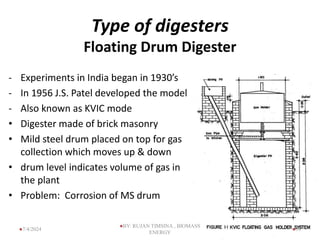

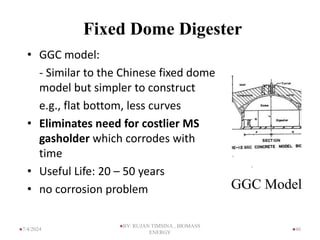

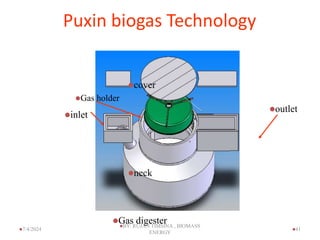

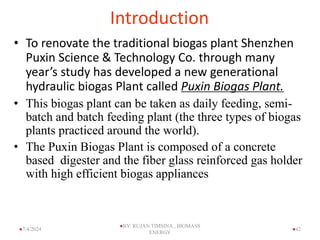

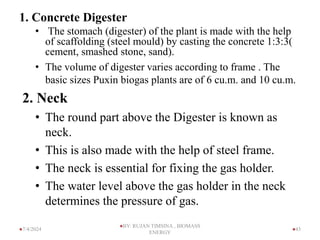

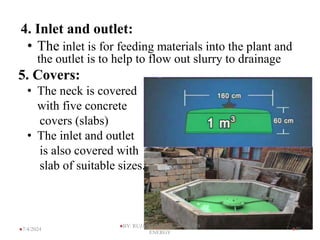

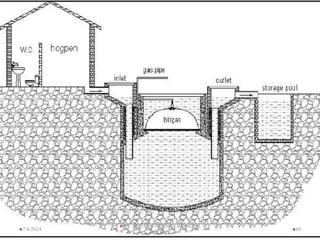

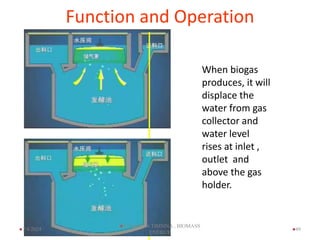

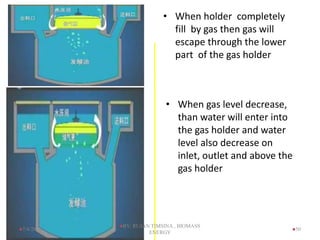

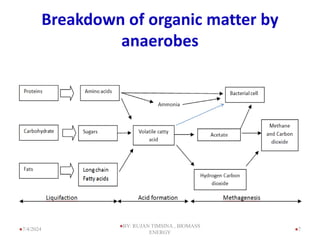

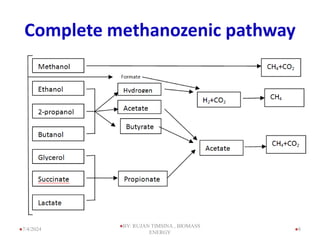

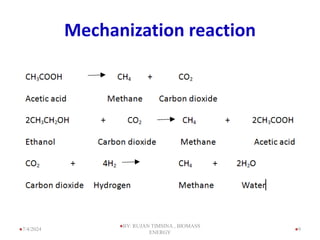

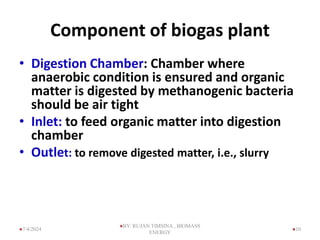

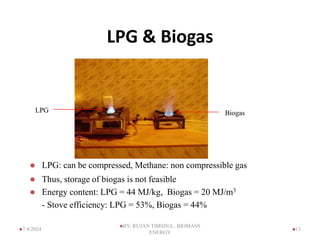

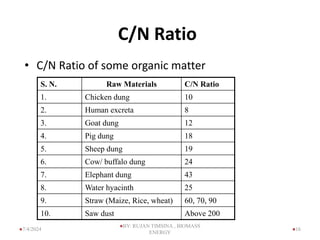

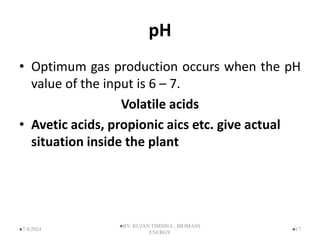

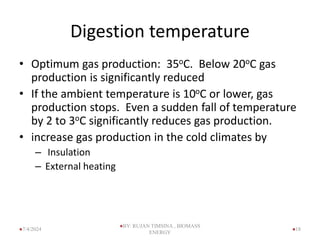

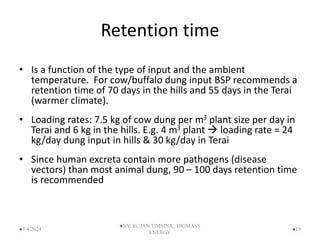

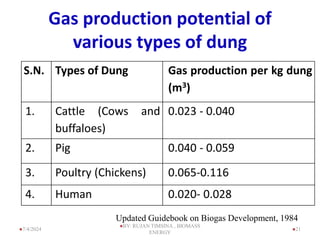

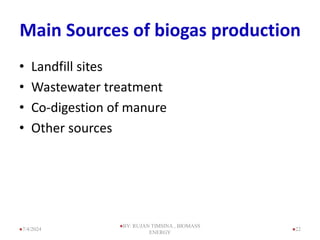

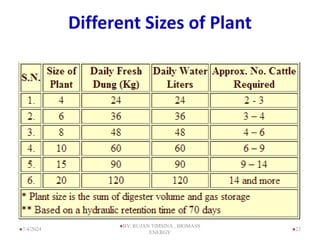

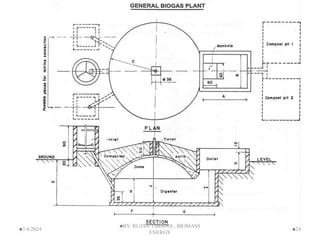

