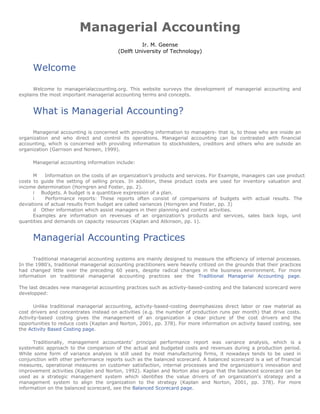

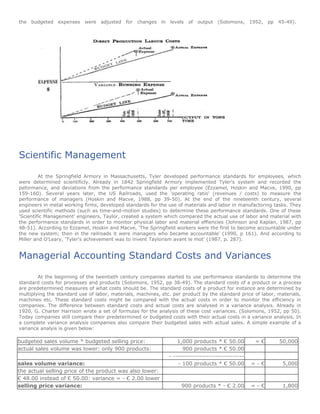

Managerial accounting provides information to managers within an organization to help them direct operations. It focuses on product costs, budgets, performance reports, and other information to assist planning and control. Traditional managerial accounting systems mainly measure internal process efficiency but have been criticized for not changing with the business environment. New practices like activity-based costing and the balanced scorecard were developed to give managers a clearer picture of cost drivers and performance.