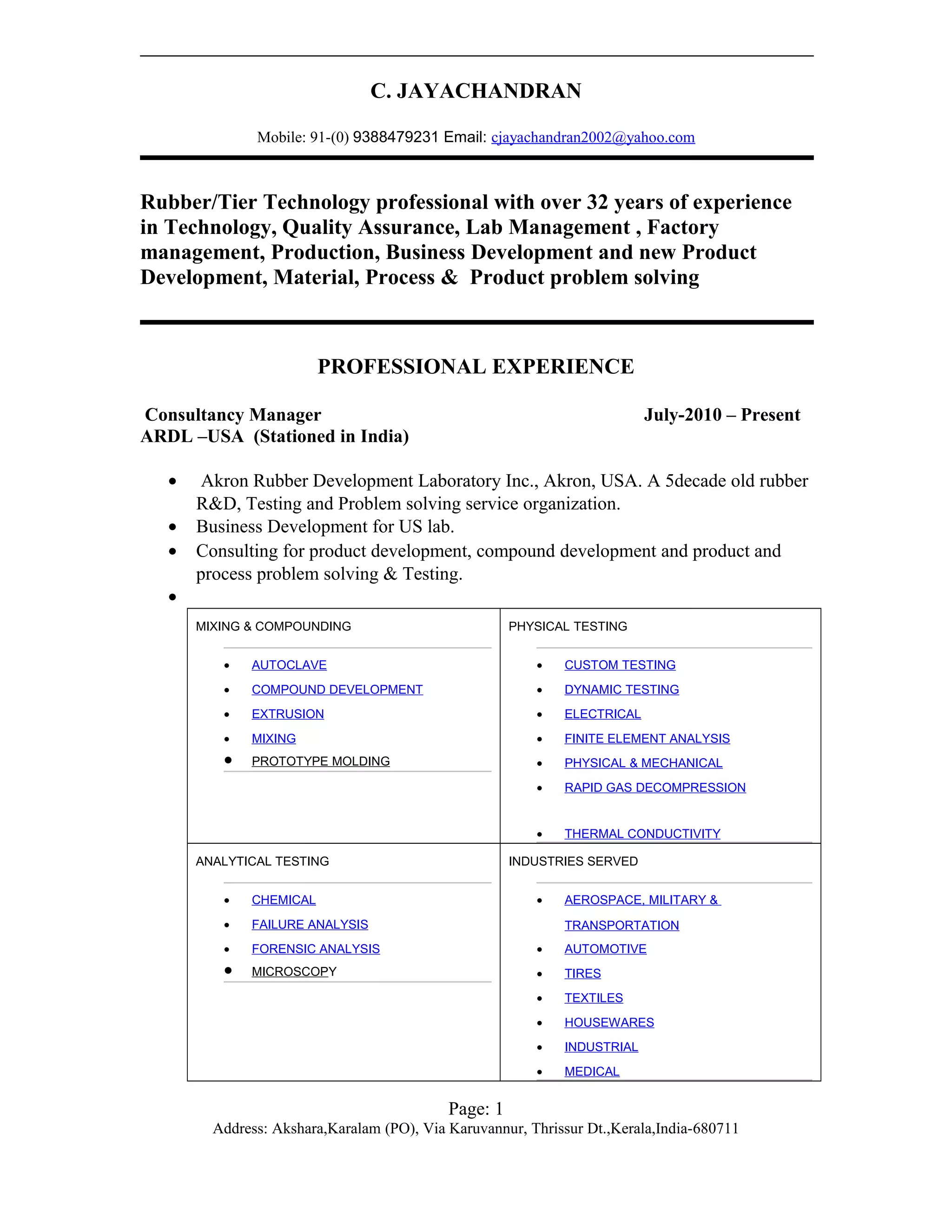

C. Jayachandran has over 32 years of experience in the rubber and tire technology industry. He currently works as a consultancy manager for ARDL-USA, where he provides consulting services for product development, compound development, and problem solving. Previously, he held quality and consultancy management roles at ARDL-India Lab and worked in technology, quality assurance, and management roles for several tire and rubber companies. He has expertise in compound development, testing, process improvement, and quality system implementation.