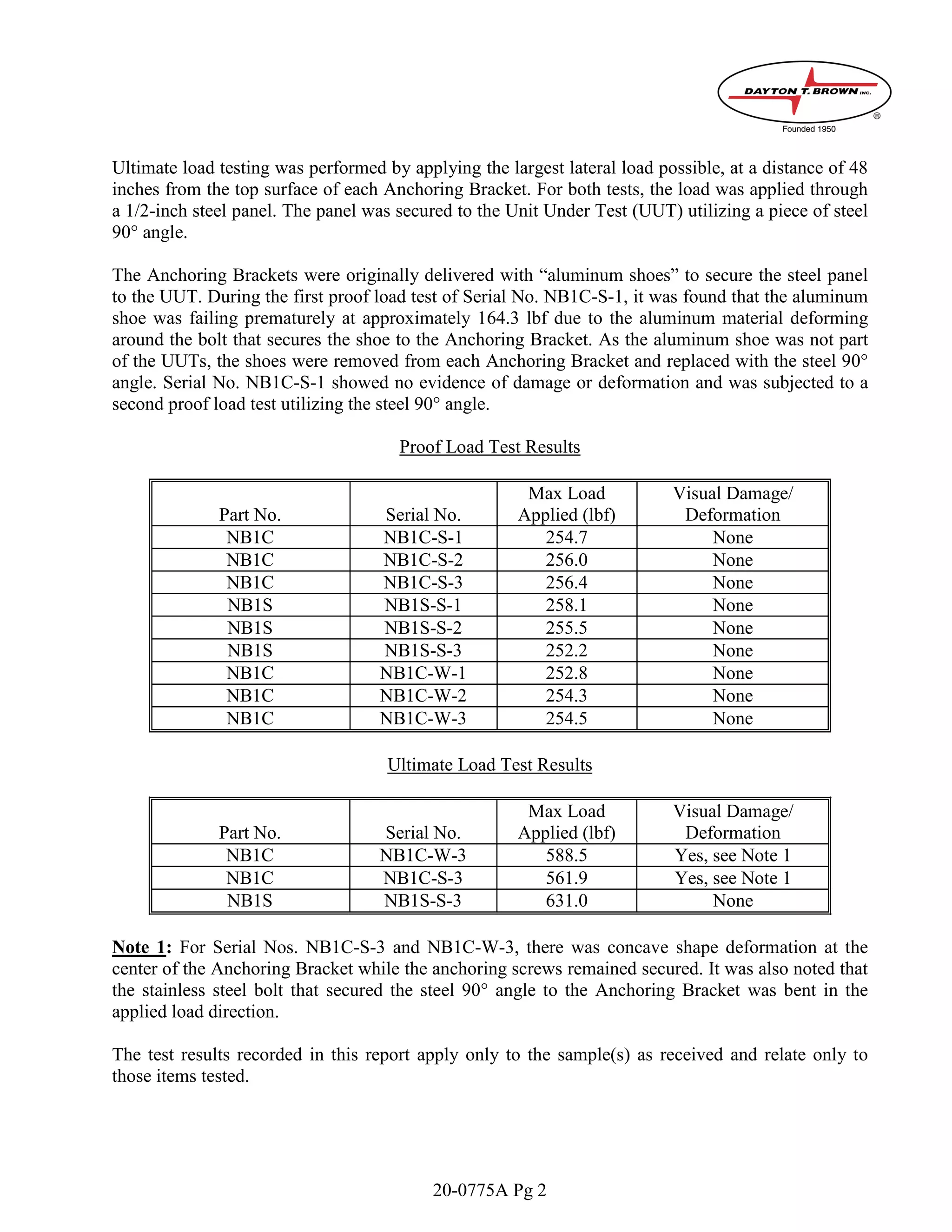

Three types of anchoring brackets were tested under various load configurations:

