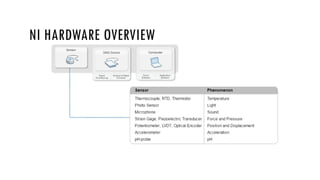

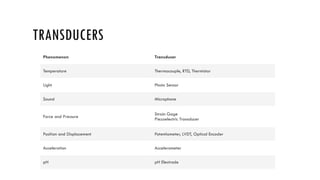

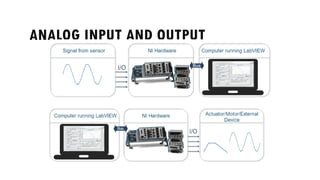

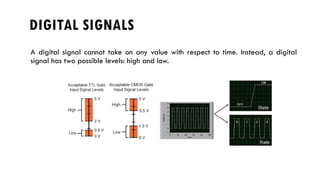

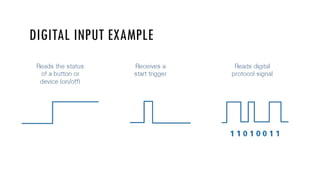

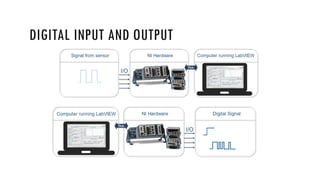

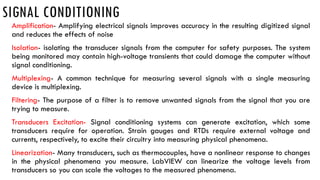

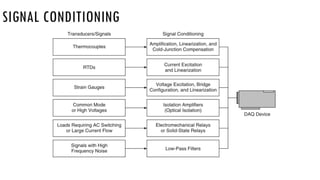

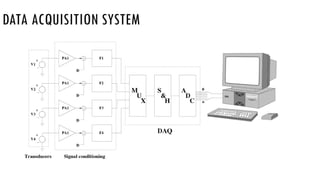

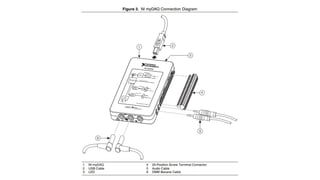

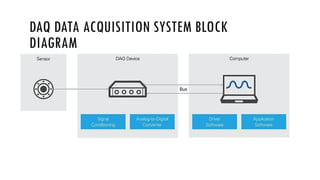

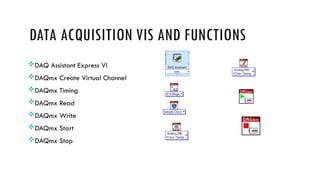

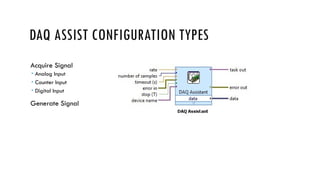

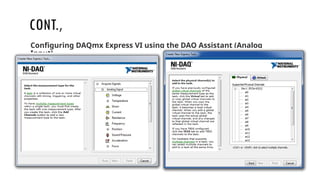

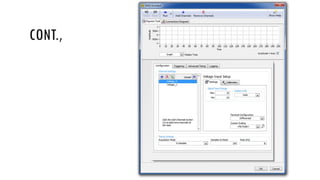

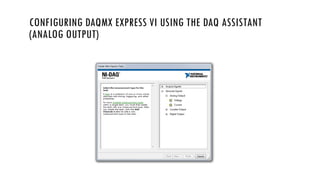

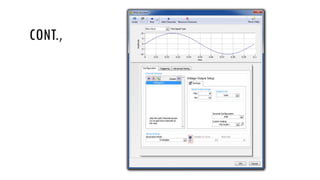

Data acquisition (DAQ) involves sampling signals to measure physical conditions and converting them into digital values for computer manipulation. DAQ systems can utilize various types of hardware interfaces, including USB and Ethernet, to gather data through sensors and transducers for applications in testing and automation. Additionally, signal conditioning is essential for ensuring accurate and safe measurements by amplifying, isolating, and filtering signals before they are digitized.