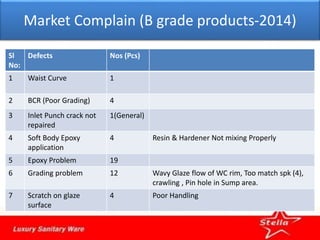

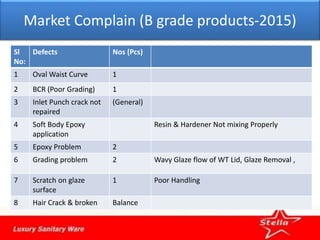

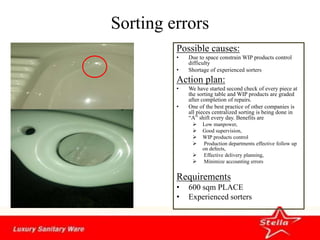

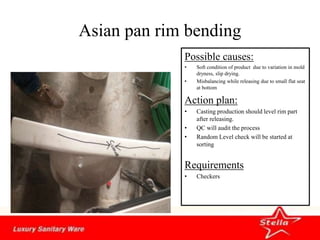

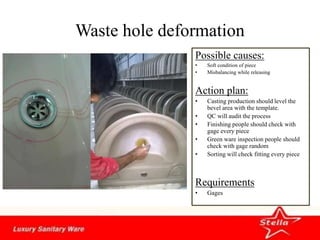

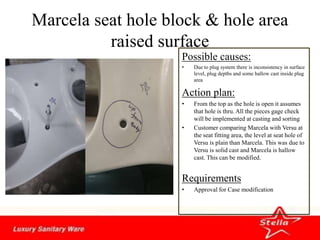

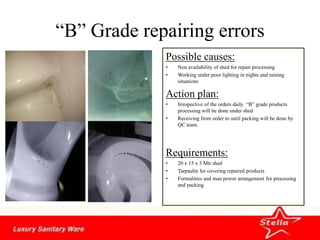

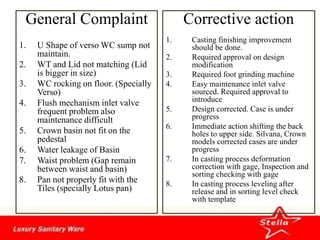

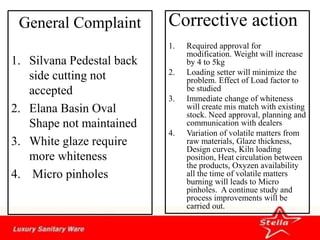

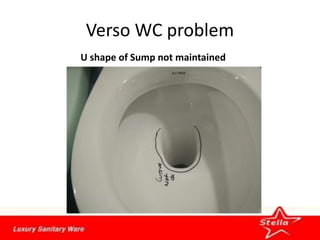

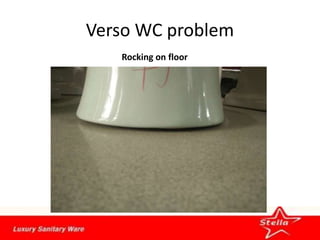

This document summarizes market visit reports and complaints about sanitaryware products from visits to the South region of Bangladesh. It outlines defects reported in A and B grade products from 2014-2015, possible causes, and action plans to address sorting errors, rim bending, waste hole deformation, seat hole issues, repair errors, and general complaints about various models. Solutions proposed include process improvements, design modifications, new equipment, and quality checks.