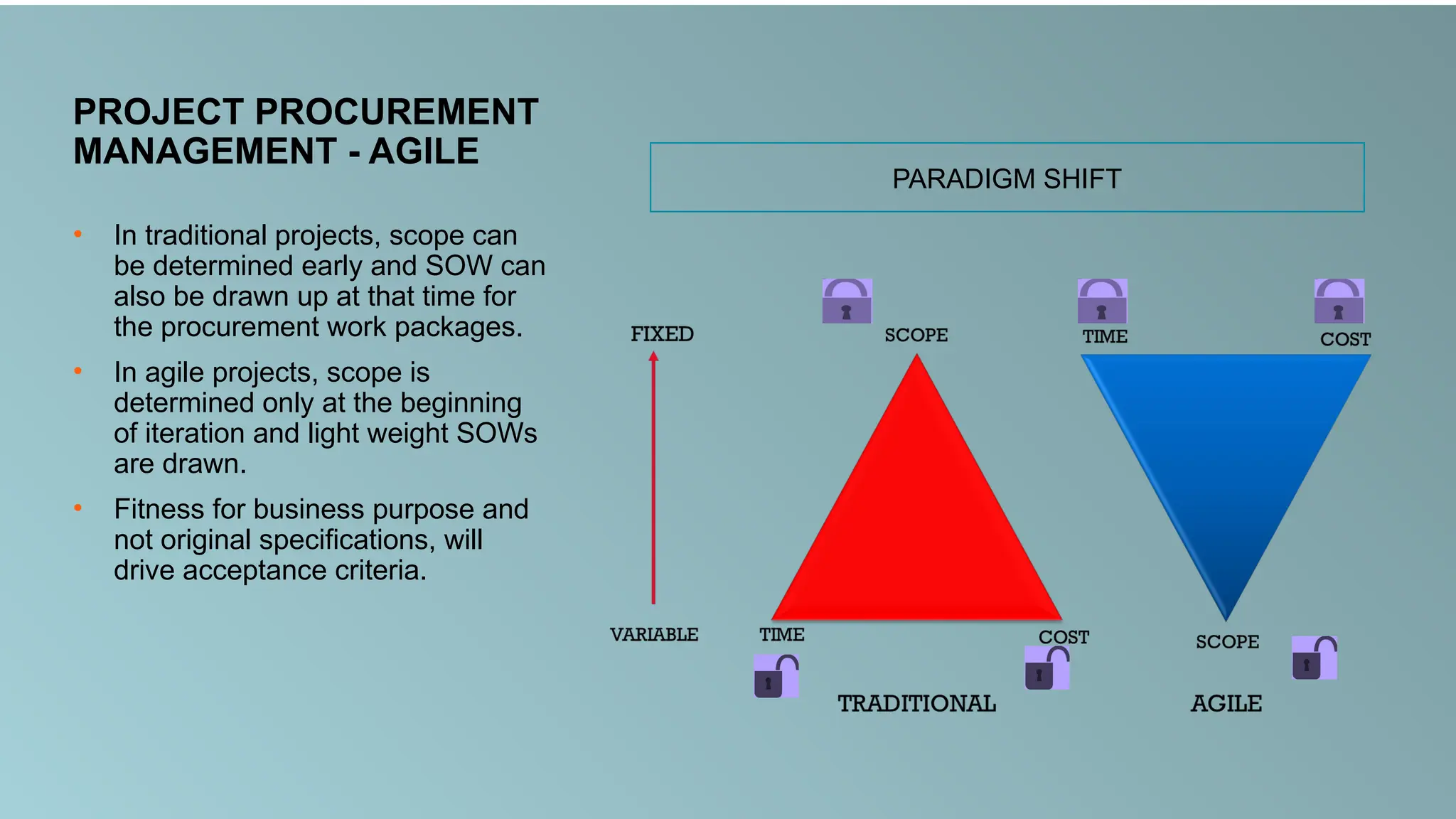

This document serves as a comprehensive guide for PMP studies, covering key topics such as scope management, dependency determination, resource management, and cost management. It provides detailed examples and estimating techniques, including three-point estimating and various methods of managing quality and resources in project management. Additionally, it discusses the implications of schedule constraints, schedule compression strategies like crashing and fast tracking, and tools for effective decision-making and quality assurance.