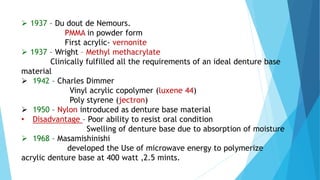

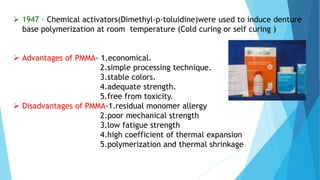

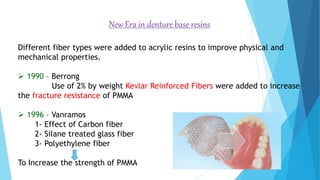

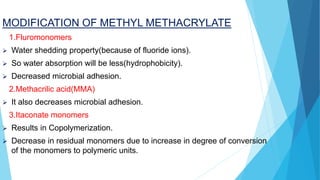

The document reviews the evolution of denture base materials from the 8th century to the 20th century, highlighting the significant transitions from natural materials to synthetic resins. It details the historical context, materials used over time, and modern advancements, including the incorporation of various fibers and thermoplastic resins to enhance strength and performance. The article concludes that computer-aided technology in denture manufacturing presents vast opportunities for future developments in the field.