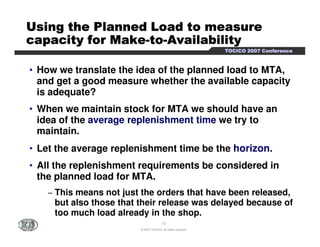

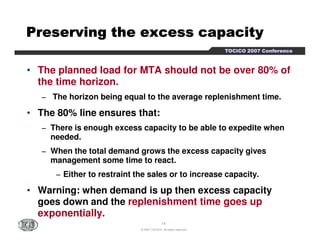

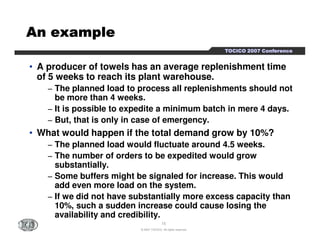

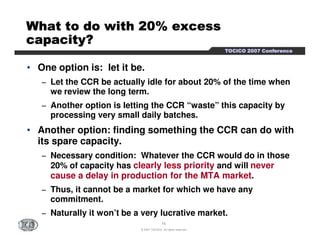

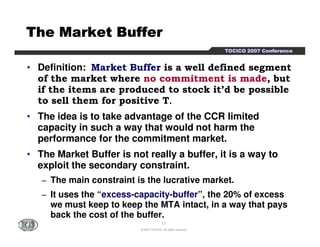

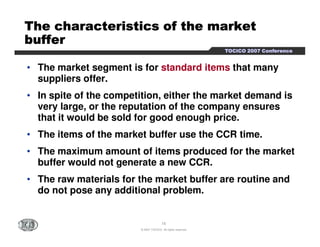

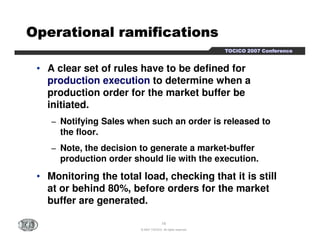

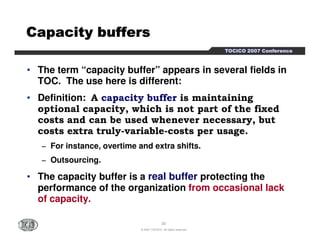

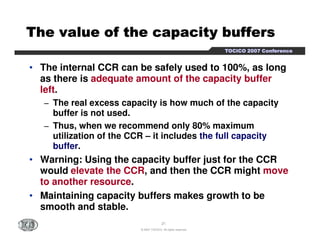

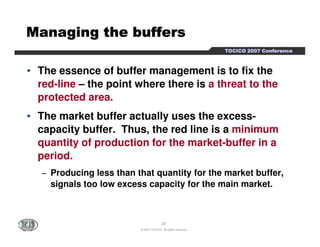

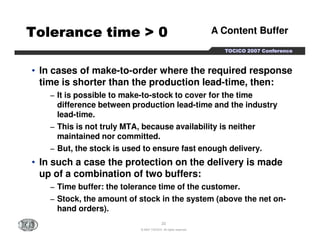

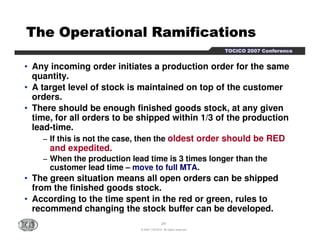

The document discusses the concept of make-to-availability (MTA) which involves maintaining enough inventory to fulfill customer orders immediately upon request at all times. It defines MTA and compares it to make-to-stock. The key challenges of MTA are ensuring strong commitments can be made to customers while maintaining adequate production capacity and inventory buffers to fulfill demand within the needed response time.