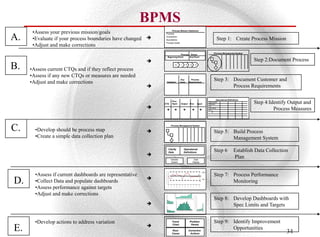

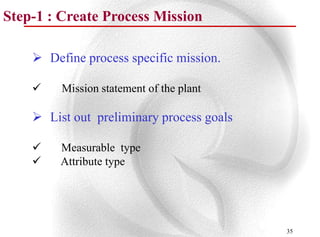

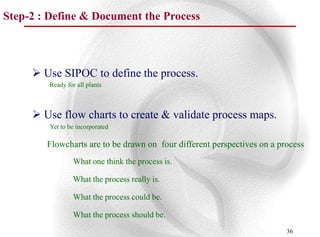

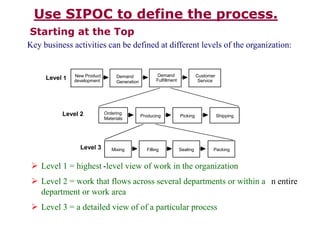

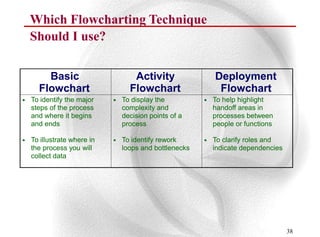

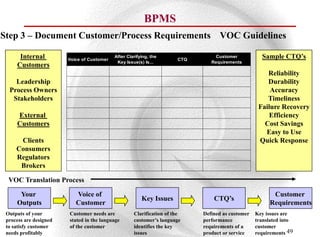

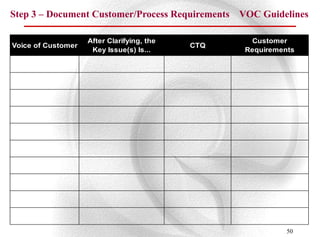

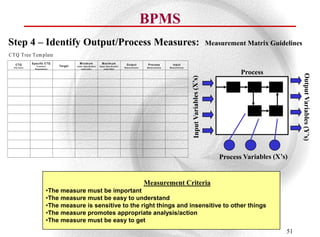

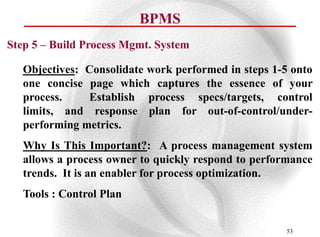

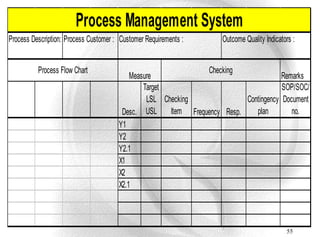

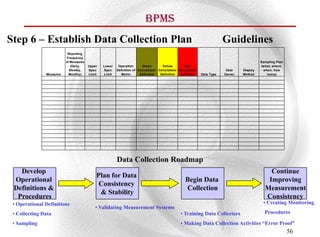

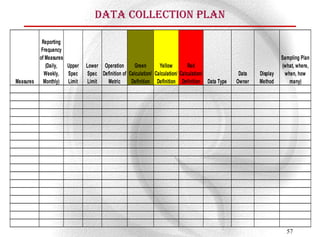

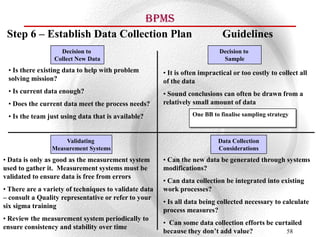

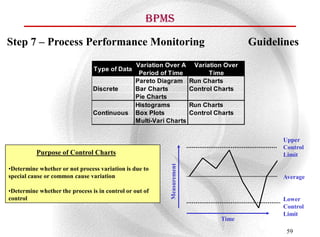

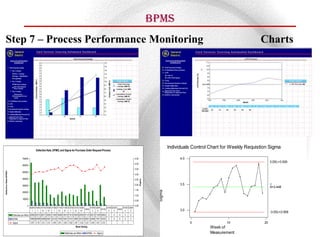

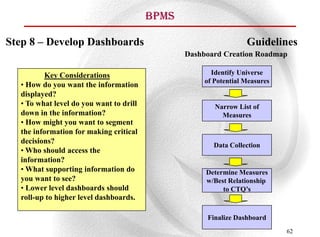

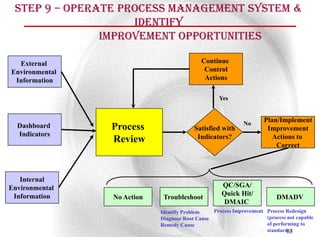

The BPMS (Business Process Management System) is a 9-step methodology to optimize process performance and establish value-added metrics. The steps include: 1) creating a process mission statement, 2) documenting the process, 3) identifying outputs and measures, 4) building a process map, 5) establishing a management system, 6) creating a data collection plan, and 7) ongoing performance monitoring. The goal is to create ongoing accountability for managing cross-functional processes to satisfy goals.

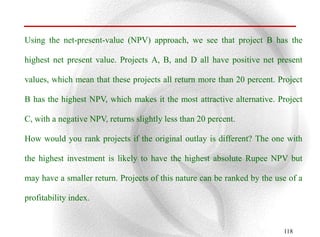

![Leadership Vision

• “Quality . . . is the next opportunity for our Company to

set itself apart from its competitors . . .

... Dramatically improved Quality will increase employee

and customer satisfaction, will improve share and

profitability, and will enhance our reputation.

... “[Six Sigma] is the most important training

thing we have ever had. It’s better than going

to Harvard Business School.”

J.F. Welch

26](https://image.slidesharecdn.com/lean-manufacturing-and-six-sigma-100218051625-phpapp01/85/Lean-Manufacturing-And-Six-Sigma-26-320.jpg)

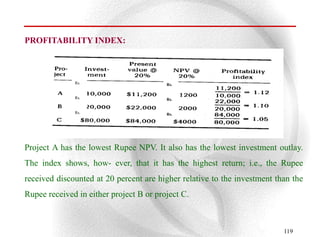

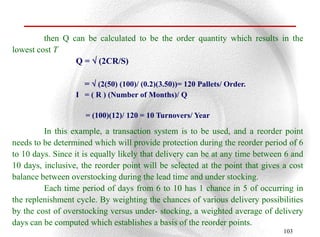

![In this example it may be computed as follows:

Number of items demanded per day = 100/20* = 5 .

*20 days assumes a 5-day workweek

Average cost of overstocking = (5)( 3.50)(1/5)(x- 5)

where x = delivery period between 6 to 10 days

Average cost of under stocking =(10 X 1/5)[10-(x -5)]

Solving for x as the point where the weighted-average overstocking

cost equals the weighted-average under stocking cost:

(5)(3.50)(1/5)(x- 5) = (10)(1/5)(10 -x)

3.5x- 17.5 = 20 -2x

5.5x = 37.5

x= 6.8

104](https://image.slidesharecdn.com/lean-manufacturing-and-six-sigma-100218051625-phpapp01/85/Lean-Manufacturing-And-Six-Sigma-104-320.jpg)