Embed presentation

Downloaded 33 times

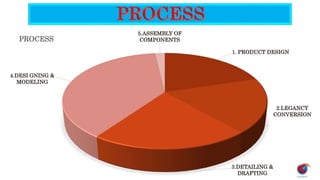

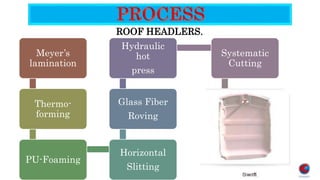

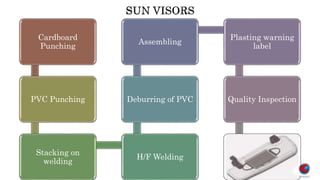

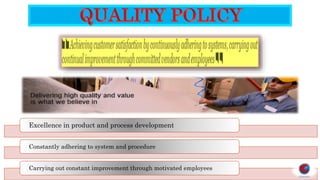

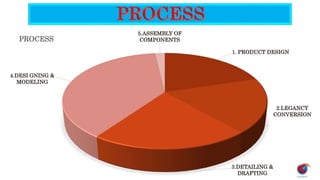

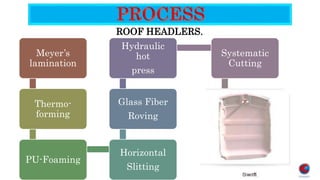

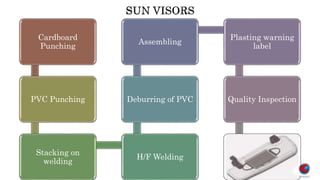

This document provides information about a company that manufactures automotive interior components such as roof headliners, sun visors, and seats. It lists the company's vision, mission, and products. Key details include that the company produces 8,10,000 roof headliners and 13,25,250 sun visors per year for 12 car models. The document also outlines the production processes used to manufacture the components and quality certifications held by the company.