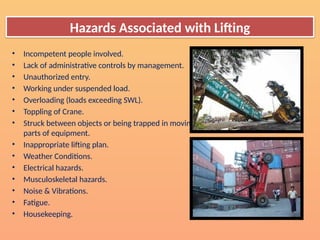

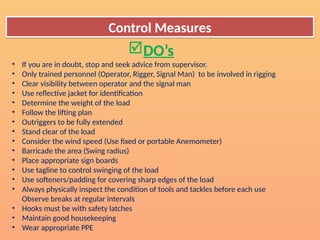

The document outlines lifting and rigging safety training for construction operations, focusing on safe practices, hazard identification, and control measures. It emphasizes the importance of using appropriate lifting equipment, having valid documentation, and implementing a lifting plan to mitigate risks associated with lifting operations. Furthermore, it provides guidelines on do's and don'ts to ensure personnel safety during lifting tasks.