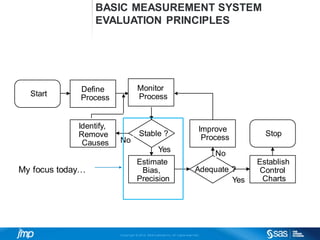

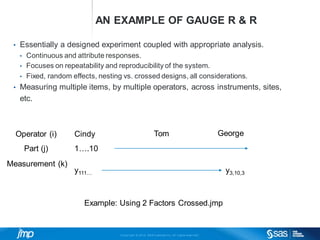

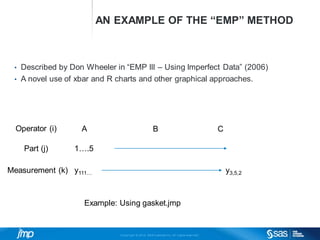

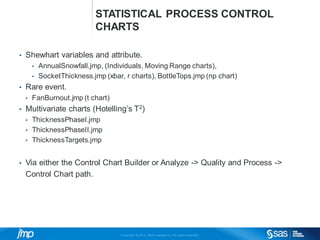

The document outlines key components for evaluating and monitoring processes using measurement system analysis (MSA) and statistical process control (SPC). It details principles of measurement system evaluation, steps for conducting gauge repeatability and reproducibility studies, and methods for monitoring processes with control charts. The content is focused on utilizing JMP software for data analysis and practical applications in process improvement.