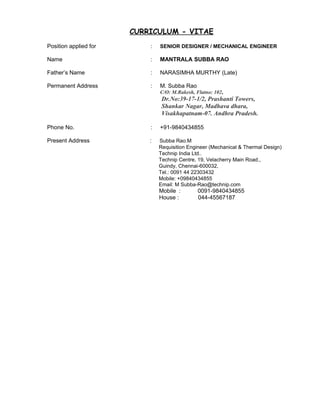

Manthrala Subba Rao is applying for a senior designer/mechanical engineer position. He has over 35 years of experience in designing and checking equipment like drums, columns, heat exchangers, and pressure vessels for refineries, petrochemical plants, and other process facilities. He is proficient in AutoCAD and pressure vessel codes and has worked on numerous international projects around the world.