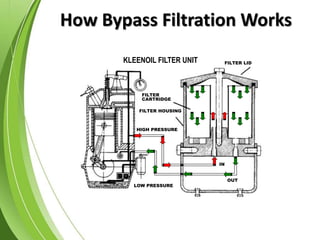

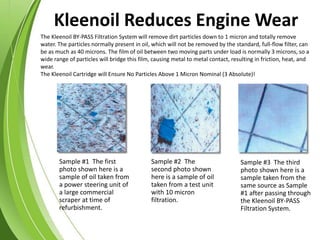

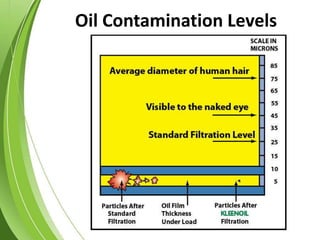

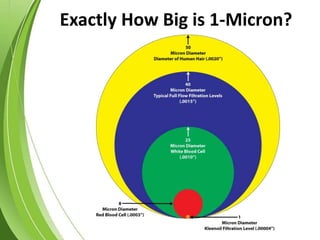

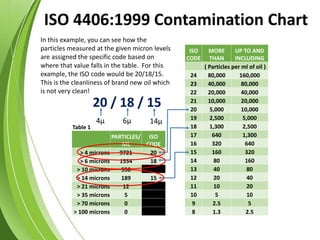

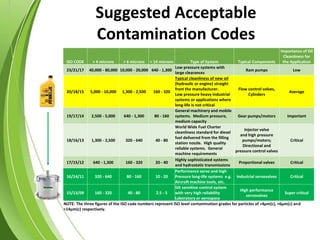

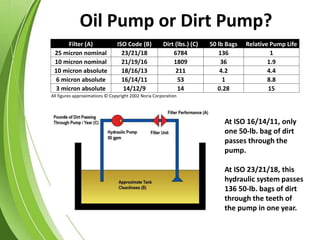

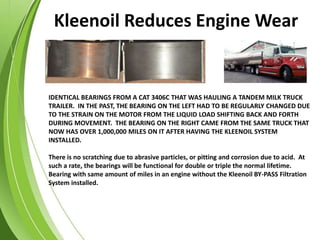

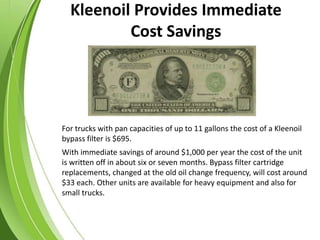

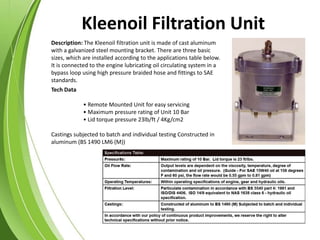

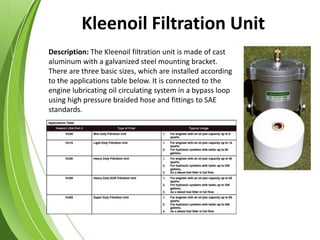

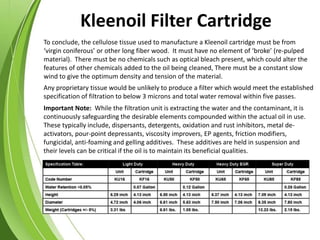

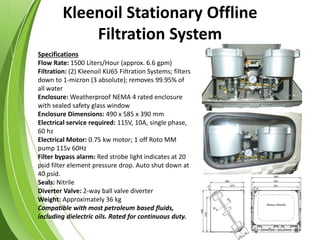

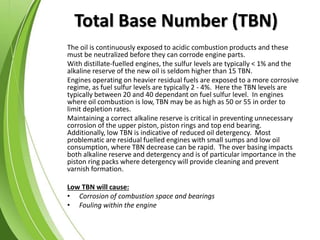

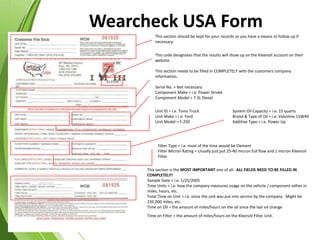

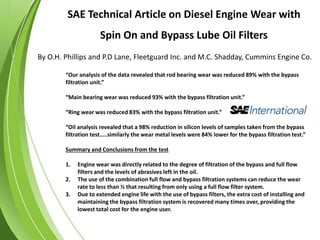

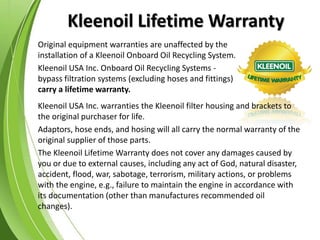

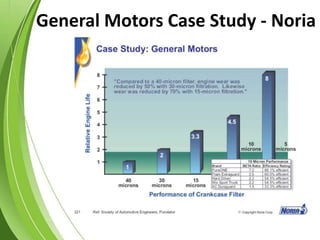

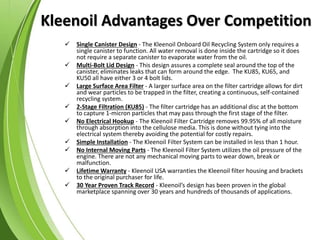

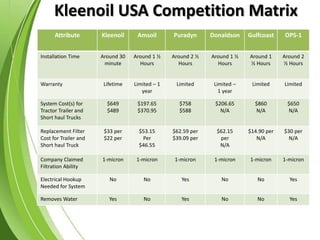

Kleenoil's onboard oil recycling systems dramatically reduce oil usage in OTR trucks by up to 80%, contributing to economic profitability and a smaller carbon footprint. The Kleenoil bypass filtration technology uniquely retains beneficial oil properties while removing contaminants down to 1 micron, extending oil drain intervals and reducing engine wear. This technology has a track record of effectiveness recognized by various industry leaders, promoting resource responsibility and better environmental outcomes.