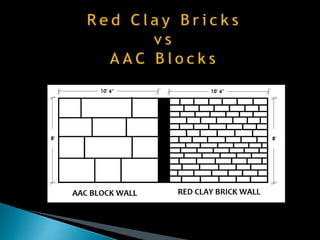

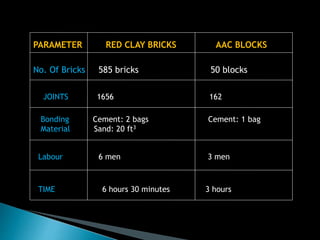

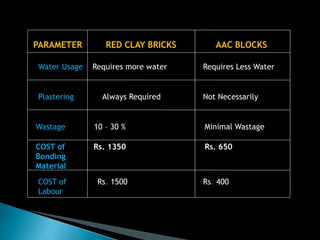

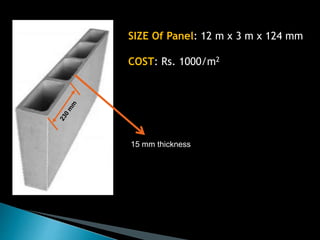

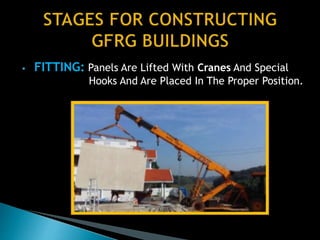

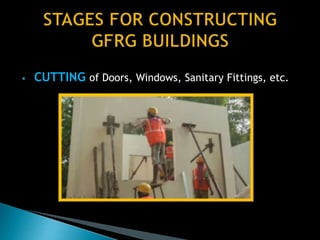

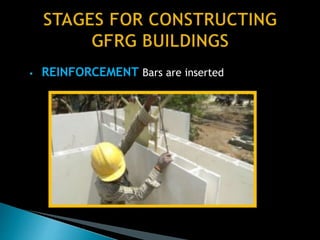

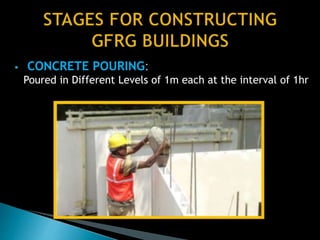

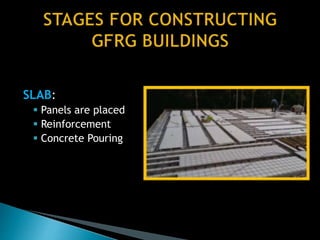

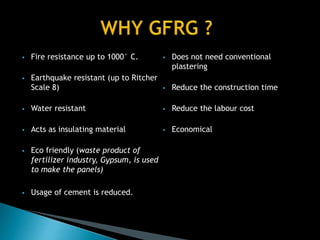

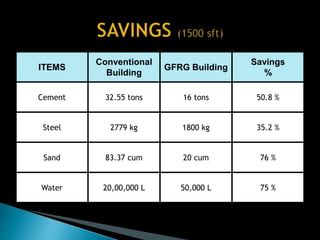

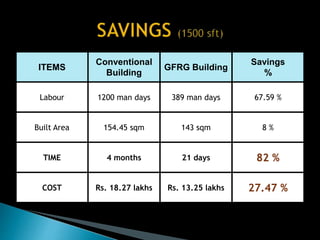

The document discusses the use of alternative building materials, specifically Autoclaved Aerated Concrete (AAC) blocks and glass fiber reinforced gypsum (GFRG) panels, that are cost-effective, environmentally friendly, and reduce construction time and labor costs. It compares the performance, strength, and resource usage of AAC blocks and GFRG panels against conventional materials, highlighting significant savings and enhanced durability in construction. Overall, the findings emphasize a transition towards more sustainable building practices with reduced costs and improved structural performance.