The document discusses project control and outlines its key aspects:

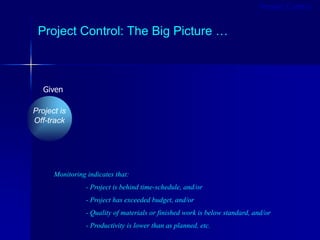

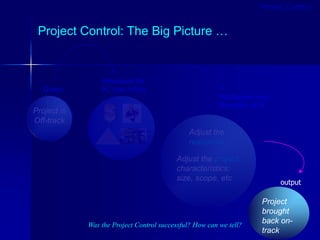

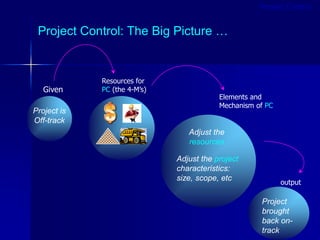

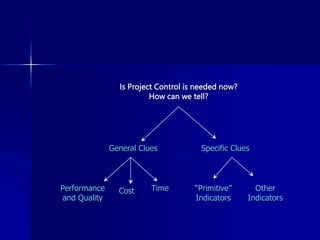

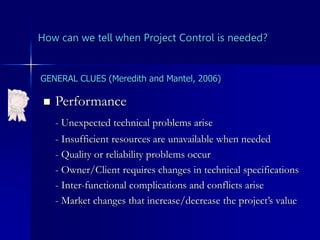

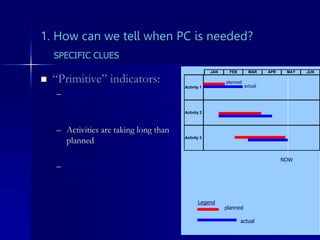

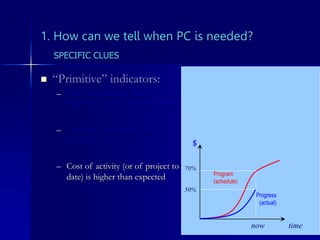

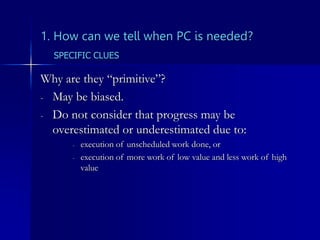

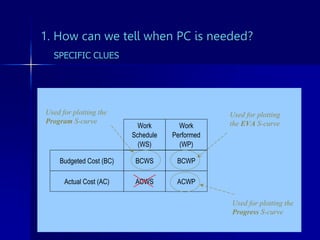

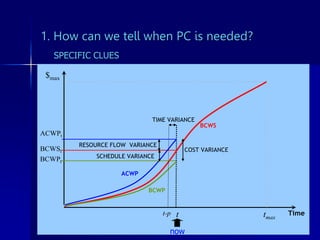

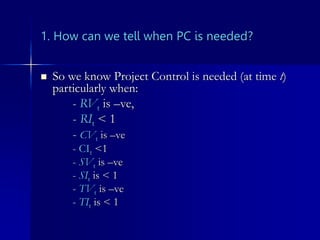

1. It describes how project control is needed when monitoring indicates a project is behind schedule, over budget, or not meeting quality standards.

