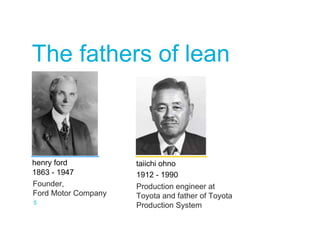

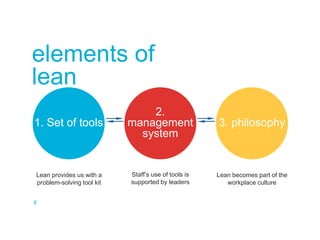

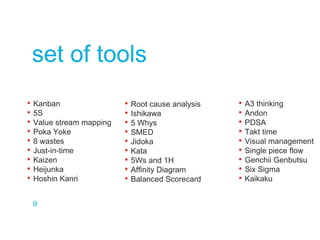

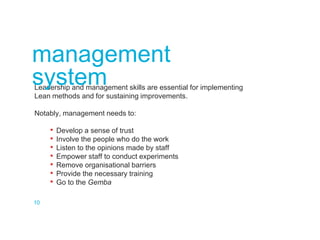

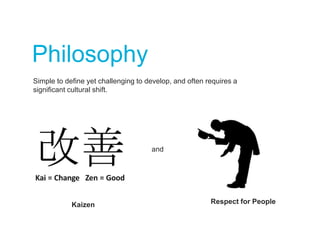

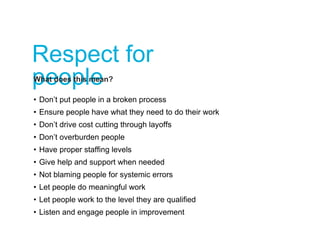

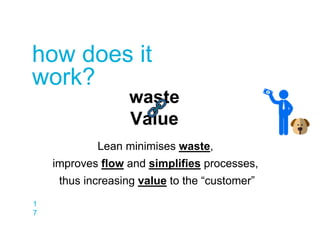

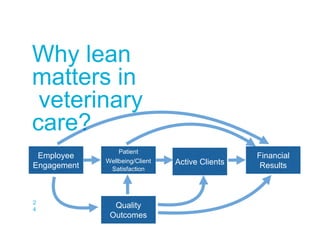

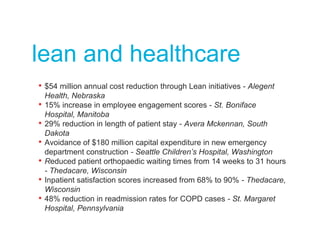

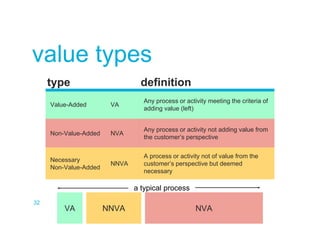

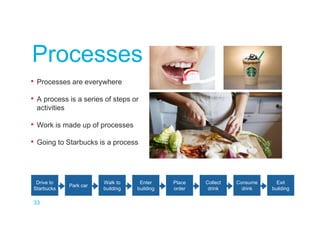

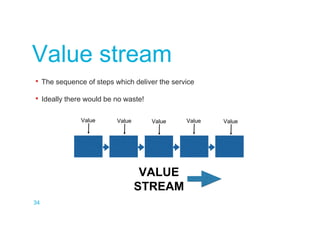

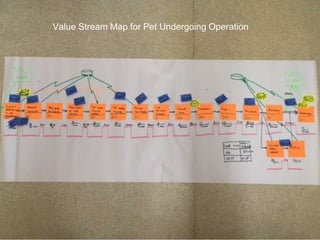

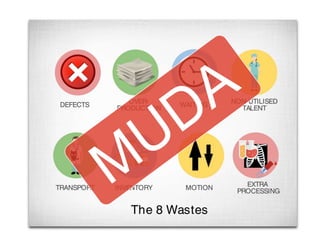

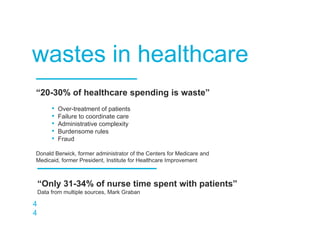

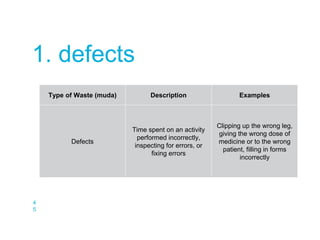

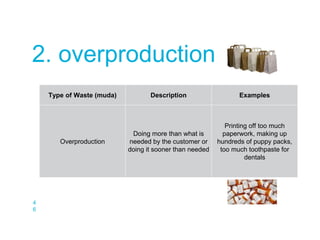

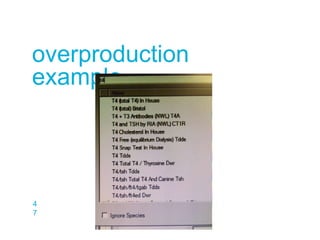

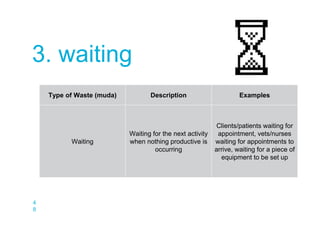

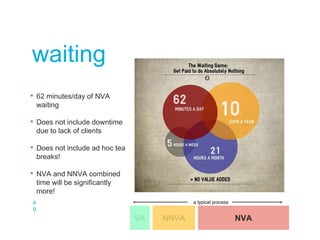

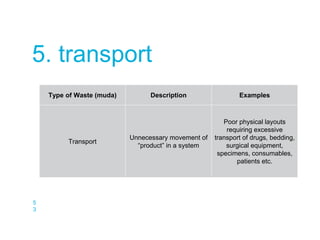

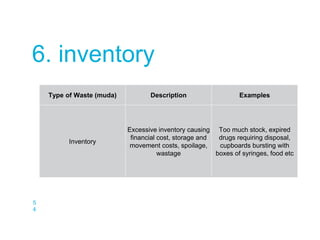

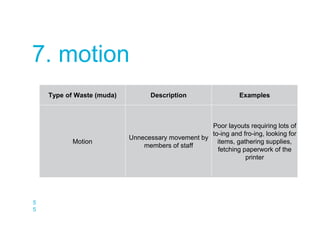