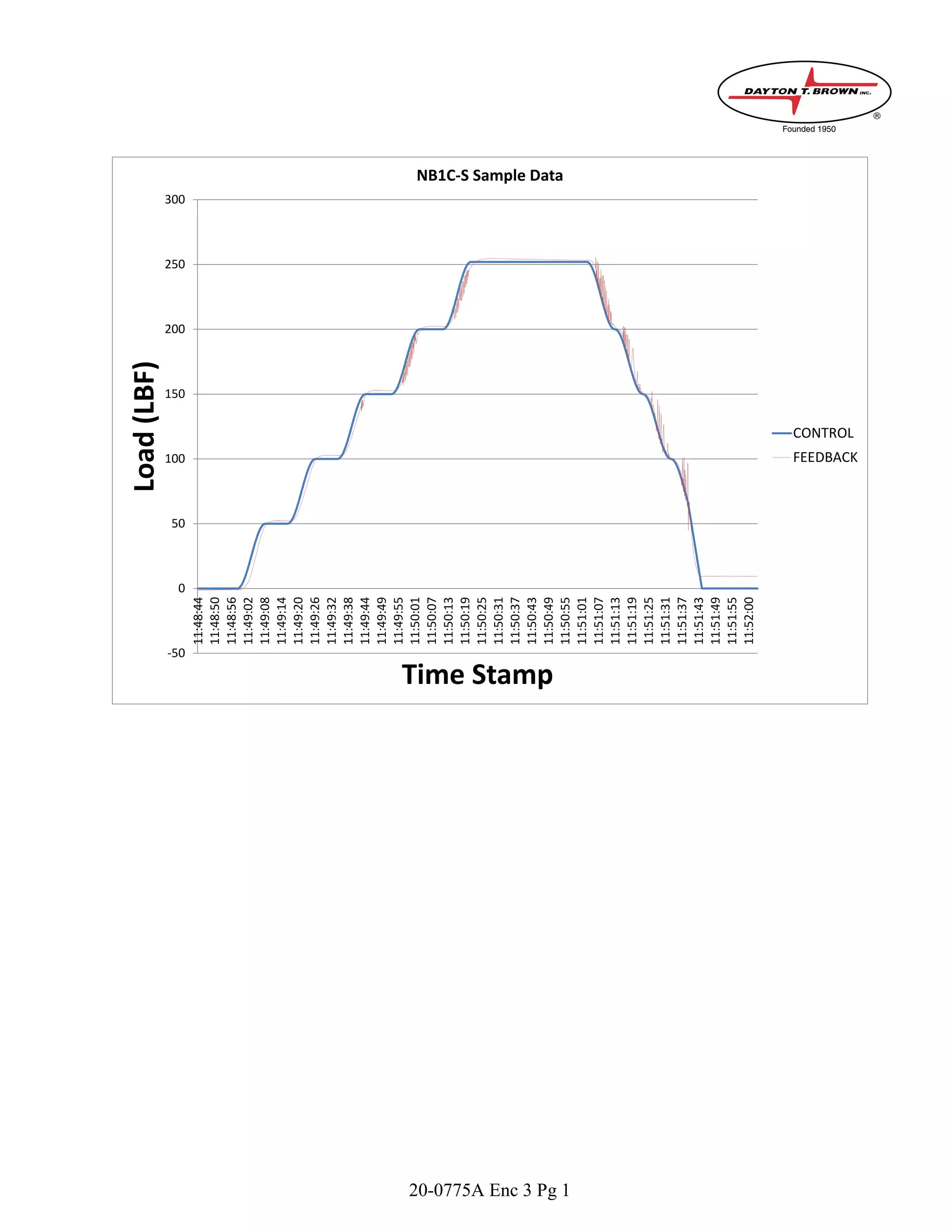

1) Three NB1C brackets bolted to steel tube with six bolts.

