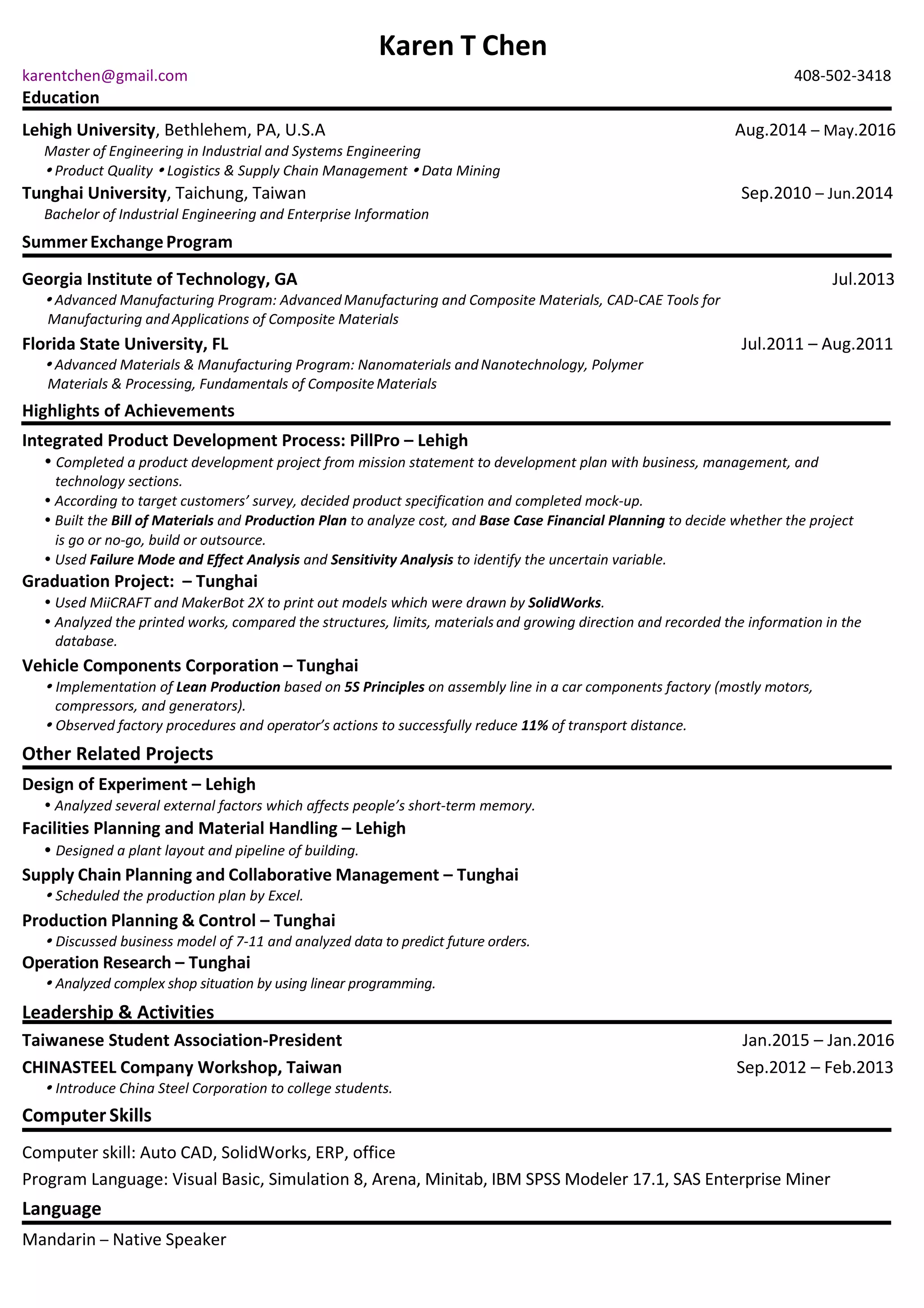

Karen T Chen is seeking a position in industrial engineering. She holds a Master's degree in Industrial and Systems Engineering from Lehigh University and a Bachelor's degree in Industrial Engineering and Enterprise Information from Tunghai University. Her experience includes projects in product development, manufacturing, supply chain management, and operations research. She has skills in CAD/CAE, ERP systems, programming languages, and data analysis software.