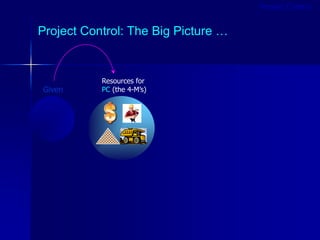

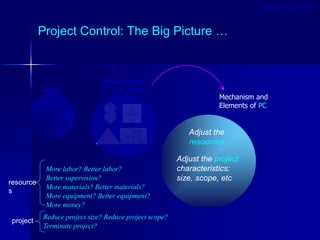

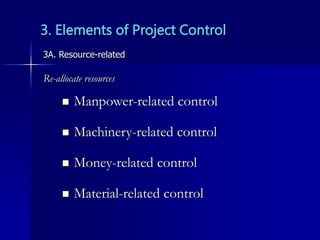

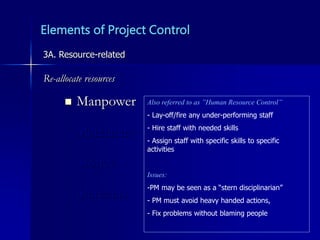

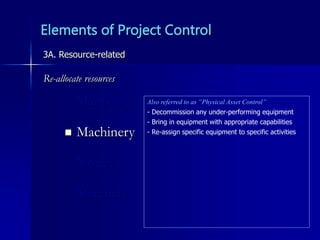

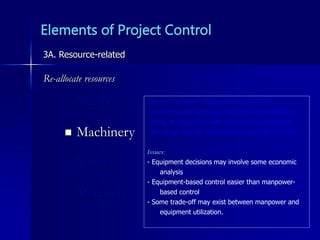

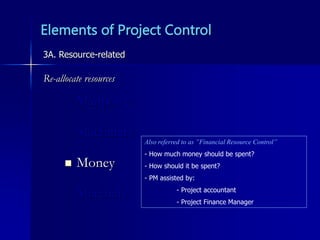

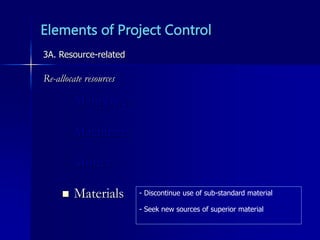

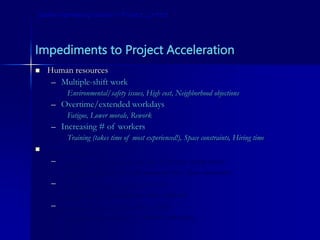

2. It identifies the key resources available for project control: money, manpower, materials, and machinery.

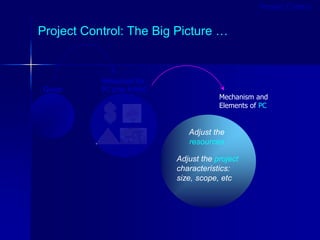

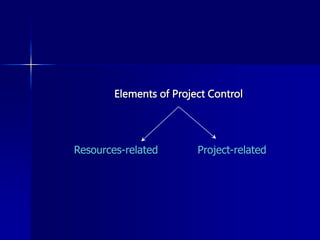

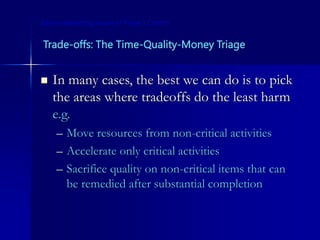

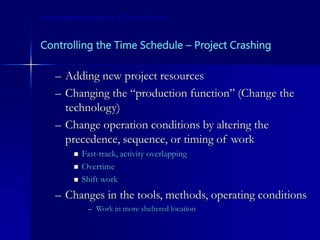

3. The elements of project control include re-allocating resources like staff, equipment, finances, and materials. It also involves adjusting the project's size or scope.

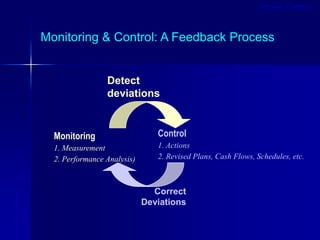

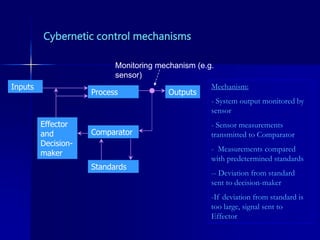

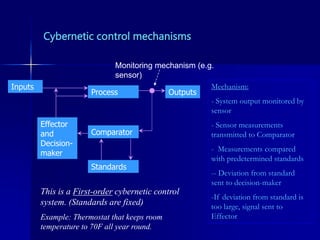

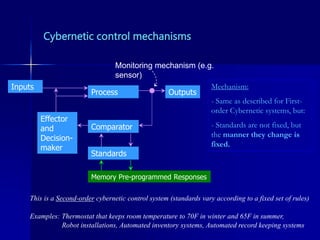

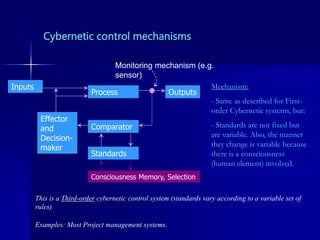

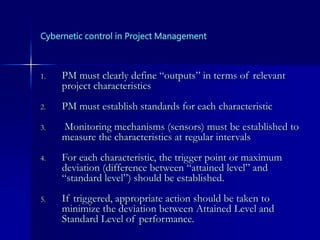

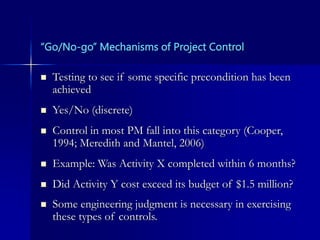

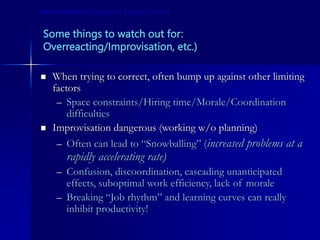

4. The mechanisms of project control include cybernetic control which uses feedback loops to monitor outputs, compare them to standards, and trigger corrective actions when needed.