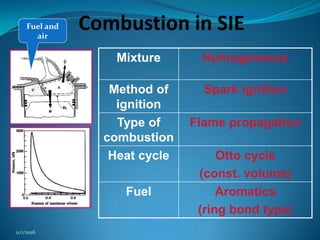

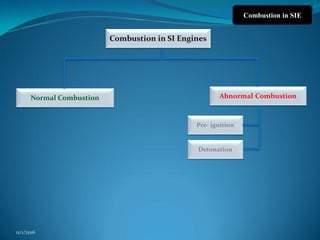

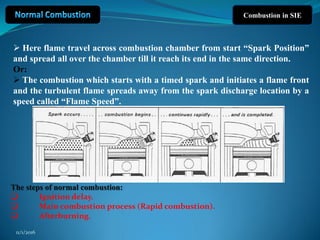

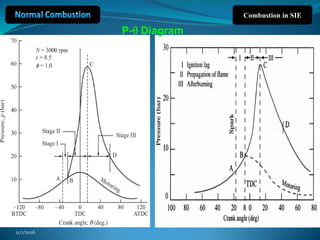

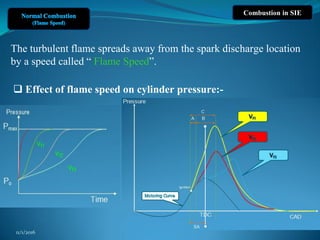

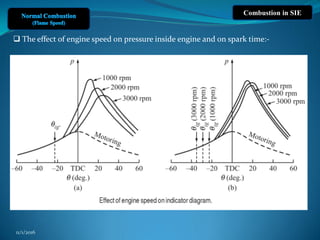

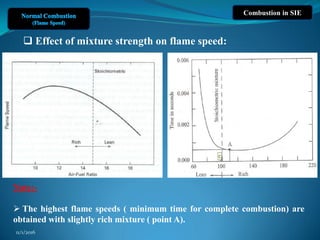

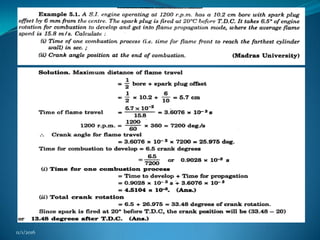

The document discusses combustion in spark ignition (SI) engines, focusing on the ignition delay, main combustion process, and afterburning stages. It highlights the factors affecting flame speed such as load, turbulence, engine speed, compression ratio, inlet temperature and pressure, mixture ratio, and spark timing, illustrating their impact on engine performance and emissions. Understanding these elements is crucial for optimizing combustion efficiency and minimizing pollutants in SI engines.