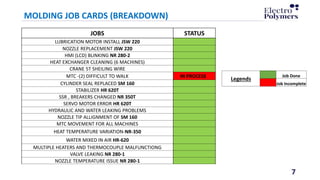

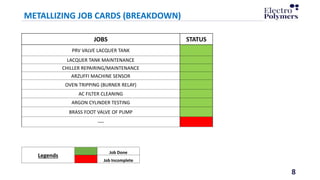

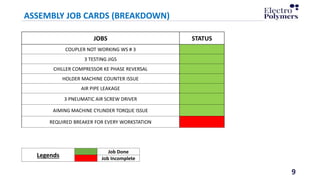

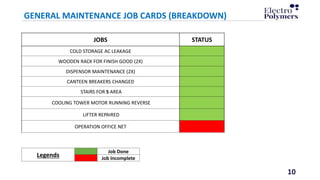

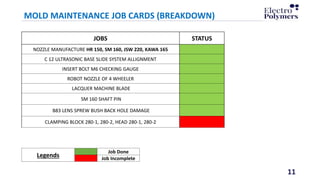

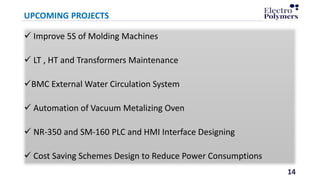

This document discusses the development of department-specific toolboxes to reduce machine downtime during maintenance. Currently, maintenance teams experience delays when they forget tools and have to return to retrieve them. The new toolboxes aim to be well-organized and contain all essential tools for each department to minimize downtime. They will be implemented first in key departments like Molding, Metalizing, Coating, and Assembly. The document also provides examples of ongoing and upcoming maintenance jobs and issues being addressed for different machines and systems.