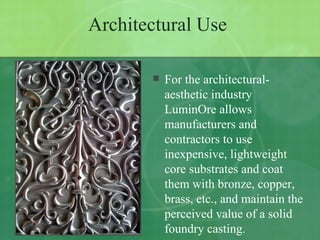

LuminOre has developed a patented cold sprayable metal technology that allows a layer of real metal to be applied over almost any substrate without the weight and expense of solid metal. Their composite metal products look, feel, and act like hot-cast metal and are available in various metals including aluminum, brass, and copper. Testing has shown the products to be highly effective antifouling agents in both fresh and salt water for over 10 years with minimal leaching and maintenance required.