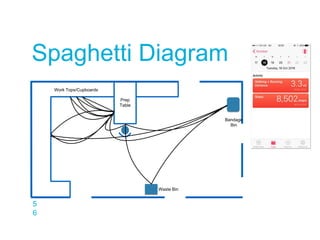

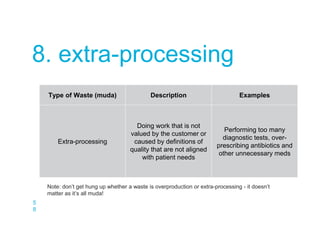

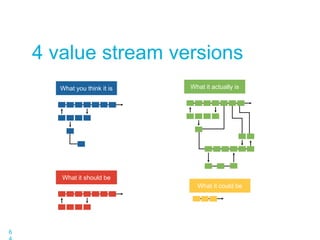

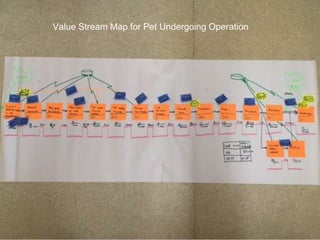

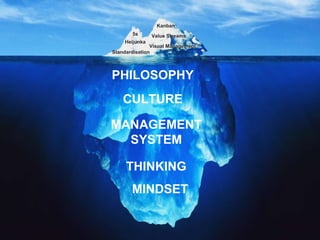

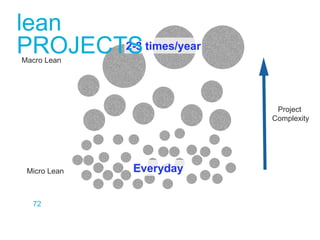

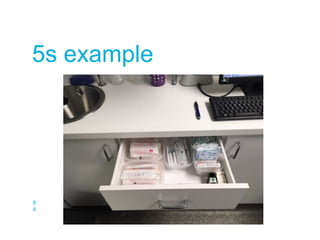

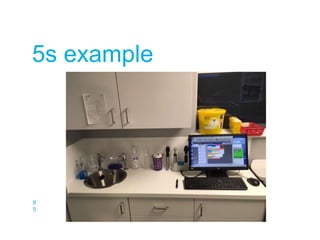

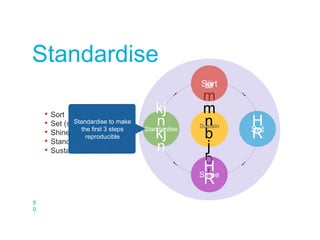

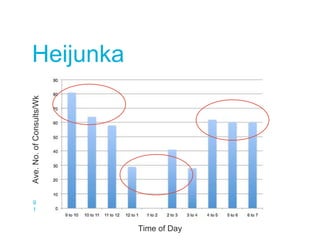

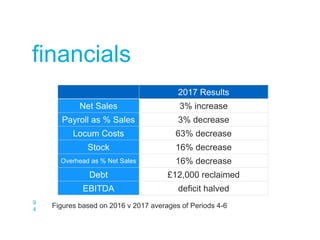

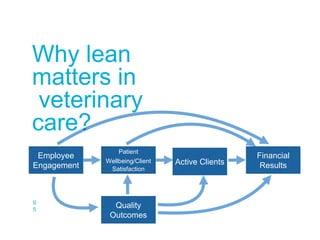

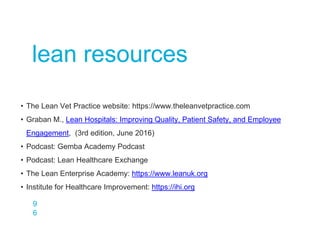

The document discusses the implementation of lean principles in veterinary care to enhance efficiency and improve service delivery. It outlines key concepts such as continuous improvement, waste reduction, and employee engagement while providing examples of successful applications in healthcare settings. The ultimate goal is to create a culture that prioritizes value-added activities, benefiting both staff and clients.