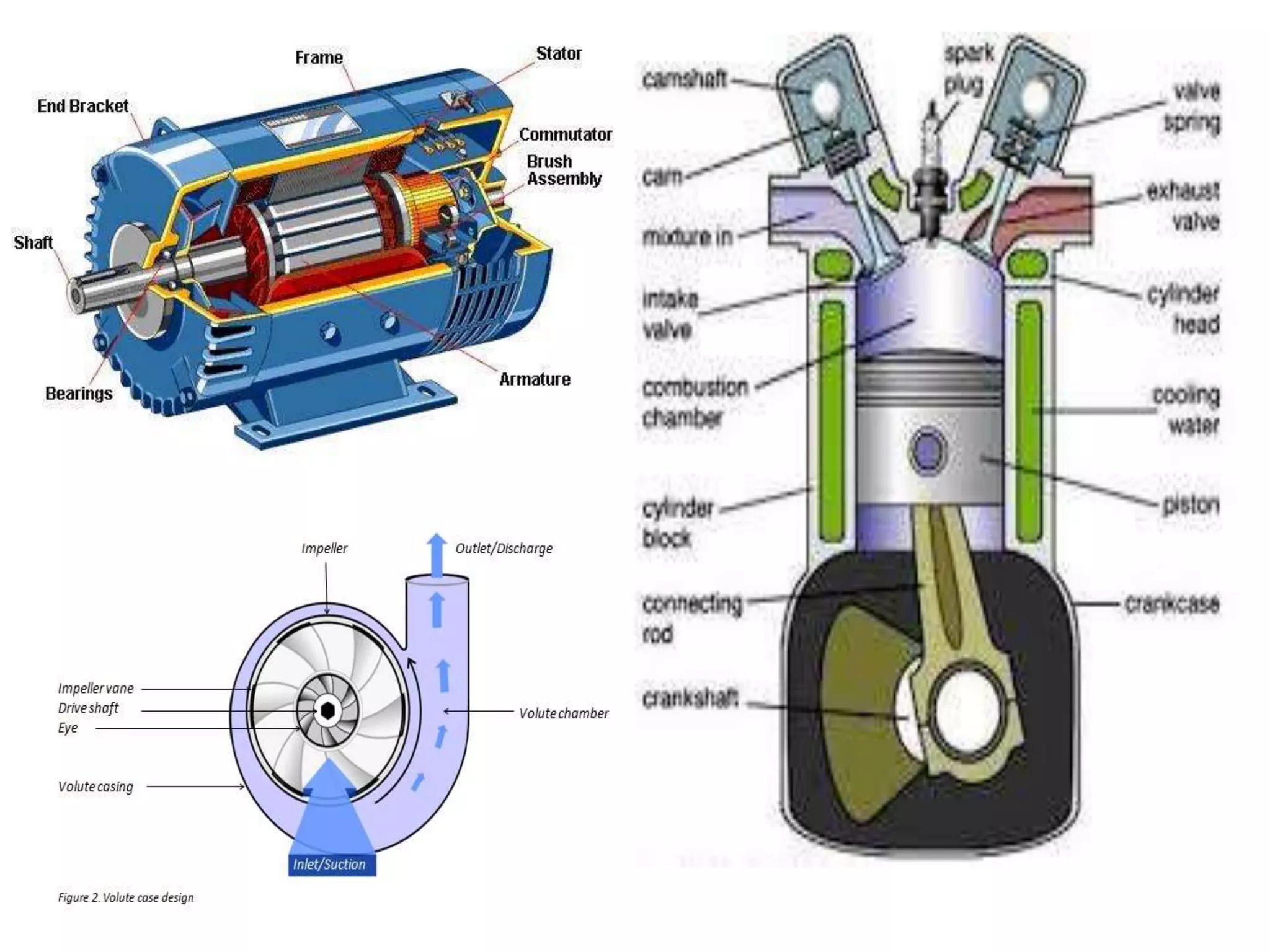

This document provides an introduction to kinematics and machine fundamentals. It defines kinematics as the study of relative motion between machine parts and the forces acting on them. It also defines a machine as a system of kinematically linked components that can transmit power to perform useful work. The document outlines various machine types including those that generate, transmit, and utilize mechanical energy. It distinguishes between machines, mechanisms, and structures. Finally, it discusses kinematic analysis and the graphical and analytical methods used to study motion in machines and mechanisms.