The document provides an overview of laser safety fundamentals including:

- The properties that make laser light hazardous including being monochromatic, coherent, and highly directional.

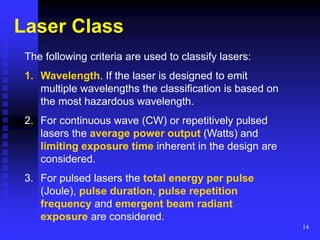

- Common laser types categorized by wavelength output.

- Laser output characteristics such as continuous wave vs pulsed output.

- Types of laser hazards including those to the eye, skin, and from electrical and chemical sources.

- Symptoms of laser eye injuries and classifications of lasers based on their hazard potential outlined in safety standards.

- Control measures like engineering controls, administrative procedures, and personal protective equipment including laser safety eyewear.

![19

Hazard Terms

Maximum Permissible Exposure (MPE)

The MPE is defined in ANSI Z-136.1"The level of laser radiation to

which a person may be exposed without hazardous effect or adverse

biological changes in the eye or skin."

The MPE is not a distinct line between safe and hazardous exposures.

Instead they are general maximum levels, to which various experts

agree should be occupationally safe for repeated exposures.

The MPE, expressed in [J/cm^2] or [W/cm^2], depends on the laser

parameters:

• wavelength,

• exposure duration,

• pulse Repetition Frequency (PRF),

• nature of the exposure (specular, diffuse reflection).](https://image.slidesharecdn.com/laserssafety-240202152345-56528b7a/85/LASERSsafety-ppt-19-320.jpg)