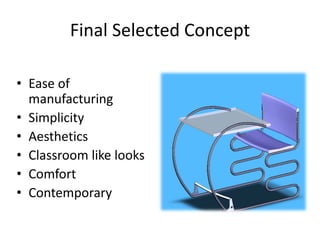

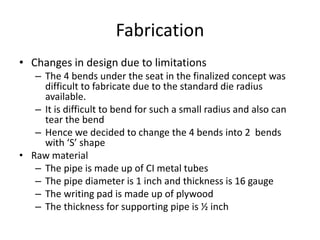

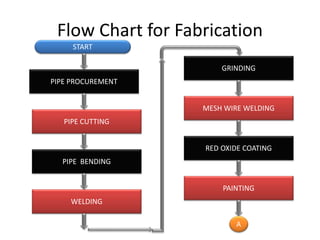

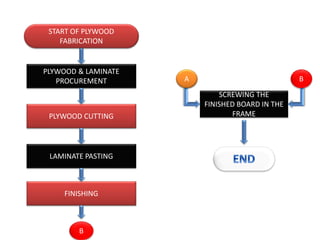

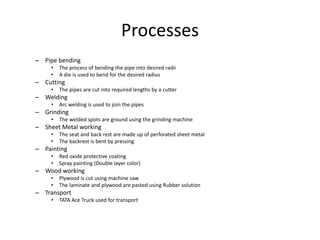

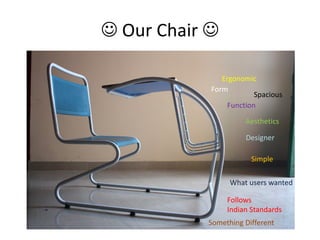

The document summarizes the design and fabrication process of a classroom chair. It describes initial user research, concept generation and selection of a final design. Key aspects of the selected design include ease of manufacturing, simplicity, aesthetics and classroom-like appearance. It then details the fabrication process, including working with a pipe bending manufacturer, design changes made for manufacturability, and finishing steps. Lessons learned focused on the importance of constant communication with manufacturers and addressing challenges that arise during prototyping.