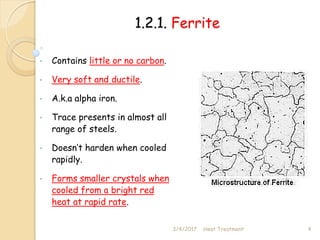

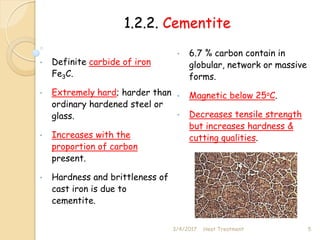

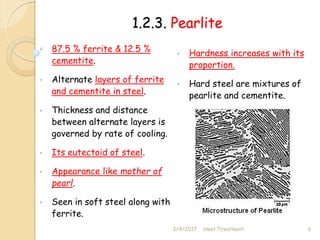

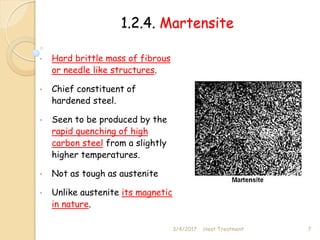

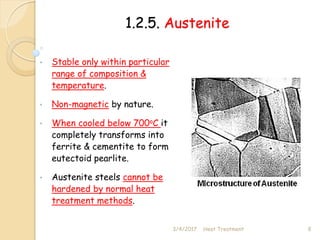

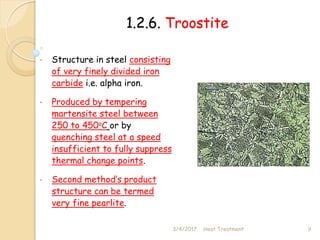

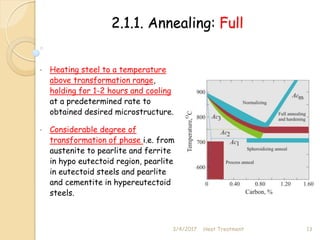

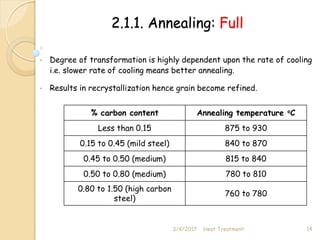

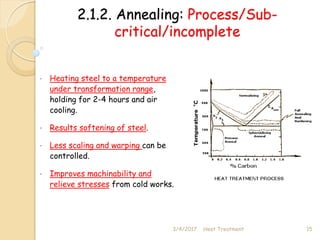

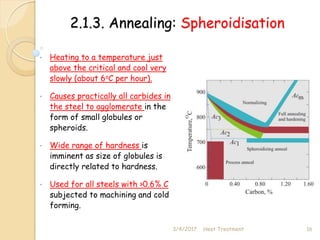

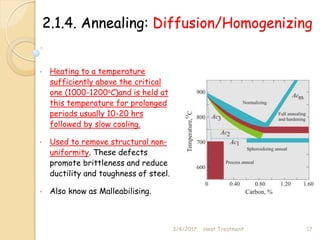

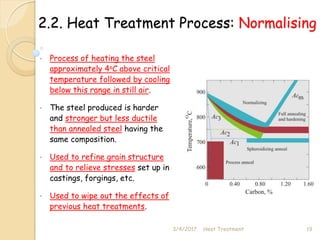

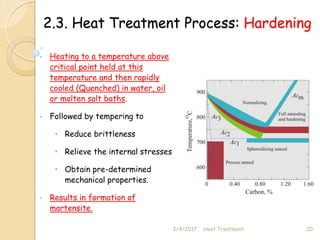

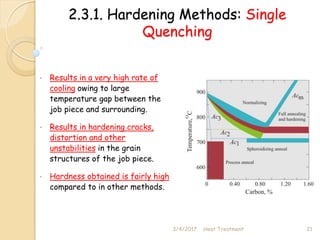

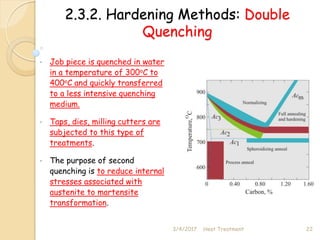

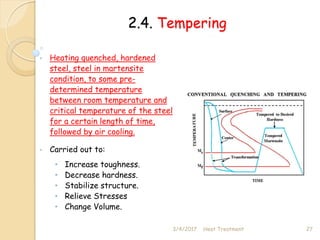

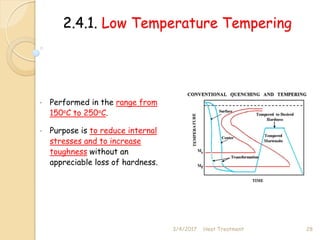

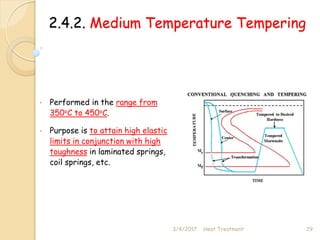

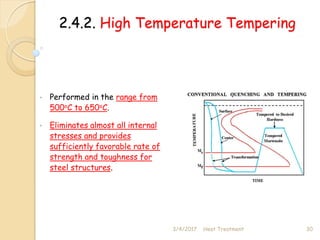

Heat treatment involves heating and cooling metals and alloys to change their properties. It is done for purposes like improving machinability, relieving stresses, and enhancing mechanical properties. The key microscopic constituents of iron and steel that form during heat treatment are ferrite, cementite, pearlite, martensite, austenite, and others. Common heat treatment processes include annealing to soften metals, normalizing to refine grain structure, hardening to increase hardness by rapidly cooling from high temperatures, and tempering to reduce brittleness in hardened steels.