The document discusses biomass energy and biogas production, illustrating its significance, mechanisms, and feedstock sources. It details the anaerobic digestion process, optimal conditions for gas production, and the construction and operation of biogas plants. Additionally, it compares biogas with LPG in terms of efficiency and suitability while providing guidelines for biogas plant construction and operation.

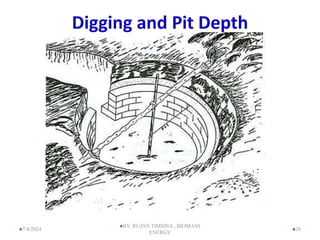

![jfof]UofF;

11

7/4/2024

BY: RUJAN TIMSINA , BIOMASS

ENERGY](https://image.slidesharecdn.com/lecture3biogas-240704184015-28f84dab/85/Lecture-3-Biomass-energy-ppt-11-320.jpg)

![Construction of round wall

8fOh]:6/ / kvf{nsf]

9nfg sfd

30

7/4/2024

BY: RUJAN TIMSINA , BIOMASS

ENERGY](https://image.slidesharecdn.com/lecture3biogas-240704184015-28f84dab/85/Lecture-3-Biomass-energy-ppt-30-320.jpg)

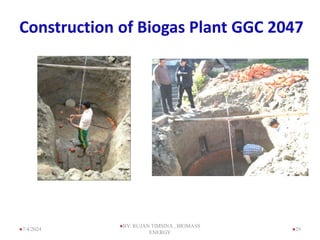

![Construction of Biogas Plant

8fO{h]:6/sf] 8f]dsf] lgdf{0f

31

7/4/2024

BY: RUJAN TIMSINA , BIOMASS

ENERGY](https://image.slidesharecdn.com/lecture3biogas-240704184015-28f84dab/85/Lecture-3-Biomass-energy-ppt-31-320.jpg)