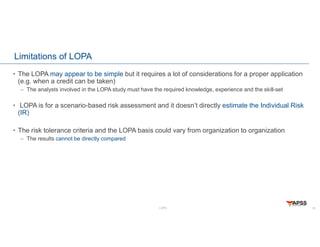

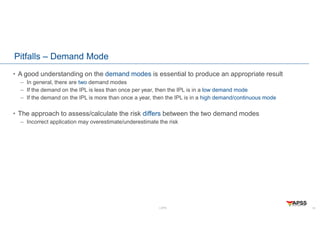

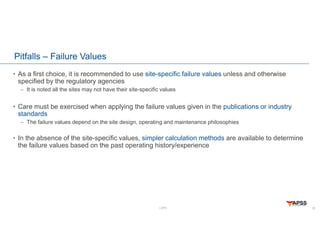

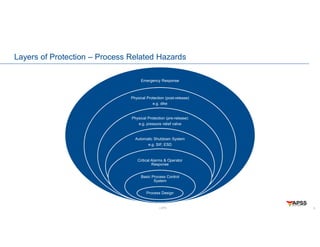

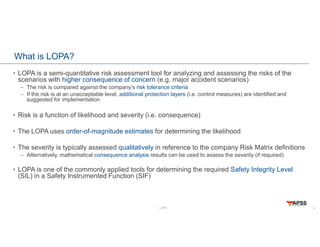

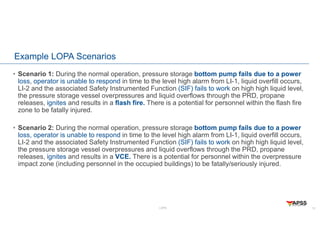

The document provides a comprehensive overview of Layer of Protection Analysis (LOPA), a semi-quantitative risk assessment tool used to analyze major accident scenarios and determine the necessary safety integrity levels for processes. It discusses the historical context of LOPA, exemplified by the Bhopal incident, and outlines its application, terminology, assessment process, limitations, and potential pitfalls. LOPA's effectiveness relies on a thorough understanding of the associated risks and the independence and reliability of protection layers.

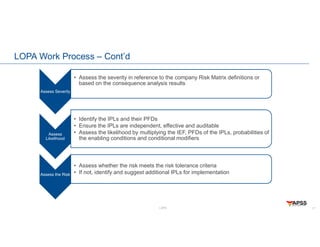

![LOPA

LOPA Work Process

16

Risk Tolerance

• Establish the company risk tolerance criteria

Hazard

Identification

• Identify the hazards and consequence of concern

• Establish the boundaries for the consequence of concern [e.g. safety or

(safety AND environment) or (safety AND environment AND business

impact)]

Initiating Event

Identification

• Identify the Initiating Events (IEs) and the Initiating Event Frequencies (IEF)](https://image.slidesharecdn.com/lopaintroduction-240924015411-985076fc/85/Layer-of-Protection-Analysis-Introduction-16-320.jpg)