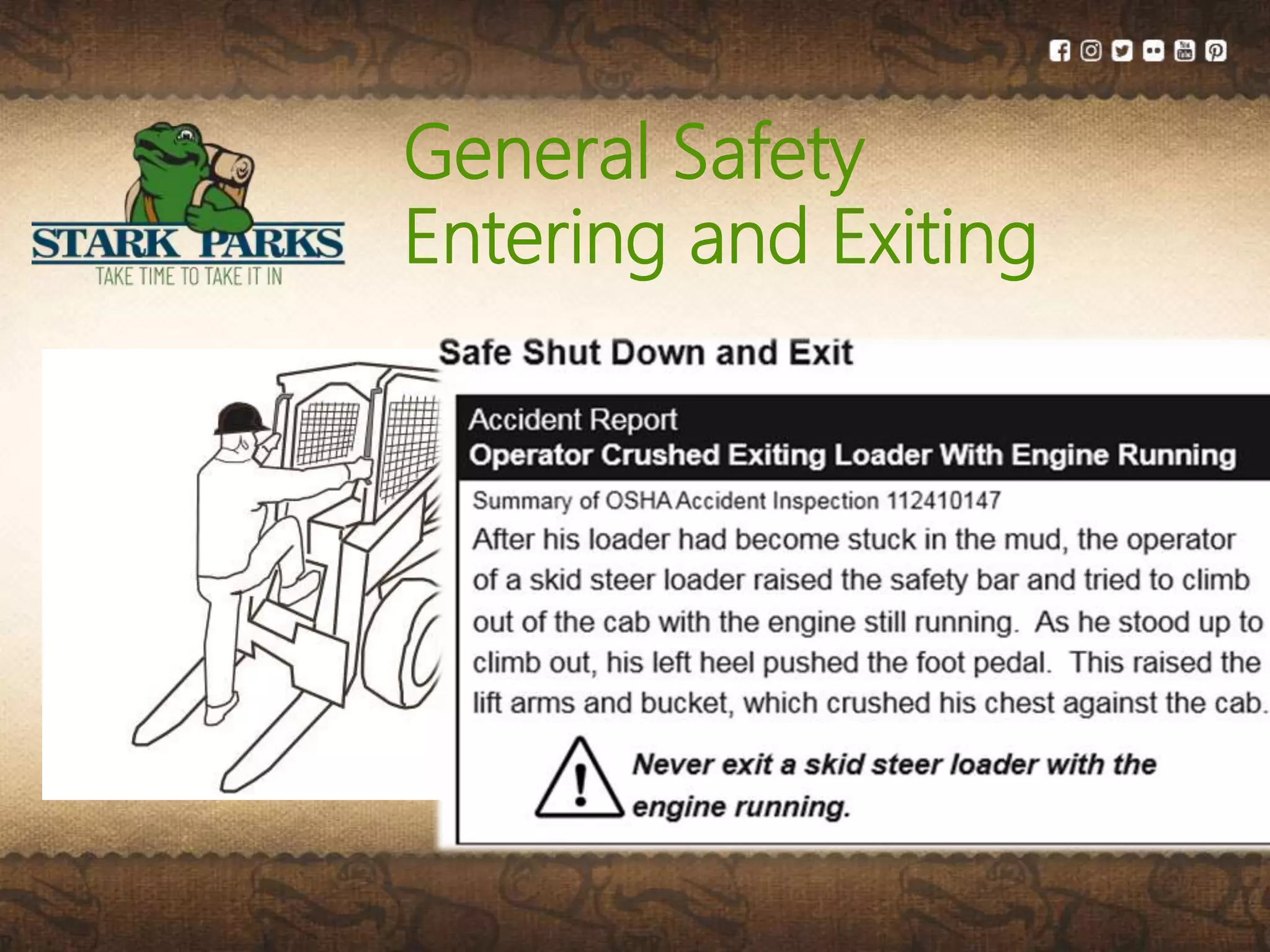

Stark Parks provides training on skid steer loader operation and safety. The training includes online modules, reviewing equipment manuals, and hands-on evaluation. It covers the purpose, controls, attachments and hazards of skid steer loaders. Operators must complete pre-start inspections, enter and exit safely, avoid tipping and crushing hazards, and only use attachments as intended. Maintaining safety is critical when operating these powerful machines.