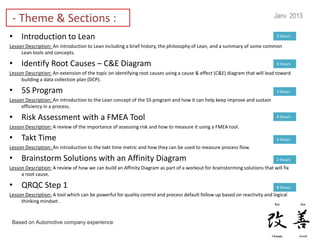

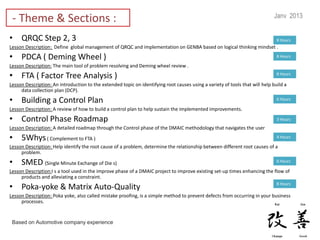

This document outlines a training program on Lean Manufacturing practices. It lists several Lean tools and concepts that will be covered in the training, including introduction to Lean, identifying root causes, 5S, risk assessment with FMEA, takt time, affinity diagrams, QRQC steps 1 and 2, PDCA, FTA, building control plans, 5 whys, SMED, poka-yoke and auto-quality. The training will total approximately 97 hours and cover topics such as process improvement philosophies, identifying issues, organizing workspaces, risk analysis, workflow analysis, problem solving tools, sustaining improvements and mistake proofing.