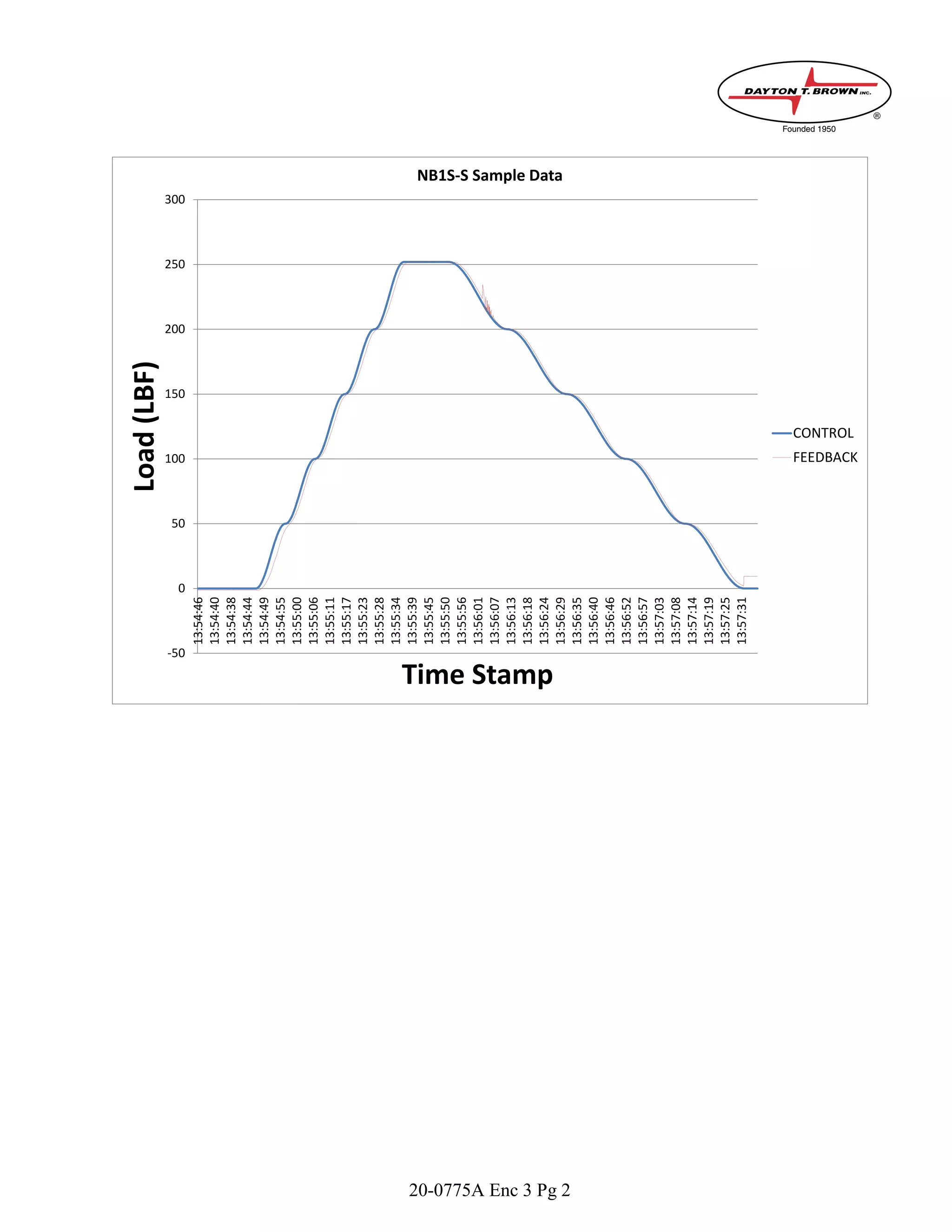

2) Three NB1S brackets welded to steel tube with a through bolt and nut.

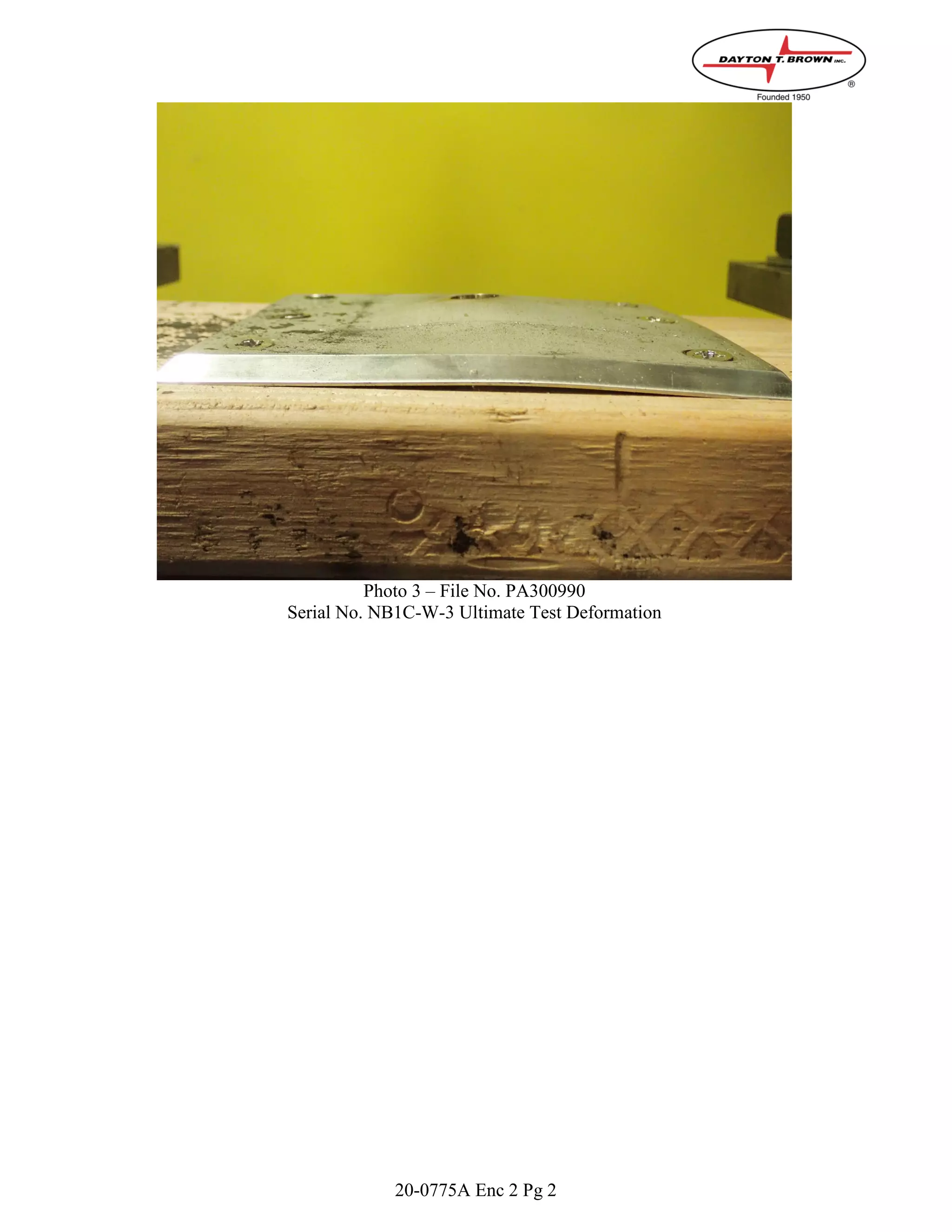

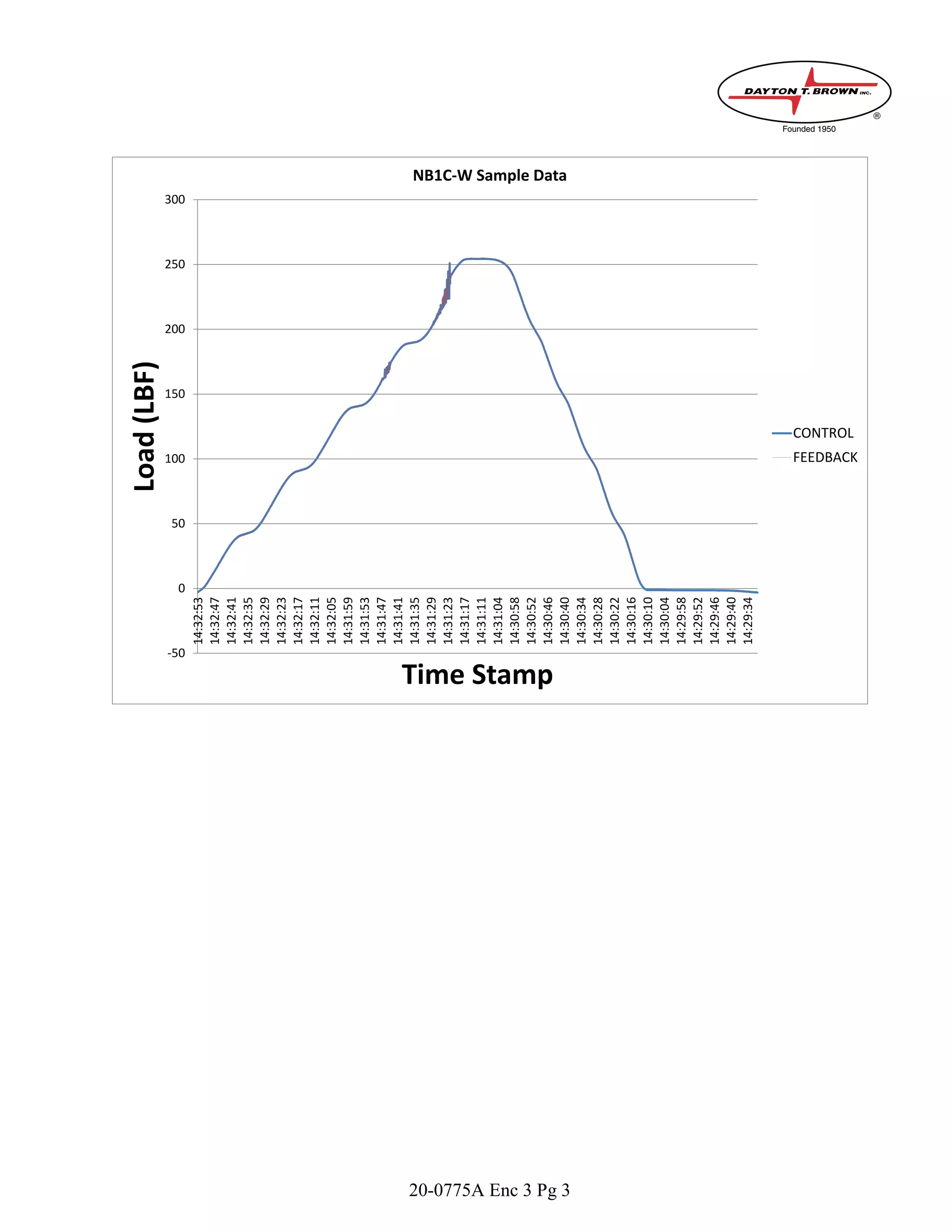

3) Three NB1C brackets lag screwed to stacked wood pieces.

All brackets withstood proof loads up to 258 lbf without damage. Two brackets withstood ultimate loads of 588 and 562 lbf with minor deformation; the third withstood 631 lbf without issues. Aluminum attachment shoes initially failed and were replaced with steel angles.